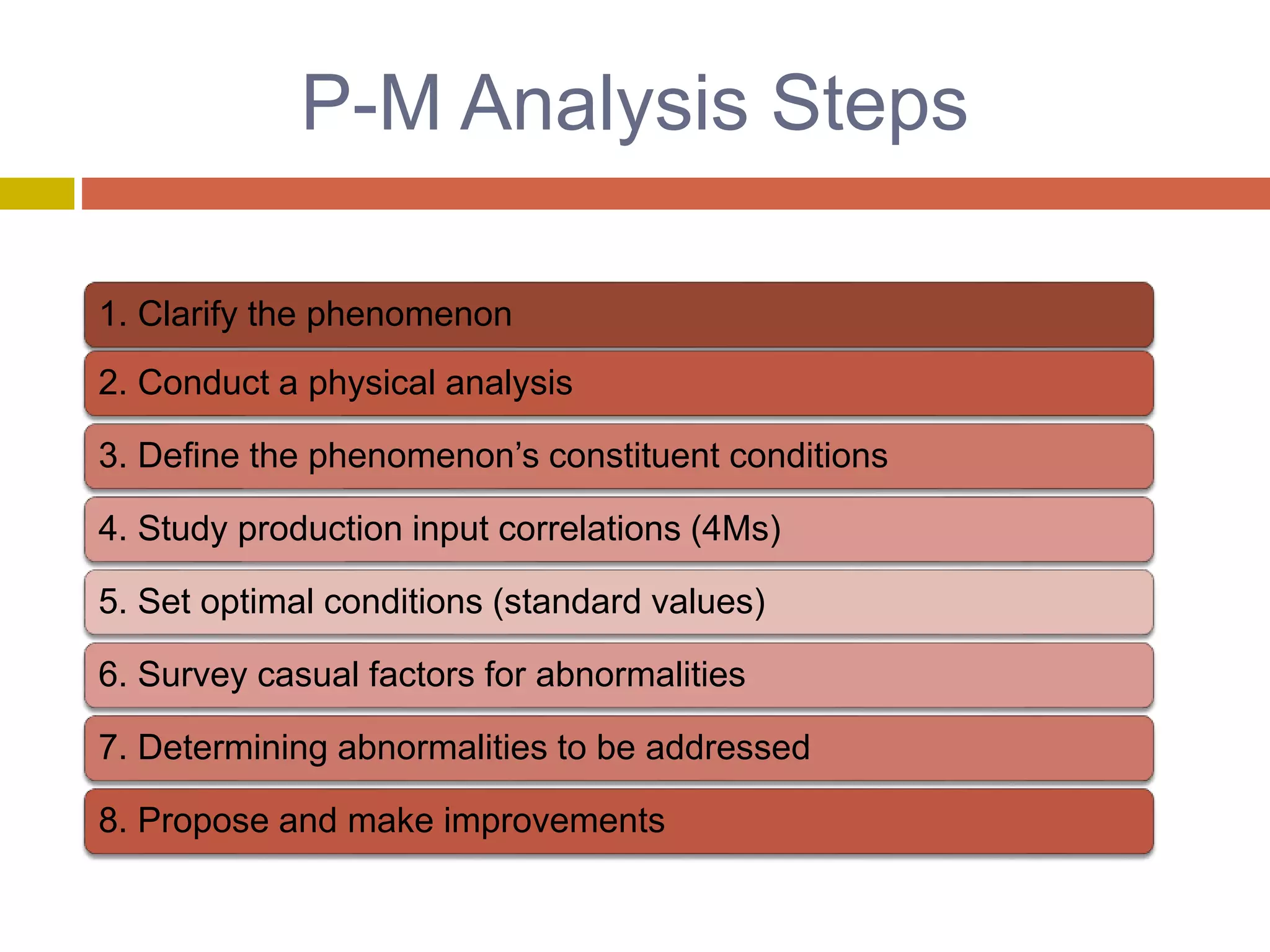

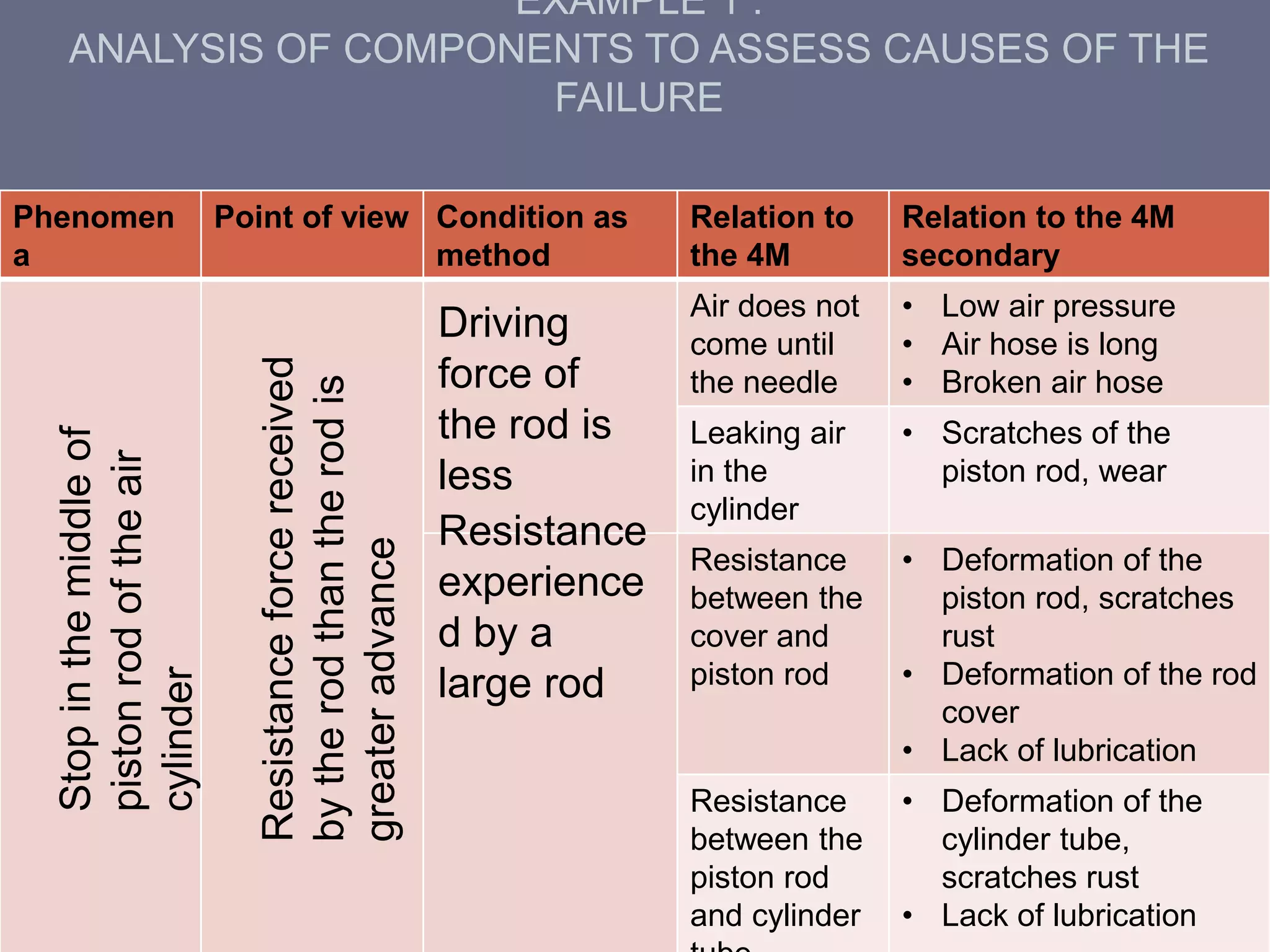

This document discusses maintenance management and phenomenon and mechanism analysis, specifically P-M analysis. P-M analysis was developed in Japan as a way to physically analyze chronic losses and their underlying causes. It involves 8 steps: 1) clarifying the phenomenon, 2) conducting a physical analysis, 3) defining constituent conditions, 4) studying correlations with production inputs, 5) establishing optimal conditions, 6) surveying causal factors, 7) determining abnormalities, and 8) proposing improvements. The document provides examples of using P-M analysis to identify abnormalities that cause failures in machines. It also discusses factors that could cause P-M analysis to be unsuccessful if not properly implemented.