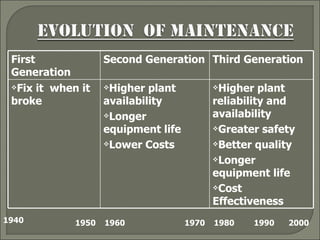

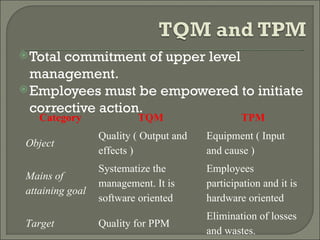

Total productive maintenance (TPM) involves all employees and departments working together to improve equipment effectiveness and maximize production efficiency. The goals are to eliminate equipment failures, reduce waste, and improve product quality. TPM aims to improve equipment reliability through autonomous, proactive maintenance carried out by operators. This shifts maintenance from being reactive to being predictive and preventive. When implemented successfully, TPM results in higher equipment availability, productivity, and employee morale while lowering costs.