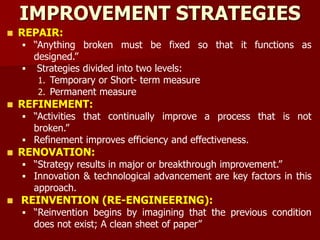

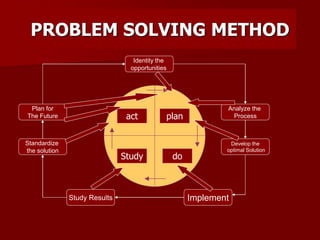

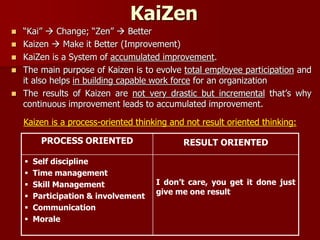

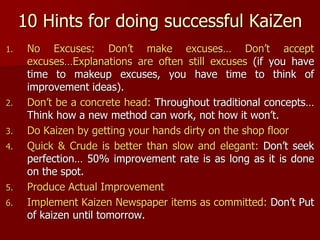

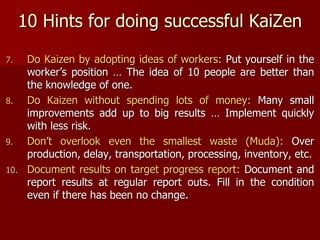

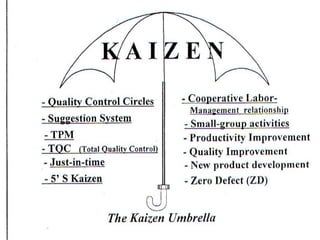

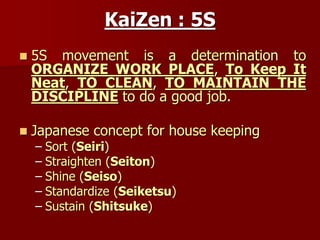

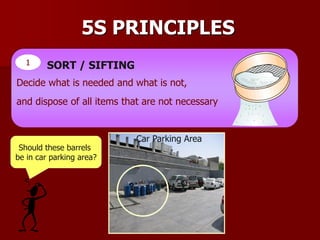

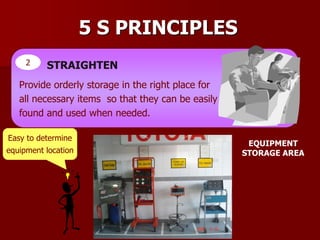

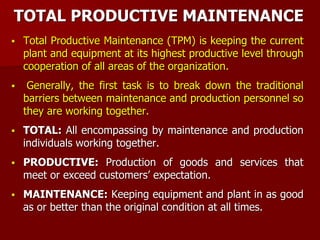

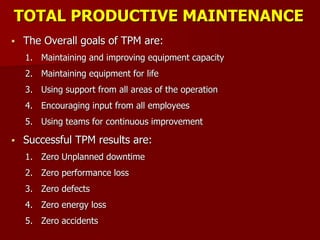

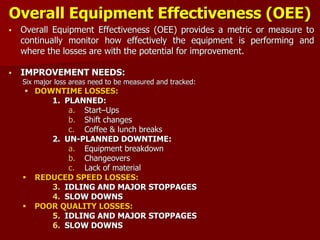

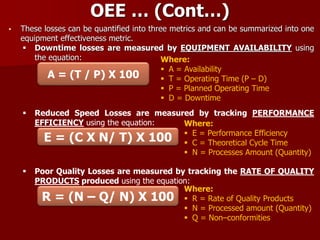

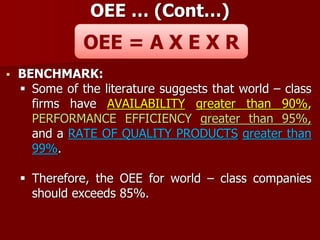

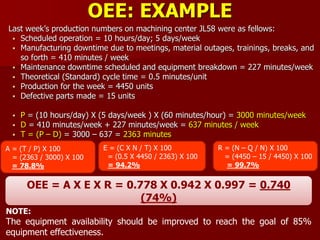

This document provides an overview of total quality management approaches and improvement strategies. It discusses four improvement strategies: repair, refinement, renovation, and reinvention. It also outlines quality improvement frameworks like Kaizen, Six Sigma, and benchmarking. Key aspects of Kaizen are explained, including its focus on continual small improvements rather than large changes. The 5S methodology for organizing and standardizing the workplace is described. Total productive maintenance aims to keep equipment in top condition through cooperation between maintenance and production teams. Overall equipment effectiveness is a metric that measures availability, performance efficiency, and quality rate to monitor losses and improvement opportunities.