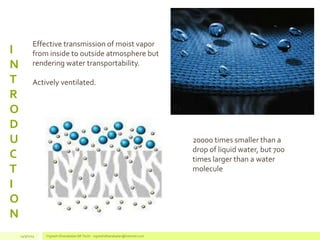

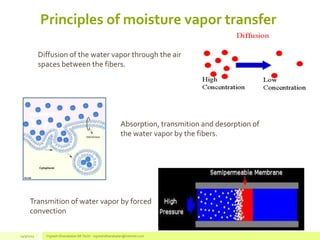

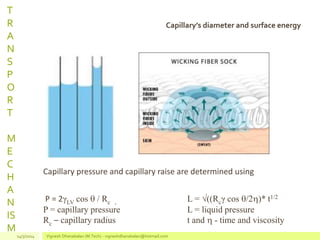

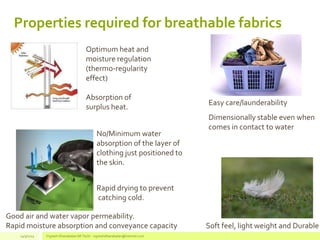

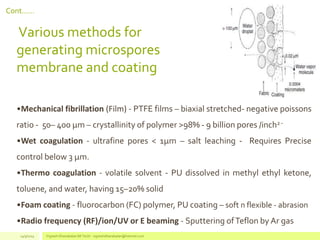

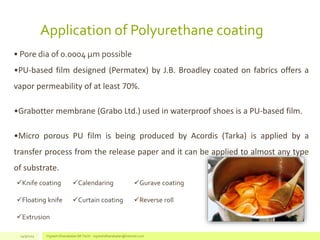

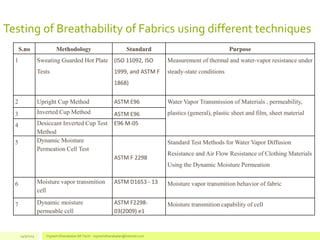

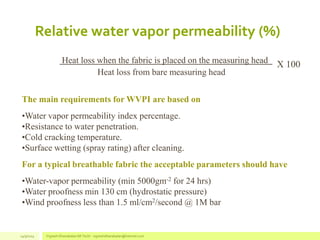

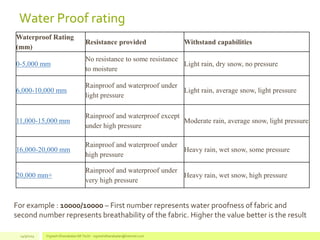

The document discusses waterproof breathable fabrics, detailing the principles of moisture vapor transfer and the properties required for effective breathable textiles, such as softness and rapid drying. It outlines various technologies for manufacturing these fabrics, including techniques for creating micro porous membranes and polymer coatings. Additionally, it highlights testing methods and key performance parameters for assessing breathability and waterproof ratings.