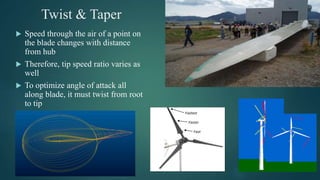

This document provides an overview of wind energy fundamentals and design considerations for wind turbines. It discusses how wind power depends on air volume, velocity, and density. It also explains power coefficients and the Betz limit for wind turbine efficiency. The two main types of wind turbines - horizontal axis and vertical axis - are described. Key design considerations for wind turbines include the number of blades, blade composition and construction, and factors that influence turbine performance like airfoil shape, twist, taper, tip-speed ratio, and rotor solidity.