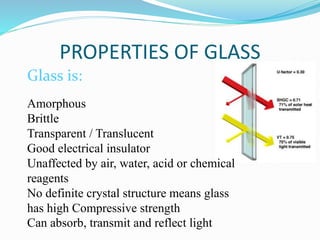

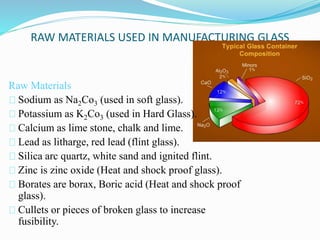

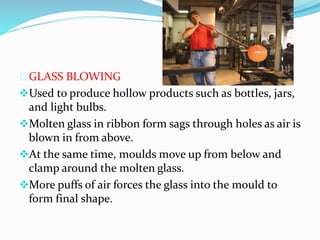

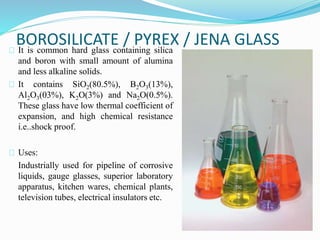

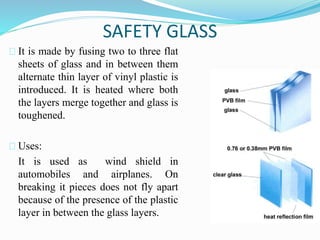

Glass is an amorphous solid made by rapidly cooling molten materials such as silica, soda ash, limestone, and lead. It has no definite melting point and softens over a range of temperatures. Glass is produced through melting and refining raw materials, forming the molten glass through various techniques like pressing or blowing, heat treating for strength and annealing, and finishing the surface. The main types of glass are soda-lime glass which is low-cost but not acid resistant, lead glass which has high refractive index, and borosilicate glass which is heat and chemically resistant. Recent developments include bioactive glass for bone repair and replacement.