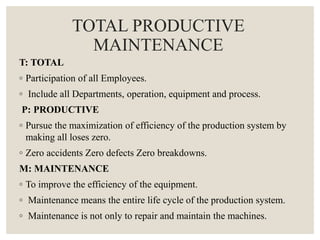

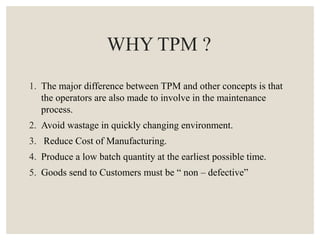

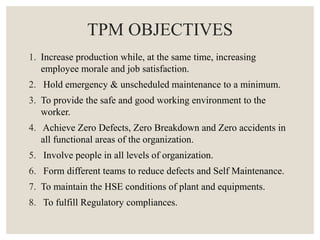

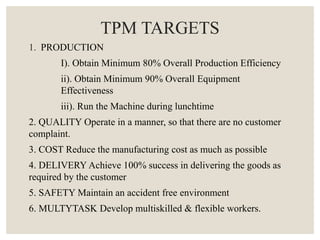

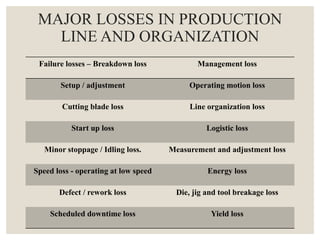

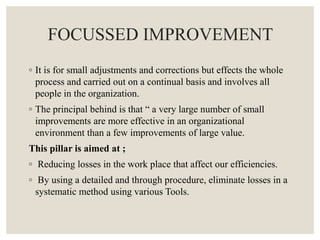

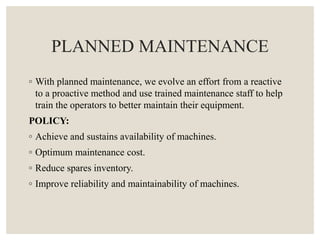

Total Productive Maintenance (TPM) emphasizes the total participation of all employees to maximize efficiency, reduce costs, and achieve zero defects, breakdowns, and accidents. Key objectives include increasing production, maintaining a safe working environment, and fostering teamwork while targeting various types of maintenance and addressing productivity losses. The method is structured around five pillars—autonomous maintenance, focused improvement, planned maintenance, quality maintenance, and education/training—to ensure continuous improvement in manufacturing processes.