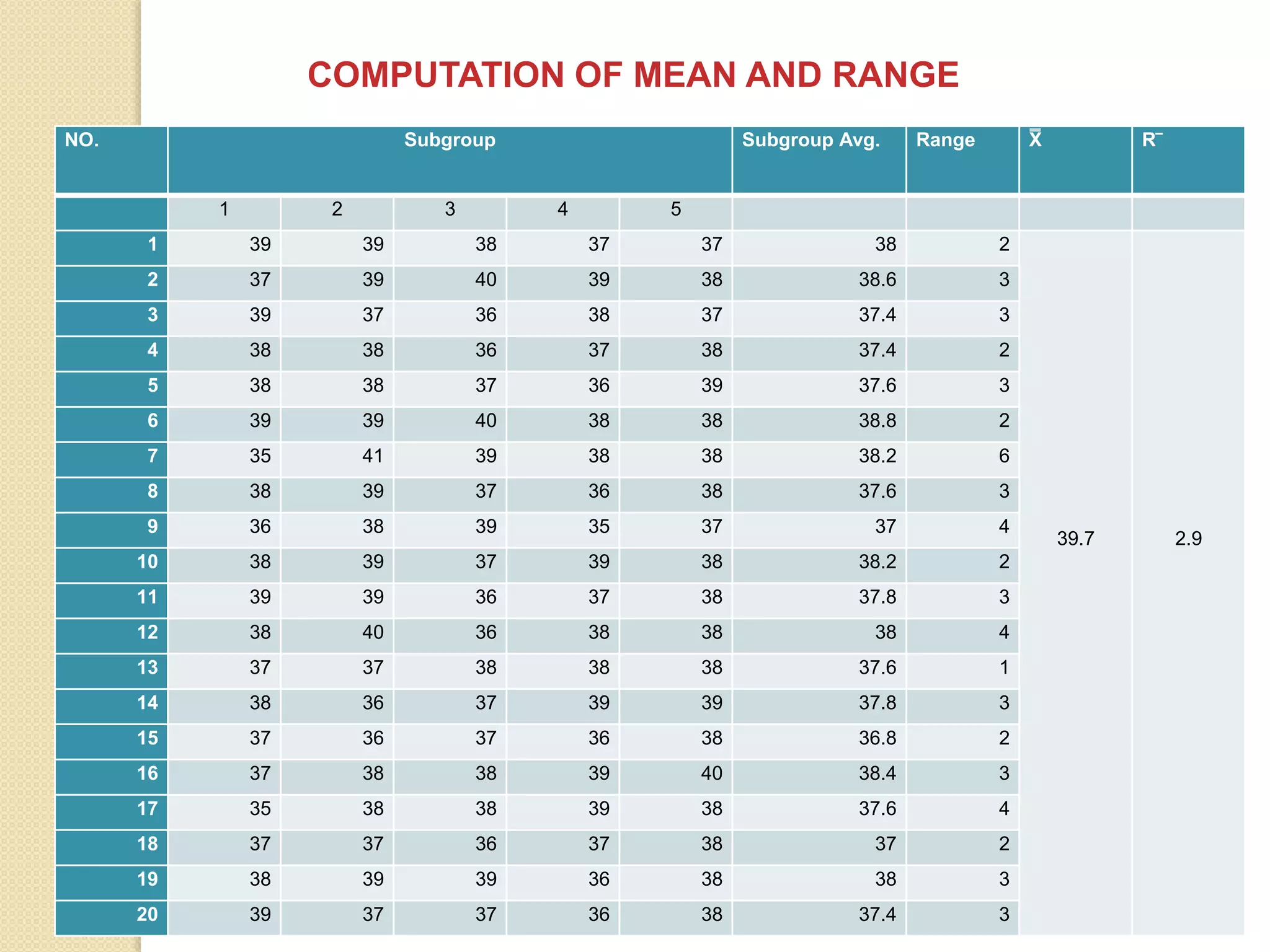

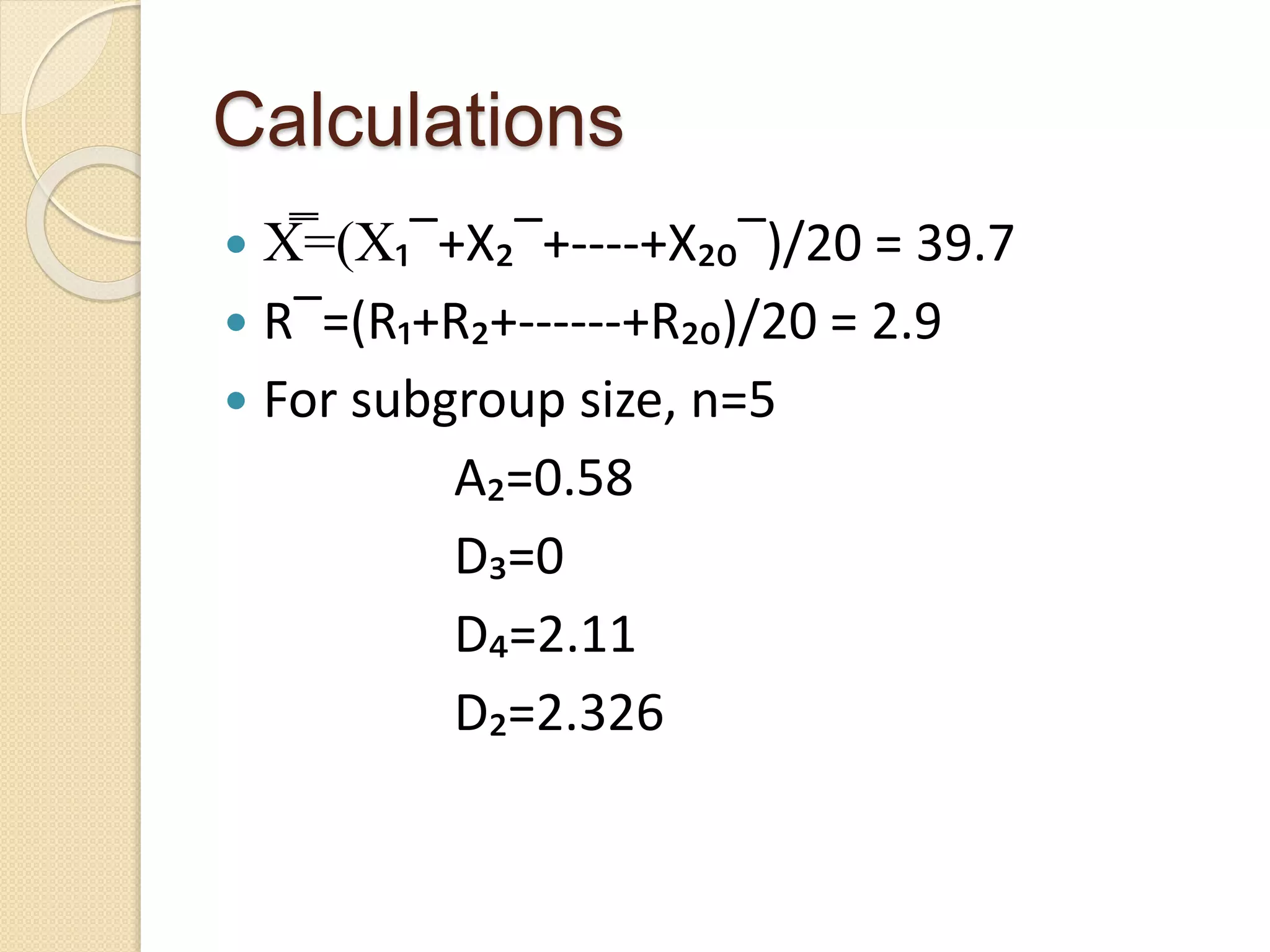

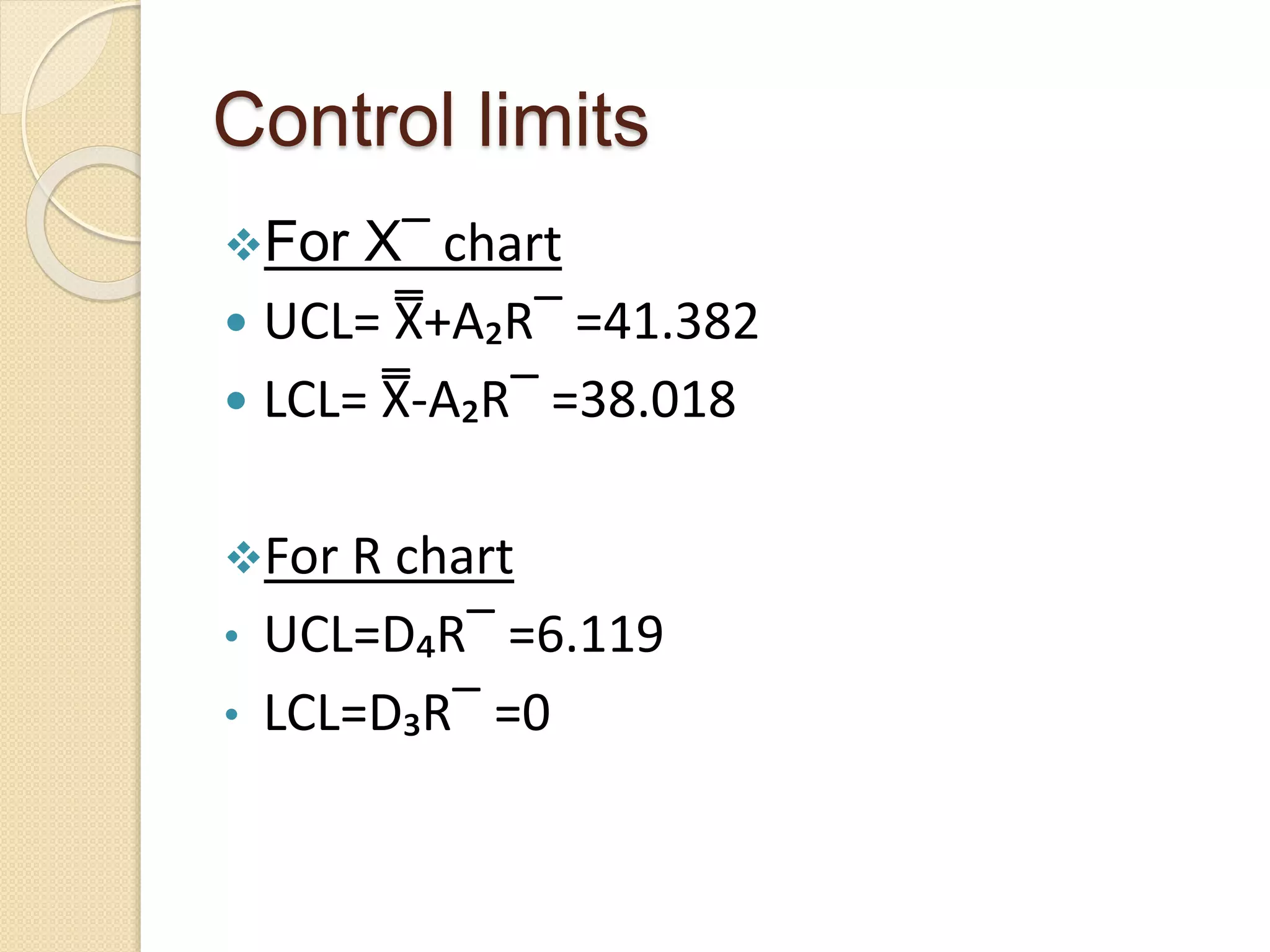

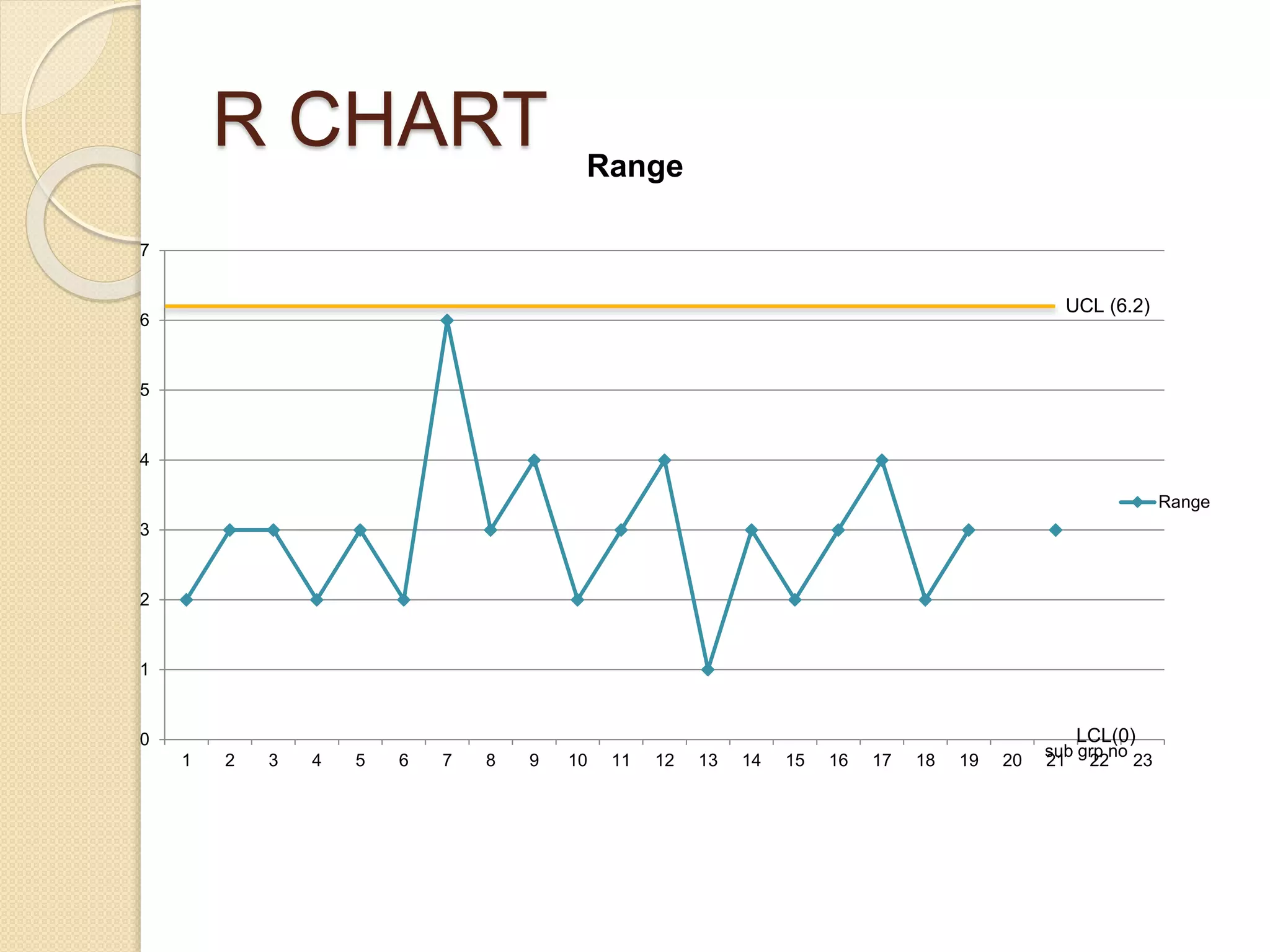

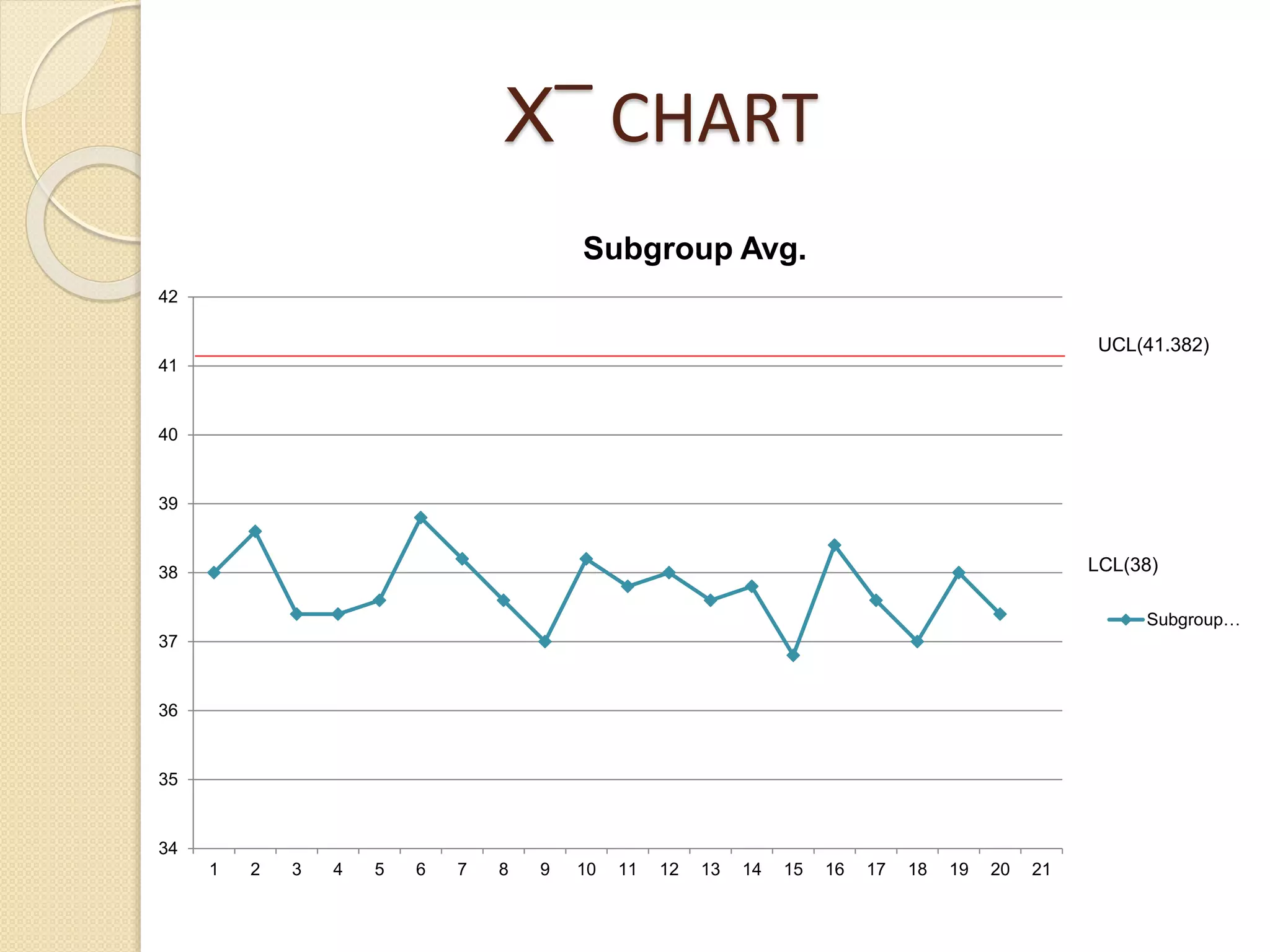

The document discusses the construction and application of x̅ and R control charts for monitoring process average and variation in quality control. It details step-by-step procedures for calculating sample averages and ranges, constructing charts, and analyzing a case study involving 100 work pieces to determine process control limits. The final findings indicate that the process is under control, with all points lying within revised control limits.