The document discusses measurement system analysis (MSA) which is used to evaluate measurement systems and understand sources of variation. Key points:

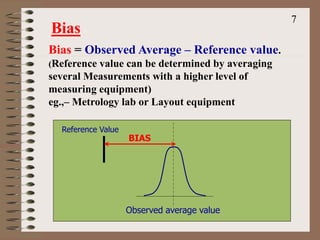

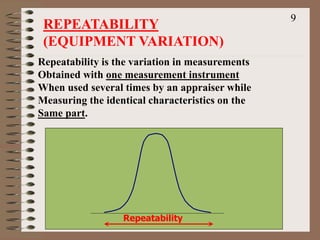

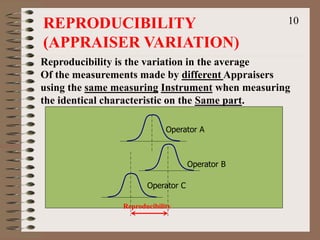

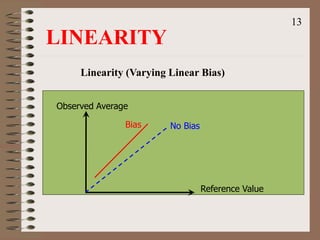

- MSA assesses measurement quality and identifies sources of error like bias, repeatability, reproducibility, stability, and linearity.

- It is required to make informed process adjustments and avoid wrong decisions from low quality measurement data.

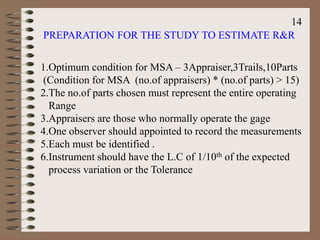

- MSA studies involve multiple appraisers measuring multiple parts multiple times to calculate variation percentages.

- A sample MSA study shows data collection, calculations for repeatability, reproducibility, and overall variation to evaluate the measurement system.

![A

B

C

PART

1 2 3 4 5 6 7 8 9 10

1 9.490 9.490 9.490 9.480 9.480 9.470 9.480 9.470 9.490 9.480 9.482

2 9.490 9.480 9.490 9.490 9.480 9.480 9.490 9.490 9.490 9.490 9.487

3 9.490 9.480 9.490 9.490 9.480 9.480 9.490 9.490 9.490 9.490 9.487

9.490 9.483 9.490 9.487 9.480 9.477 9.487 9.483 9.490 9.487 Xa= 9.4853

0.000 0.010 0.000 0.010 0.000 0.010 0.010 0.020 0.000 0.010 Ra= 0.0070

1 9.470 9.470 9.480 9.470 9.460 9.480 9.490 9.480 9.480 9.470 9.475

2 9.490 9.470 9.470 9.490 9.480 9.490 9.480 9.480 9.480 9.480 9.481

3 9.470 9.470 9.490 9.470 9.480 9.480 9.490 9.470 9.480 9.490 9.479

9.477 9.470 9.480 9.477 9.473 9.483 9.487 9.477 9.480 9.480 Xb= 9.4783

0.020 0.000 0.020 0.020 0.020 0.010 0.010 0.010 0.000 0.020 Rb= 0.0130

1 9.470 9.470 9.480 9.480 9.470 9.480 9.470 9.470 9.470 9.460 9.472

2 9.480 9.460 9.470 9.470 9.470 9.480 9.470 9.470 9.480 9.480 9.473

3 9.480 9.480 9.470 9.480 9.470 9.470 9.480 9.480 9.470 9.470 9.475

AVERAGE 9.477 9.470 9.473 9.477 9.470 9.477 9.473 9.473 9.473 9.470 Xc= 9.4733

RANGE 0.010 0.020 0.010 0.010 0.000 0.010 0.010 0.010 0.010 0.020 Rc= 0.0110

PART AVERAGE (Xp) 9.481 9.474 9.481 9.480 9.474 9.479 9.482 9.478 9.481 9.479 Rp= 0.0078

Xp = 9.4790

R = 0.0103

X Diff = Max X - Min X X Diff= 0.0120

UCL (R) = D4 X R D4 = 2.575 0.0266

LCL (R) = D3 X R D3 = 0.000 0

UCL (x ) = [Xp + A2R] A2 = 1.023 9.4896

LCL (x ) = [Xp - A2R] 9.4684

AVERAGE

RANGE

C

Xp = [ Xa + Xb +Xc] / 3

A

AVERAGE

RANGE

B

OPERATOR TRIAL NO. AVERAGE

Specification Gauge Least Count 0.02mm

Characteristic Gauge Type -----

Part Name Fuel pump Gauge Name V.C

GAUGE REPEATABILITY AND REPRODUCIBILITY DATA SHEET

Part No. HA196100-3101 Gauge No. XXXXX Operator Name (s)

R = [ Ra + Rb +Rc] / 3

17](https://image.slidesharecdn.com/msatraining-191018130659/85/Msa-training-17-320.jpg)

![Doc. No. Written

Line Name

Date YYYY MM DD

No. of Trials 3 3 10

1

2

3

R

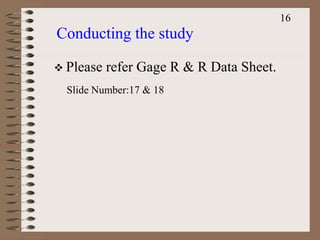

REPEATABILITY - EQUIPMENT VARIATION (EV)

R = 0.0103 % EV = 100 [EV/TV]

K1 = 3.05 Trials K1

EV = R X K1 2 4.56 = 68%

= 0.031517 3 3.05

REPRODUCIBILITY - APPRAISAR VARIATION (AV)

X Diff = 0.012 % AV = 100[AV/TV]

K2 = 2.70

= 68%

AV = SQRT OF [(X Diff X K2) - (EV / n x r) ]

= 0.032

Note: n = number of parts; r = no. of trials

2 3

3.65 2.70

REPRODUCIBILITY & REPEATABILITY (R&R)

%R&R = 100[R&R/TV]

R&R = SQRT OF ( EV + AV )

= 0.045 = 96%

PART VARIATION (PV) Parts (n) K 3

2 3.65 % PV = 100[PV/TV]

Rp = 0.008 3 2.70

K3 = 1.62 4 2.30 = 27%

5 2.08

PV = Rp X K3 6 1.93

= 0.0126 7 1.82

8 1.74

9 1.67

10 1.62

TOTAL VARIATION (TV)

TV = SQRT OF (R&R + PV )

= 0.0466

PERFORMED BY : DATE :

MEASUREMENT UNIT ANALYSIS % PROCESS VARIATION

No. of Operators

K 2

From Data Sheet:

0.0103 X diff 0.012 Rp 0.008

Specification 0.6 ~ 1.0mm

Characteristic Gauge Type

Operator Name (s)

Part Name Gauge Name

Part No. Gauge No.

No. of operators No. of Parts

GAUGE REPEATABILITY AND REPRODUCIBILITY ANALYSIS REPORT

Rev. No. Approved Checked

22

22

2 2

18](https://image.slidesharecdn.com/msatraining-191018130659/85/Msa-training-18-320.jpg)