Agrotextiles are textiles manufactured for agricultural applications such as agriculture, horticulture, and animal husbandry. They are used to control the environment for plants and animals. Recent developments in agrotextiles include polymer fibre balls as a soil substitute, screening fabrics for sunlight management, knitted net hoses for water transportation, superabsorbent polymer fibre mats for water management, and composites of hemp or polypropylene for reducing soil pollutants. For agrotextile products to be effective, they require properties such as resistance to solar radiation, weather, ultraviolet radiation, the ability to retain water, biodegradability, light weight, and resistance to microorganisms.

![Use of water retention nets coated with Superabsorbent polymer resin

Textile structures coated with SAP resin, enhance water retention property to support plant growth

Water-absorbing polymers, which are classified as hydrogels when mixed, absorb aqueous solutions

through hydrogen bonding with water molecules. A SAP's ability to absorb water depends on the ionic

concentration of the aqueous solution. In deionized and distilled water, an SAP may absorb 300 times its

weight from 30 to 60 times its own volume) and can become up to 99.9% liquid, but when put into a

0.9% saline solution, the absorbency drops to approximately 50 times its weight.[citation needed] The

presence of valence cations in the solution impedes the polymer's ability to bond with the water

molecule. The total absorbency and swelling capacity are controlled by the type and degree of cross-

linkers used to make the gel. Low-density cross-linked SAPs generally have a higher absorbent capacity

and swell to a larger degree. These types of SAPs also have a softer and stickier gel formation. High

cross-link density polymers exhibit lower absorbent capacity and swell, but the gel strength is firmer and

can maintain particle shape even under modest pressure.

Composites of hemp or polypropylene for reducing soil pollutants

Composite of Hemp or Polypropylene nonwoven fabrics and aluminium silicate, found to be useful in

protection of soil from chemical pollutants Natural fibers as reinforced materials in polymer composites

have attracted much attention for being applicable in many fields such as automotive, aerospace,

packaging, construction, and transportation industries . Natural fibers which are used as fillers or

reinforcement materials in polymer composites including palm sheath , palm leaf , guayule biomass,

bagasse, sunflower stalk flour , banana, sugarcane, pineapple, ramie, and cotton [13] show many

advantages such as renewability, biodegradability, CO2 neutrality, nontoxicity, wide availability, low

cost, low density, low energy consumption during fabrication, and high specific strength compared to

synthetic fibers . Therefore, the polymer composites reinforced by natural fibers are becoming

significantly important for the production of a large variety of composites due to being relatively cheap,

lightweight, and eco-friendly materials .

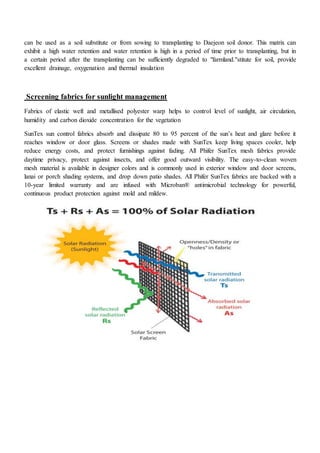

Development of reflective Agrotextiles for Sun management

Many crops are also extremely light sensitive. Sunlight management is the process of manipulating the

sunlight quality and quantity to which plants are exposed. A new generation of agrotextiles can be

developed to address this problem. They would allow the grower to choose both the duration of light as

well as the particular wavelength that will produce the desired effect from the plants at all stages of

development. The proposed project aims to develop wide range of agrotextile screens which will reflect

light and thus ripen all plants uniformly protecting them from extreme climatic conditions. It is proposed

to develop woven reflective agro ground covers with suitable reflective coatings leading to desired

results.](https://image.slidesharecdn.com/recentdevelopmentinagrotextile-191019182339/85/Recent-development-in-Agrotextiles-5-320.jpg)