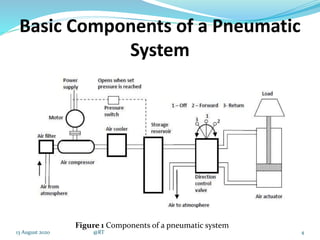

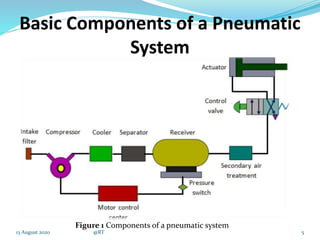

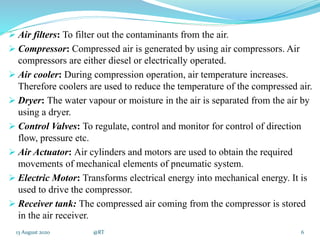

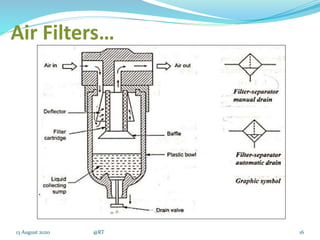

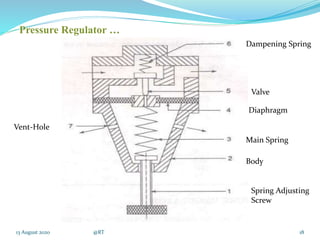

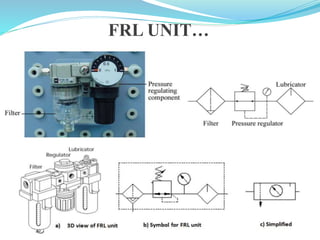

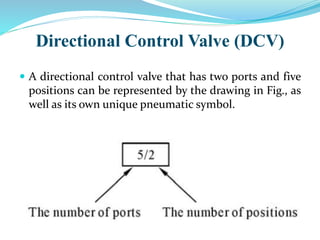

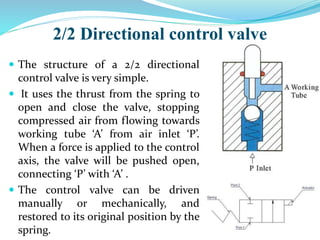

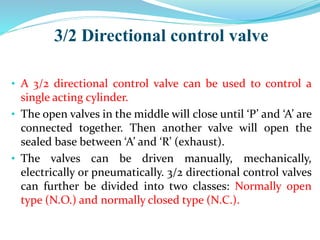

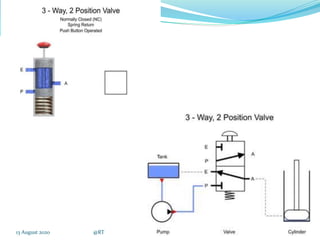

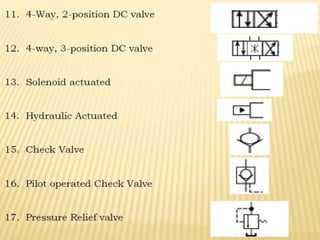

This document provides an introduction to pneumatic systems, outlining their basic components, advantages, and disadvantages. Pneumatic systems utilize compressed air for energy transmission and control, with components including compressors, control valves, and execution components like cylinders. The document details the functions of major pneumatic components, their operation, and relevant pneumatic symbols for understanding system design.