The document discusses process capability and defines key terms related to process capability. It provides the standard formula for process capability using 6 sigma and explains how process capability is compared to specification limits. It then discusses different process capability indices including Cp, Cpk, and Cpm. It explains how these indices measure both potential and actual process capability. The document also discusses limitations of the Cp index and the use of Cpk to address process centering. It describes how to calculate confidence intervals for process capability ratios and discusses some key process performance metrics.

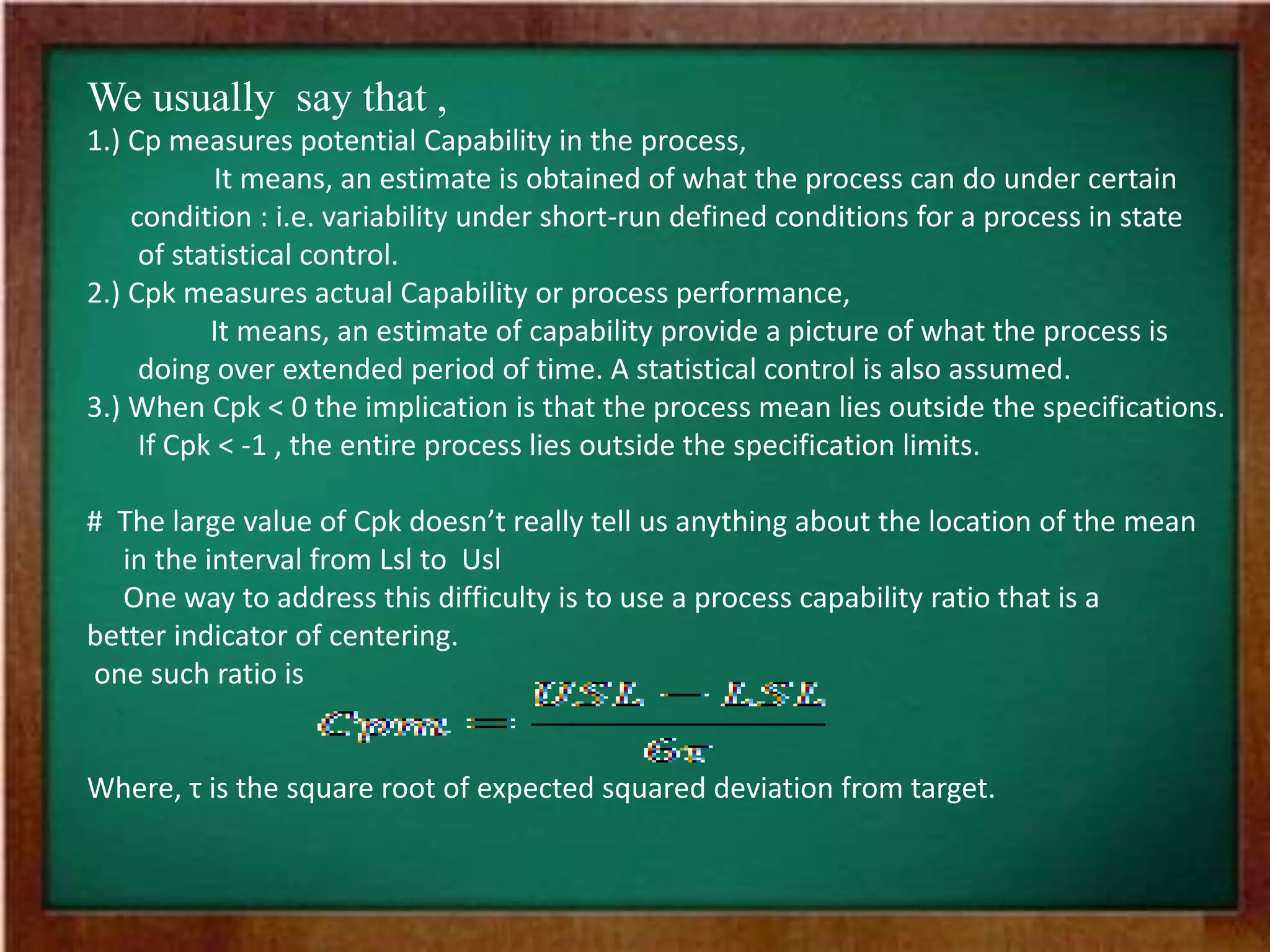

![Limitation of Cp Index & To Generate Cpk

The Cp index is limited in its use since it doesn’t address the centering of the process

Relative to he specification limit. For that reason ,the Cpk was developed and

I is defind as

Cpk = min[ Cpku,Cpkl]

Where, Cpku= =Upper Process Capability Index

Cpkl= =Lower Process Capability Index

If Cp = Cpk the process is center at the midpoint of the specifications.

Cpk <Cp the process is off center. The magnitude of Cpk relative to Cp is a direct

measure of how off-centre the process is operating.](https://image.slidesharecdn.com/1890c7cf-146d-4e07-abab-a3b540aceae7-151011161559-lva1-app6892/75/PROCESS-CAPABILITY-9-2048.jpg)

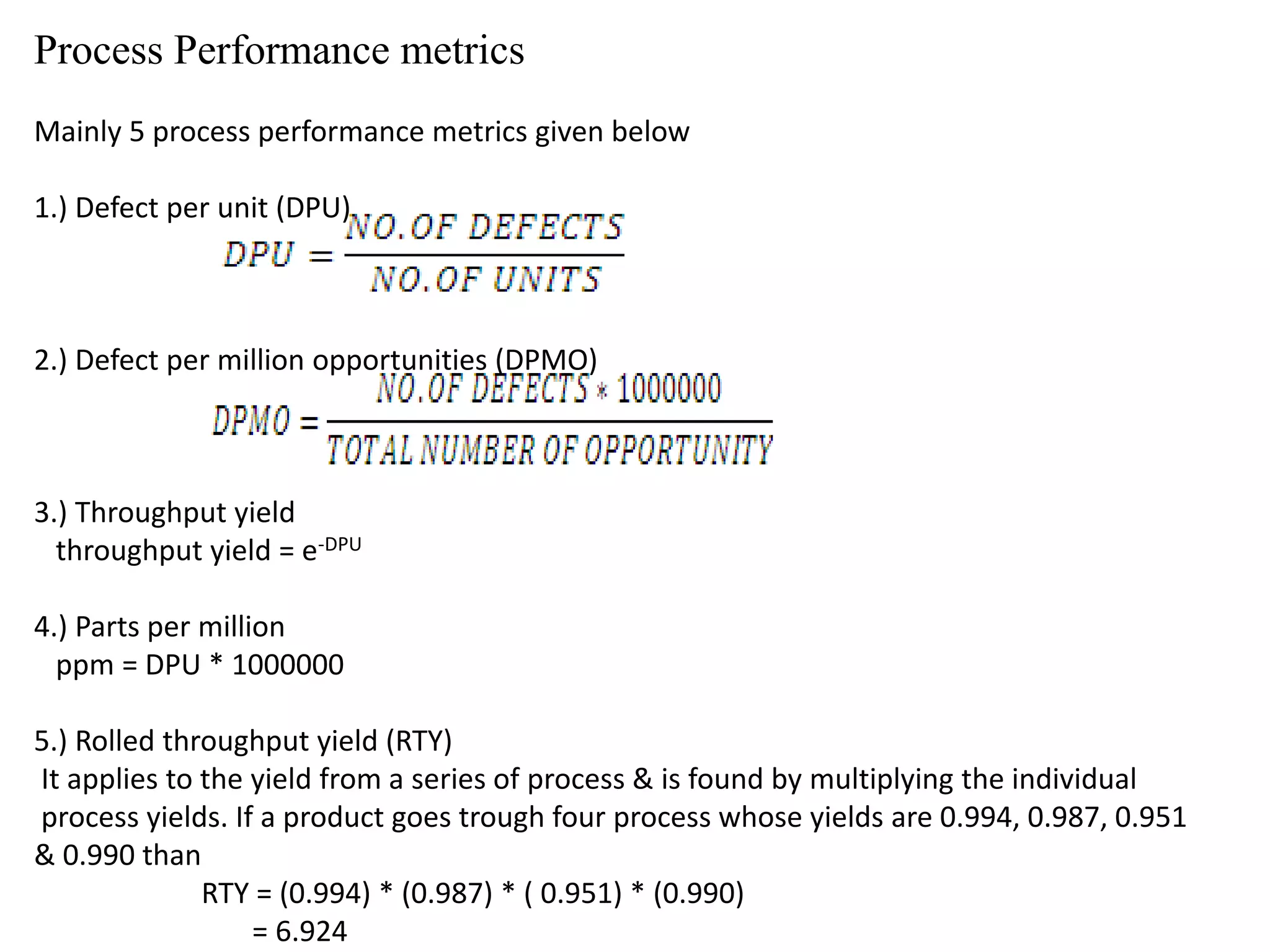

![Cpm

• You are almost never going to use

this, but for completeness…..

• In some processes you will not

target the center point.

• Example cutting impellers you

want to cut an impeller diameter

between 196 and 200 mm

• It may be cheaper to bias the

target cut towards say 199mm

instead of 198mm

• So in this case if we target

199mm we want to measure

the process against the target

instead of the center point

Cpm = Cp/[1+((Xbar-T)^2/s^2)]; Where T is the

target value. Explained above.](https://image.slidesharecdn.com/1890c7cf-146d-4e07-abab-a3b540aceae7-151011161559-lva1-app6892/75/PROCESS-CAPABILITY-15-2048.jpg)