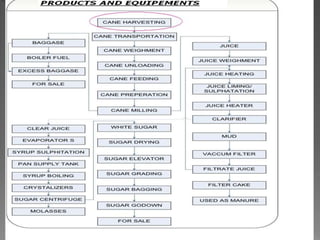

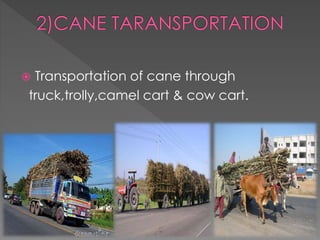

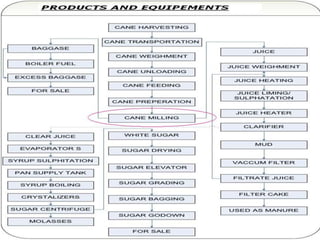

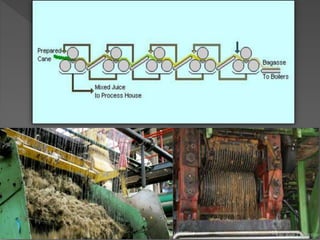

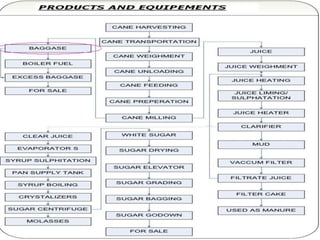

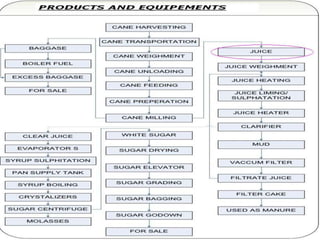

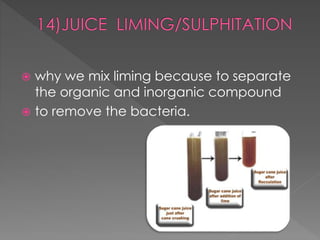

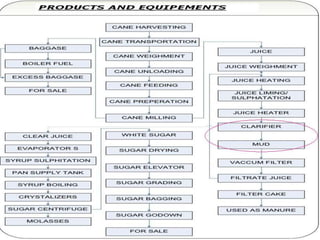

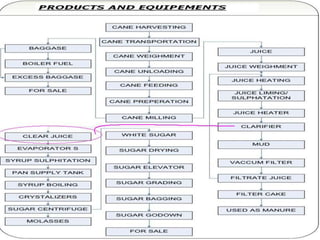

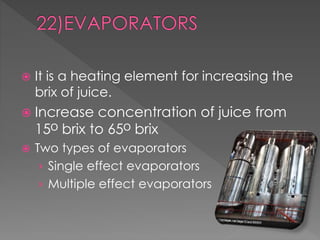

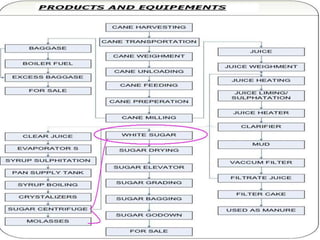

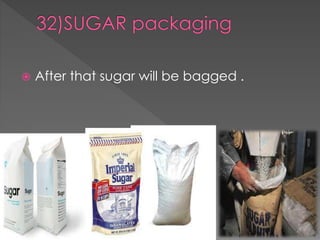

The document describes the process for producing sugar from sugarcane. Sugarcane is transported to the mill and prepared by shredding, hammering, and passing through multiple rollers to extract the juice. The juice is heated, filtered, concentrated in evaporators, and crystallized. It is then centrifuged to separate sugar crystals from molasses. The sugar crystals are further dried and separated by size before bagging and storage. Key steps include juice extraction, heating and filtering, concentration, crystallization, centrifugation, and final processing. Quality control of temperature, moisture and grain size is important to optimize sugar production.