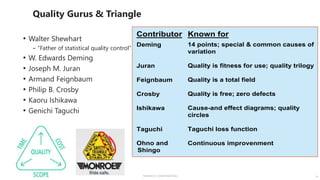

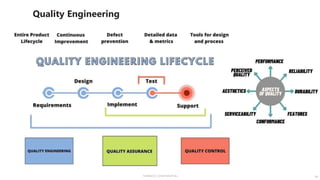

The document provides an overview of quality, including its history and importance. It discusses the evolution of quality practices from the Industrial Revolution through modern approaches like Total Quality Management and Six Sigma. Key figures who advanced quality concepts are also highlighted. The document then covers quality certifications, dimensions of quality, costs of quality, and problem-solving methodologies like the PDCA cycle.