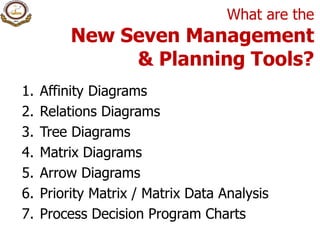

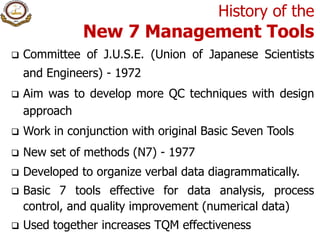

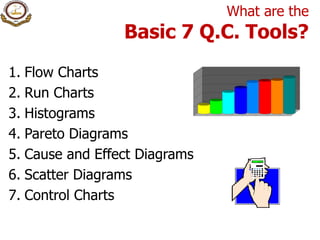

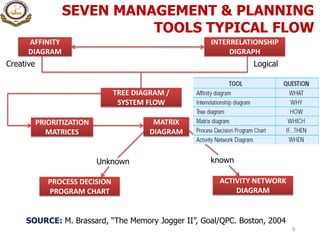

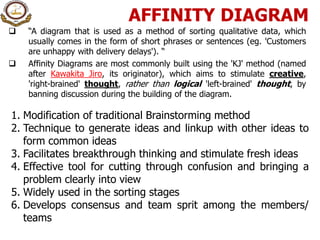

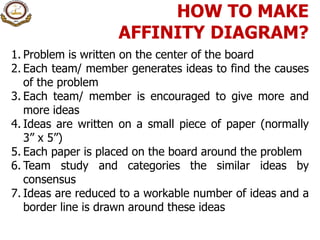

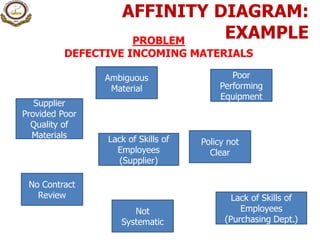

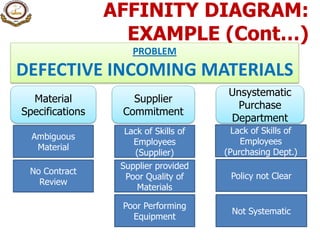

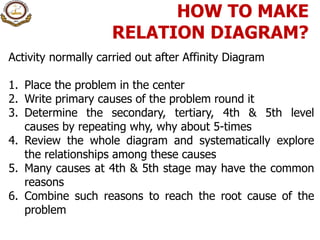

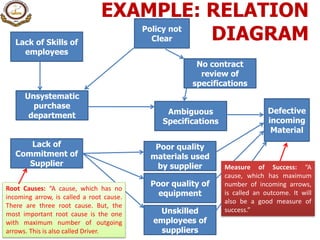

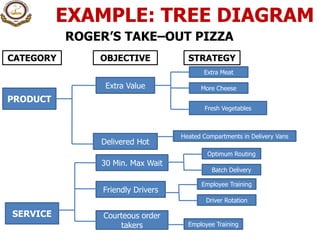

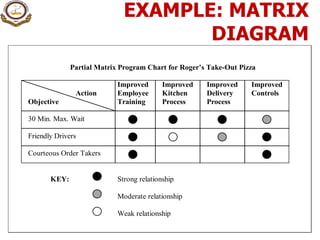

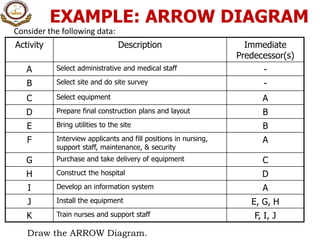

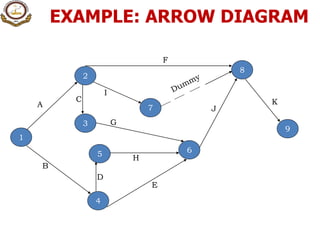

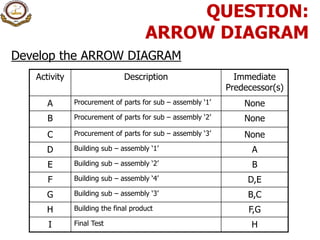

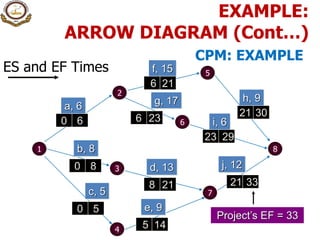

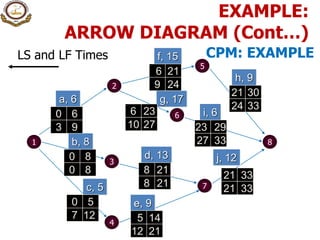

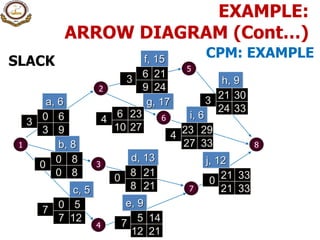

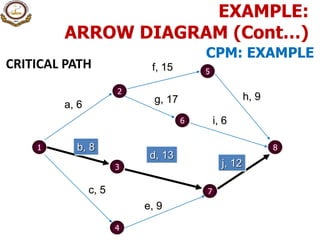

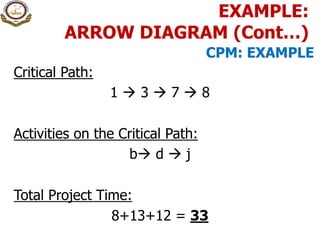

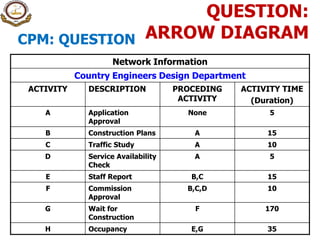

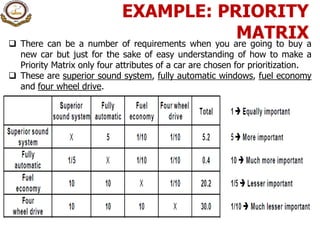

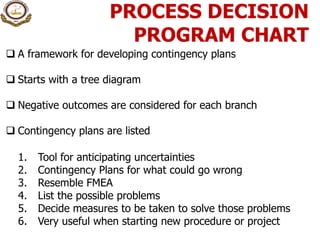

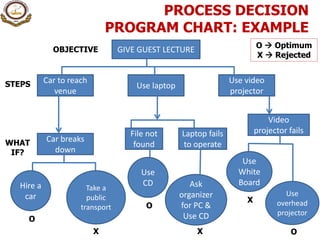

The document discusses various quality tools and techniques, including the New Seven Management Tools and the Basic Seven QC Tools. It provides details on each of the New Seven Tools: Affinity Diagrams, Relationship Diagrams, Tree Diagrams, Matrix Diagrams, Arrow Diagrams, Priority Matrix, and Process Decision Program Charts. Examples and steps to create each tool are outlined. The relationship between the New Seven Tools, which organize verbal data, and the Basic Seven QC Tools, which analyze numerical data, is explained.