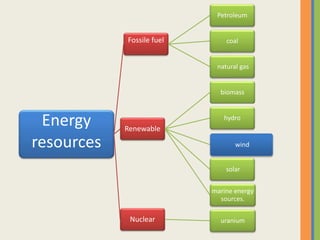

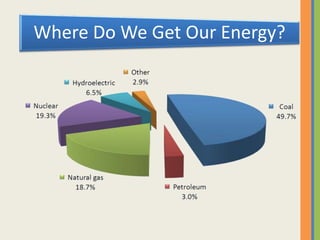

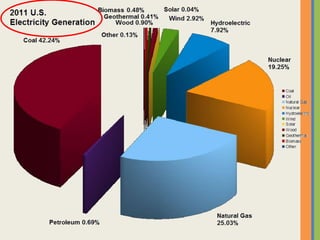

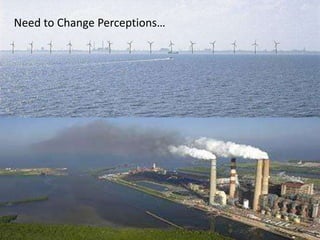

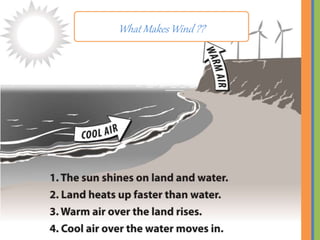

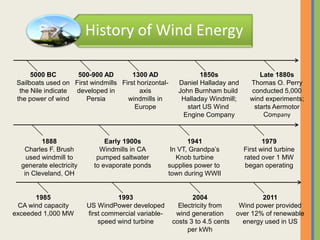

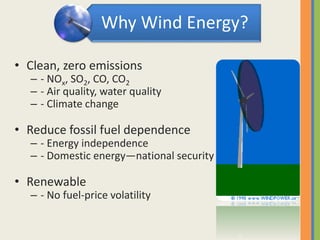

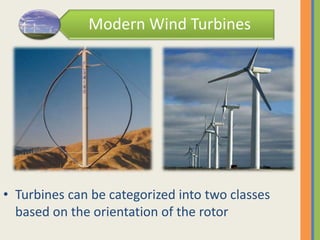

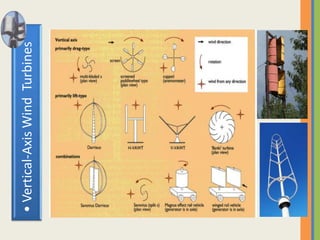

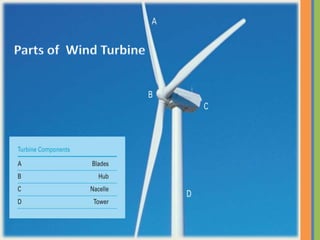

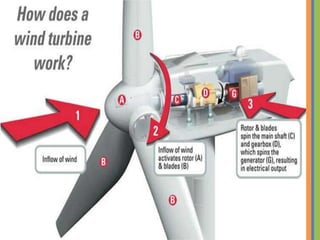

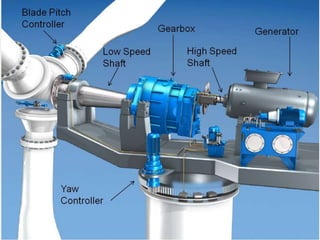

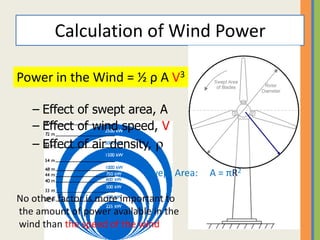

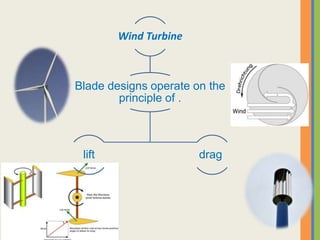

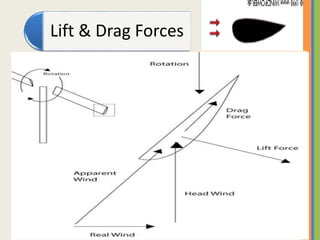

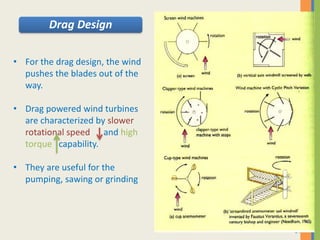

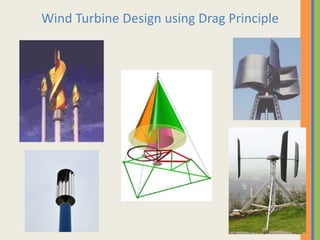

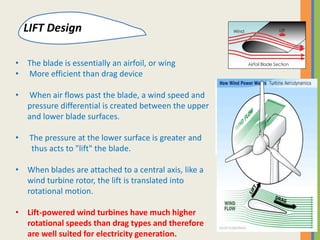

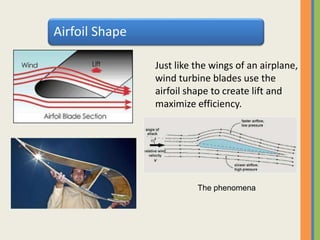

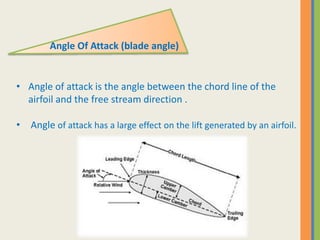

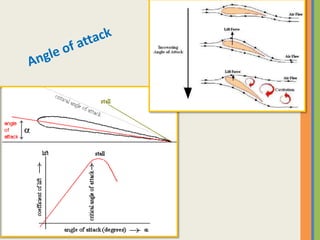

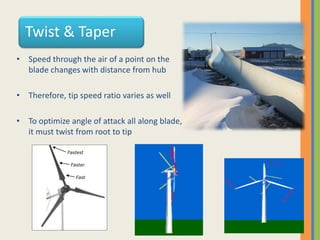

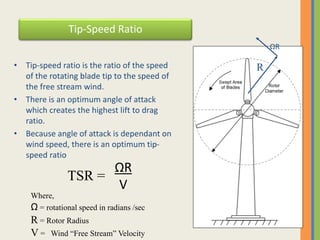

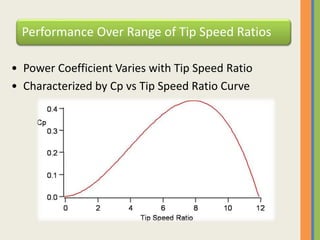

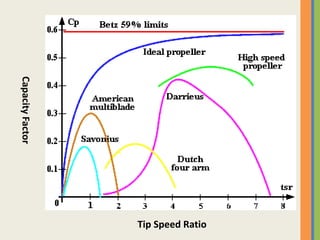

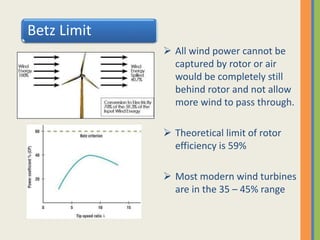

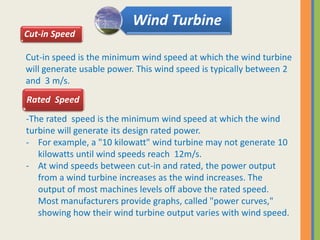

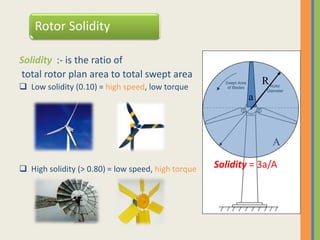

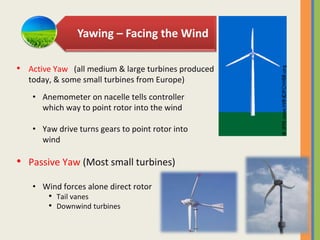

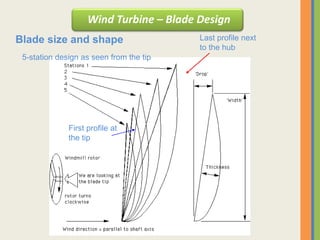

The document discusses various aspects of wind energy and wind turbines. It begins by noting that energy plays a vital role in our lives and discusses different energy resources including fossil fuels and renewable sources like wind. It then provides details on the history of wind energy use dating back thousands of years, as well as modern wind turbine design and components. The document discusses how wind turbines work, including blade design principles, optimal tip speed ratios, and cut-in, rated, and cut-out wind speeds. It also addresses wind farm installation and the advantages of wind power as a renewable and non-polluting energy source.