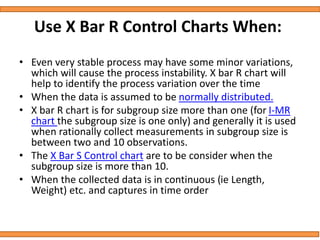

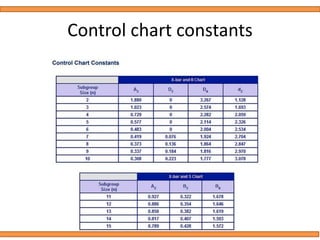

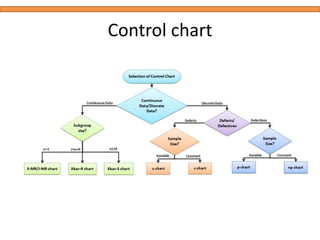

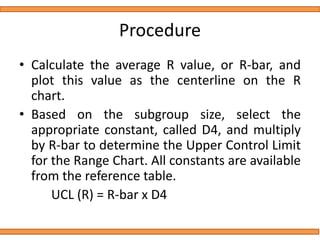

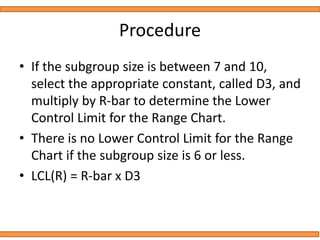

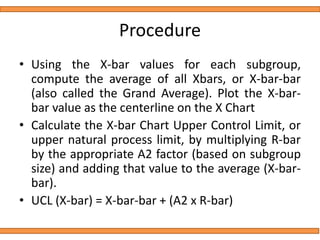

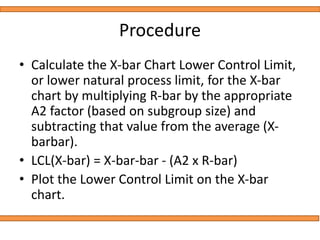

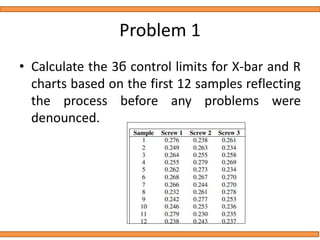

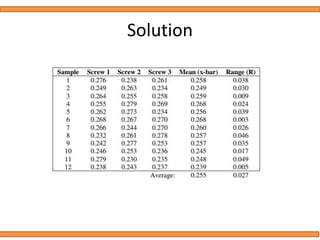

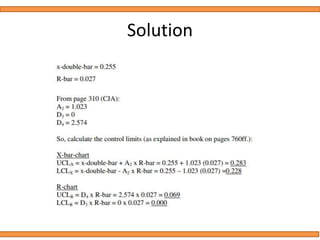

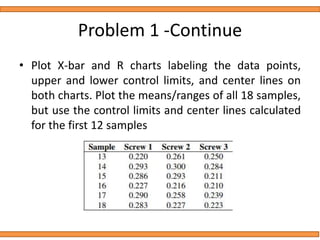

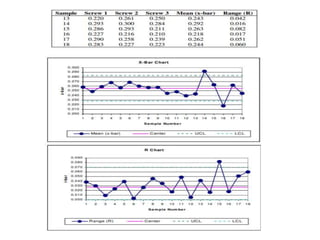

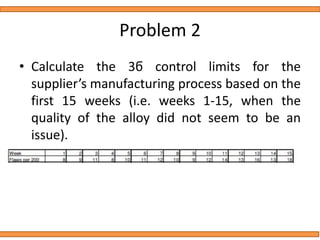

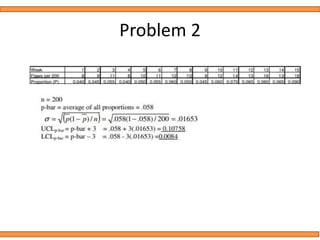

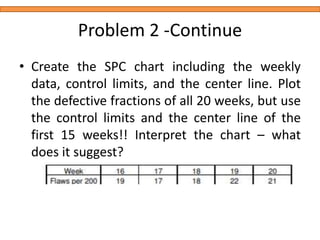

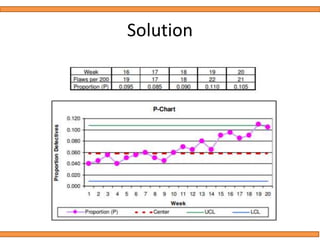

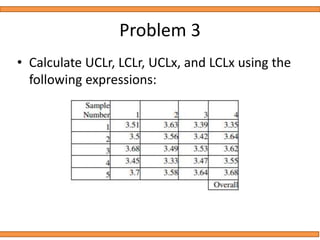

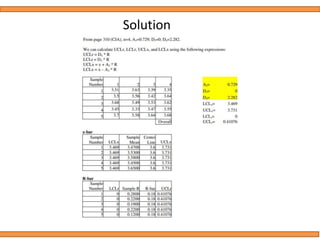

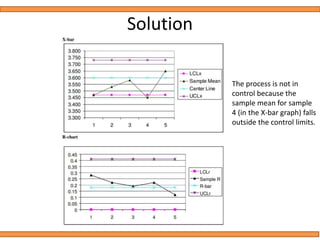

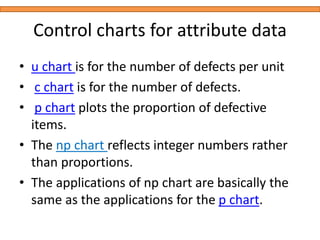

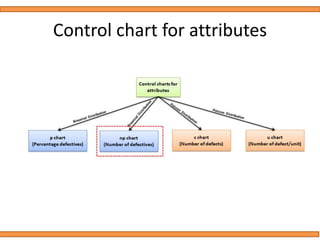

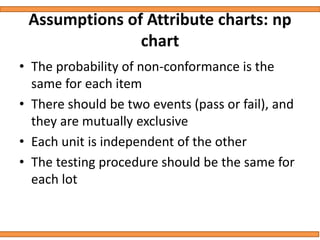

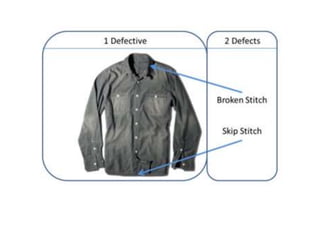

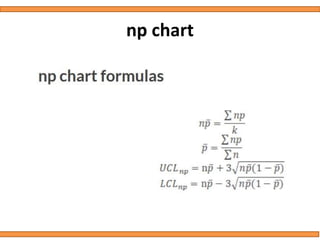

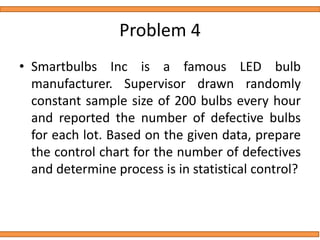

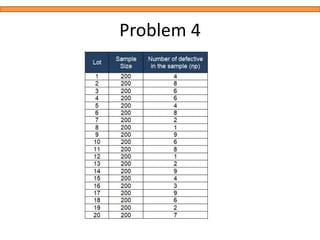

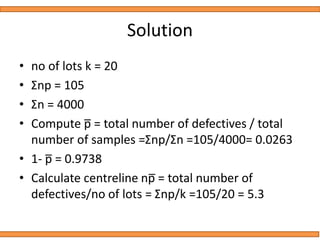

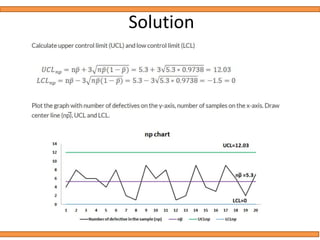

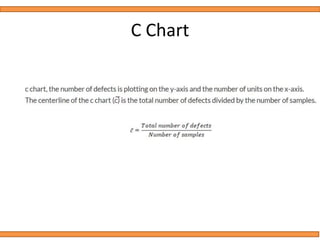

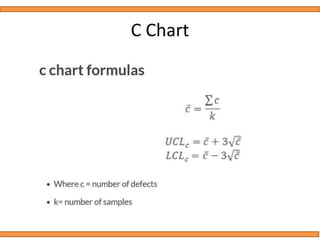

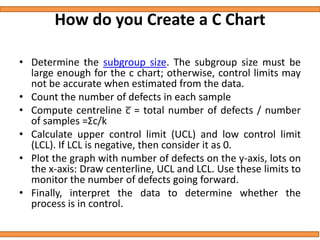

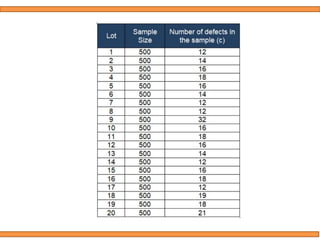

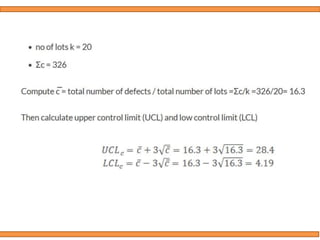

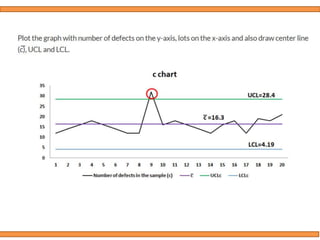

This document discusses statistical quality control using x-bar and r charts to monitor process variations over time, emphasizing the importance of subgroup sizes and control limits. It includes step-by-step procedures for calculating control limits and interpreting charts, along with examples of problems related to quality control in manufacturing processes. It also introduces np, c, and p charts for tracking defects and provides guidance on the creation and analysis of these charts.