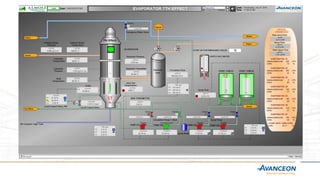

The document discusses automation in the sugar production process. It provides an overview of the key stages in sugar production from cane unloading to bagging. It then discusses in detail the automation of evaporation and pans using the example of a project at Al-Moiz Industries. Automation provides benefits like improved recovery rates, reduced costs and manpower, and consistent quality. The evaporation and pan automation controls critical parameters like temperature, level, flow and pressure to optimize efficiency.