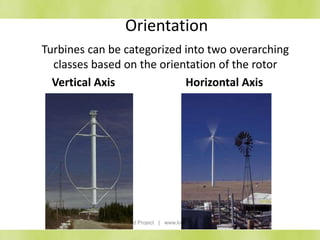

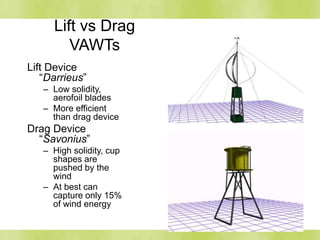

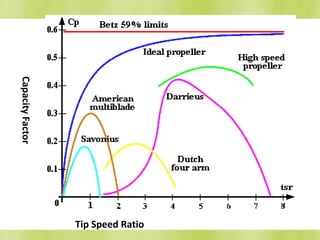

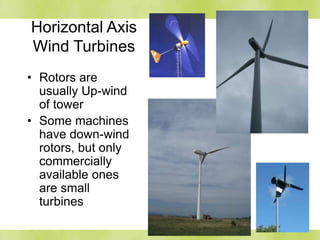

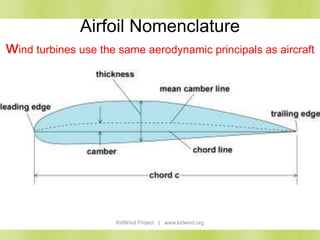

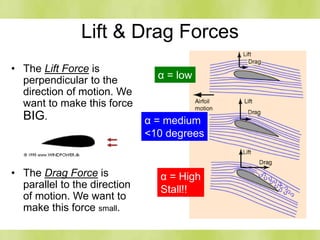

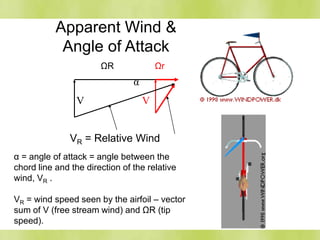

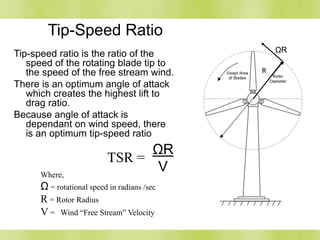

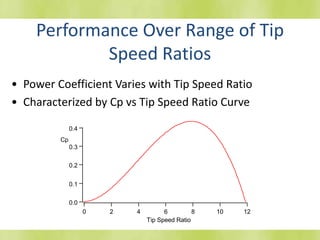

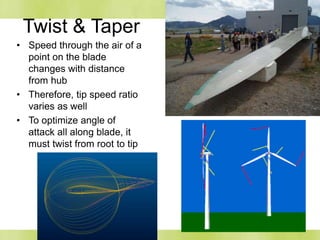

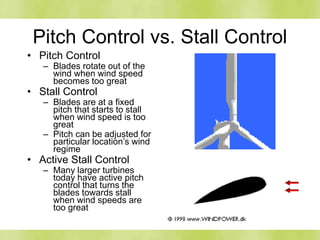

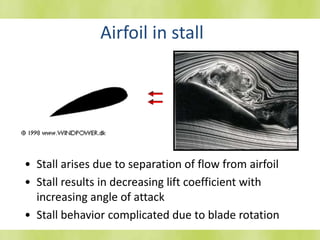

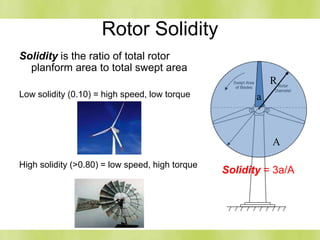

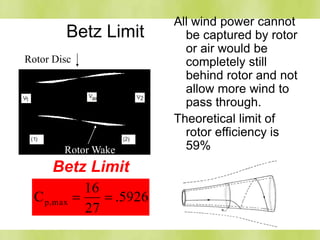

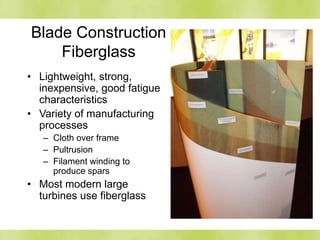

The document discusses wind energy technology and what designs work best. It summarizes that horizontal axis wind turbines are generally more successful than vertical axis designs. Key factors that determine turbine performance are discussed, such as airfoil shape, tip speed ratio, rotor solidity, and controls like variable pitch and stall regulation. Common materials used for blades like wood, metal, and fiberglass composites are also outlined. The goal of the KidWind project is to introduce wind power concepts to students through hands-on science activities.