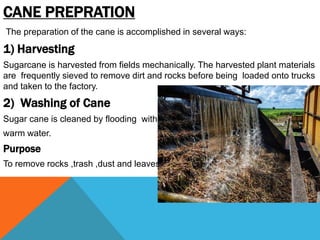

This document provides information about the sugar industry in Pakistan. It discusses the history of sugar mills in Pakistan, the importance of the sugar industry, the manufacturing process of sugar including cane preparation, juice extraction, purification and crystallization. It also discusses factors affecting sugar production such as fertilizers and burning cane, and ways to improve sugar production such as utilizing byproducts, using organic fertilizers, paying farmers higher prices, and adopting green technologies.