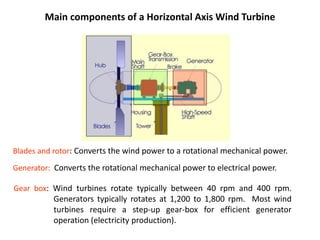

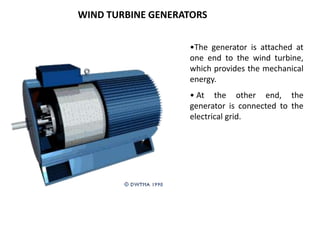

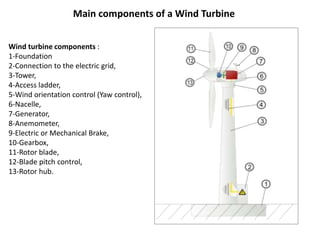

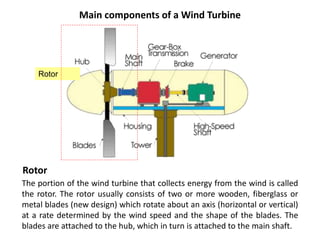

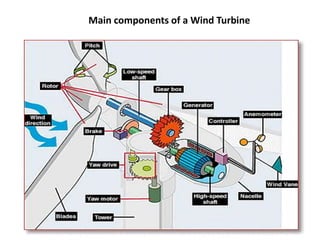

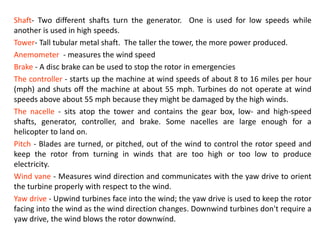

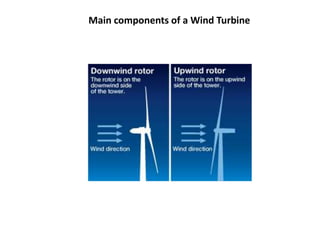

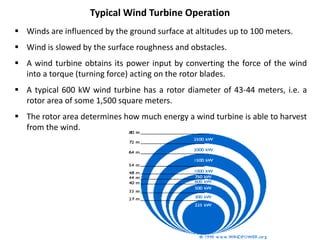

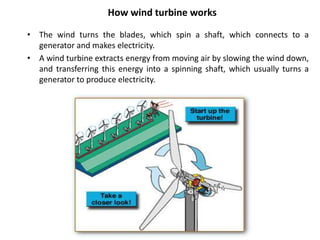

Wind power works by using wind turbines to harness the kinetic energy of the wind. Wind turbines capture wind energy through their rotor blades and convert it into mechanical rotation to spin a generator that produces electricity. Key components of a wind turbine include the blades, shaft, gearbox, generator, and tower. As wind speed increases, power output also increases up to the turbine's rated capacity, after which the turbine's design limits further power production. Larger turbines with taller towers and wider rotors can generate more electricity. Advantages of wind power are that it is a renewable domestic source of energy generation with no pollution.