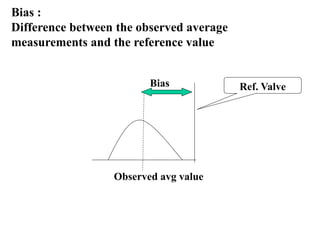

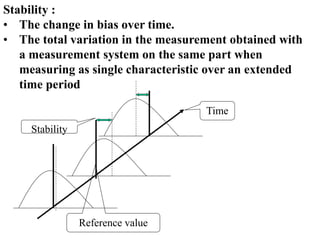

This document discusses measurement system analysis (MSA), which assesses the quality of measurement systems that generate measurements critical to a facility's operations. MSA applies statistical methods to evaluate six key properties (repeatability, reproducibility, accuracy, bias, linearity, stability) that characterize a measurement system's variation. Conducting an MSA is important when a new measuring device is introduced, to compare measurement devices, or when required by a customer's control plan. The document outlines methods like variable and attribute gauge studies to evaluate a measurement system, and provides acceptance criteria to determine if a system is acceptable based on the percentage of variation attributed to the gauge.

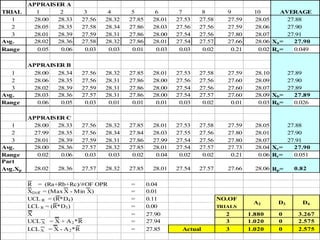

![REPEATABILITY-EQUIPMENT VARIATION(EV)

TRIAL: K1

2 0.8862

EV = R*K1 = 0.0248 3 0.5908

3 0.5908

REPRODUCIBILITY-APPRAISER VARIATION

OPERATOR : K2

AV = [(Xdiff*K2)2

-(EV2

/nr)] 2 0.7071

AV = 0.00 3 0.5231

3 0.5231

REPEATABILITY & REPRODUCIBILITY

R&R = (EV2

+ AV2

)

R&R = 0.02

PART VARIATION (PV)

PV = Rp*K3 = 0.26

PART K3

TOTAL VARIATION (TV) 2 0.7071

TV = (R&R2

+ PV2

) 3 0.5231

TV = 0.26 4 0.4467

% EV = 10 5 0.4030

6 0.3742

% AV = 0 7 0.3534

8 0.3375

% R&R = 10 9 0.3249

10 0.3146

% PV = 100 10 0.3146

Actual

Actual

MEASUREMENT UNIT ANALYSIS

Actual](https://image.slidesharecdn.com/msa5day-191004151429/85/MSA-26-320.jpg)