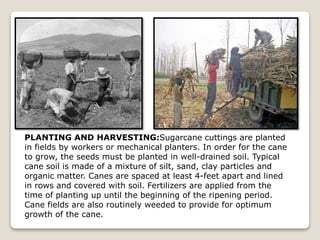

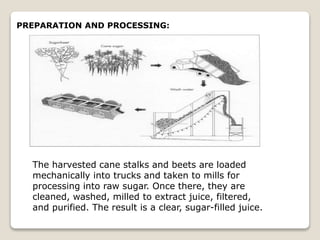

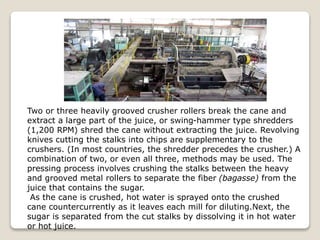

The document describes the sugar manufacturing process from planting sugarcane to packing final sugar products. It details each stage including planting, harvesting, processing, purification, crystallization, and packing. Various machines and methods are utilized throughout the process to ensure efficient extraction and refinement of sugar from raw cane.