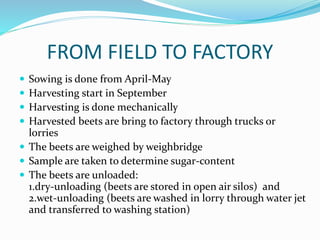

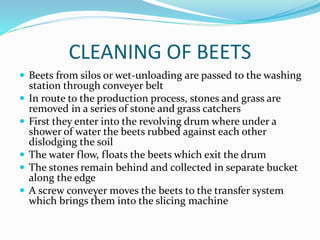

The document summarizes the process of sugar production from sugar beets. Key steps include harvesting beets from fields, cleaning and slicing beets, extracting sugar through diffusion with hot water, purifying juice through lime and carbonation, concentrating juice in evaporators, crystallizing sugar and separating it from molasses through centrifugation, and further processing molasses to extract remaining sugar. The finished sugar is then packaged, stored, and shipped for export.