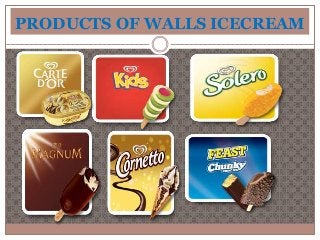

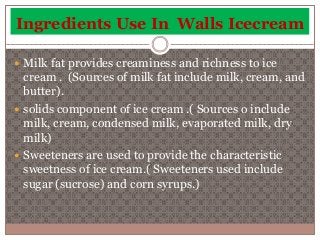

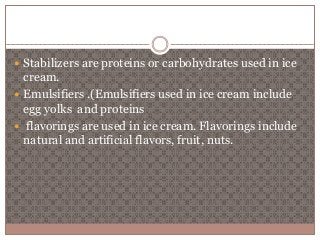

The document discusses the art of finding happiness in everyday items, specifically focusing on Walls ice cream, which is a frozen blend of cream, air, and flavorings. It outlines the manufacturing process, ingredients, and the challenges faced, including high costs and health implications. Suggestions are made to reduce the fat and sugar content for better health outcomes and to reconsider pricing strategies.