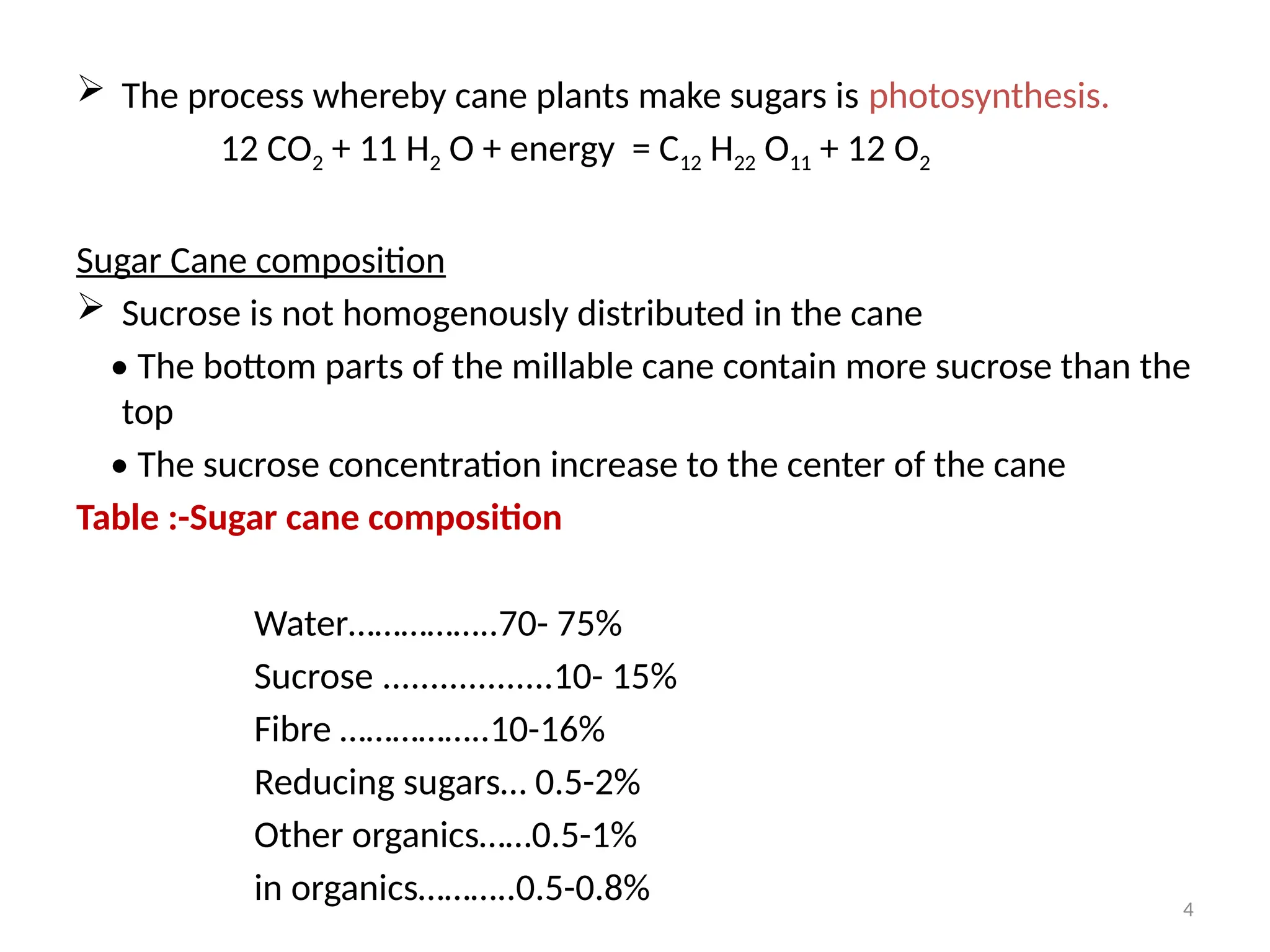

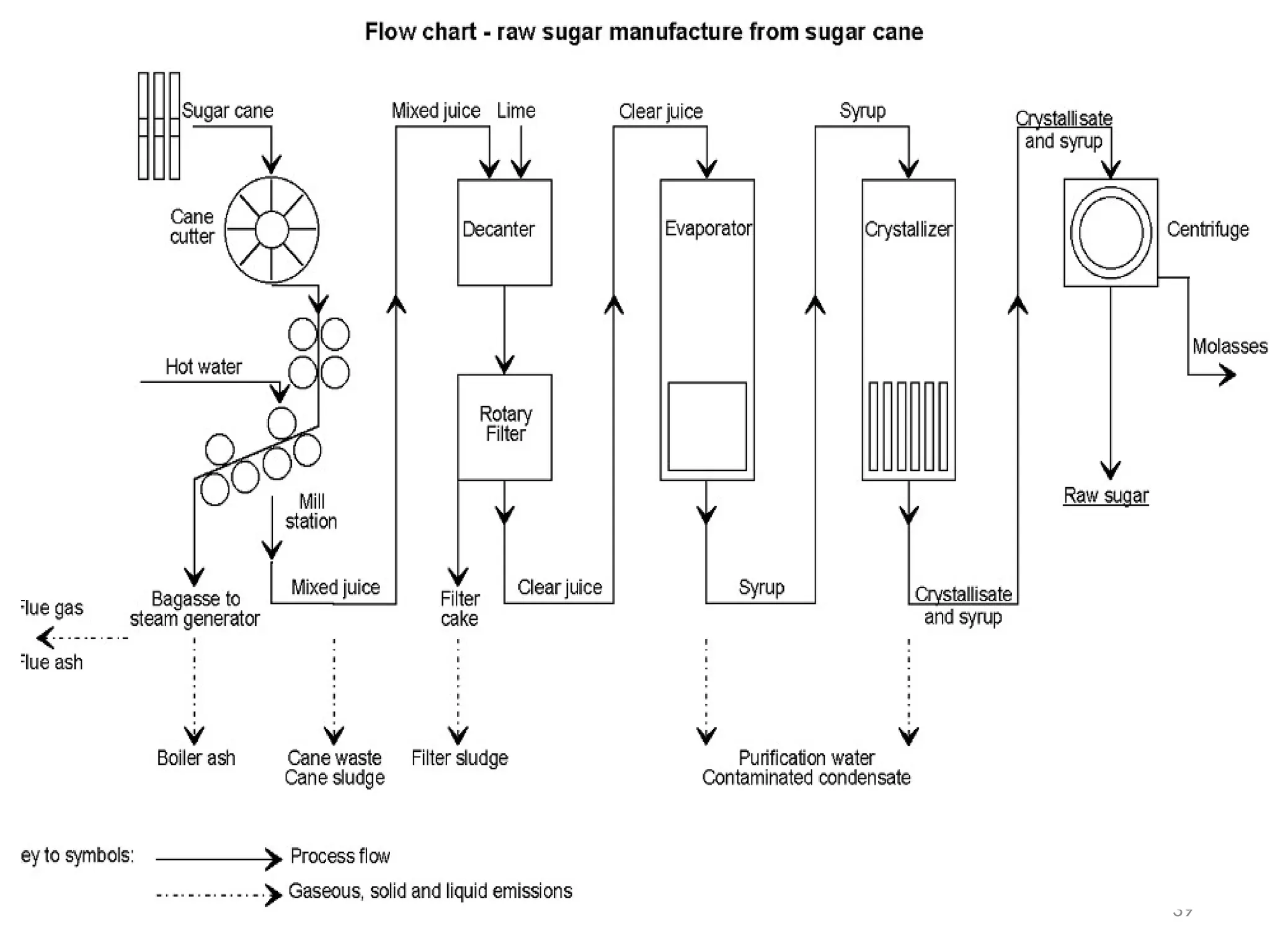

The document outlines the process of sugar production from sugar cane, detailing the main stages such as harvesting, juice extraction, purification, and crystallization. It also discusses raw materials, equipment, and by-products, emphasizing the importance of sucrose content and efficient processing methods to maximize yield. Furthermore, it highlights the utilization of by-products like bagasse, molasses, and filter cake for economic and environmental benefits.