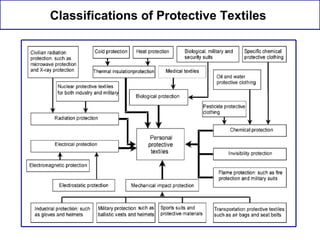

This document discusses various types of protective textiles, including materials and classifications. It focuses on chemical protective clothing. Key points:

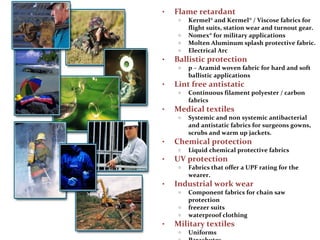

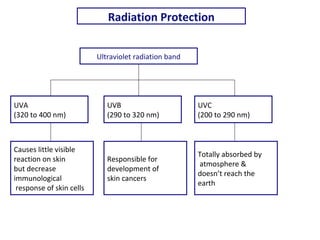

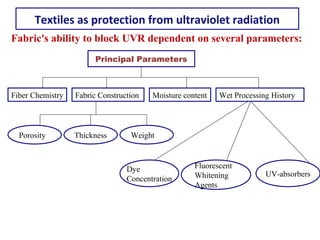

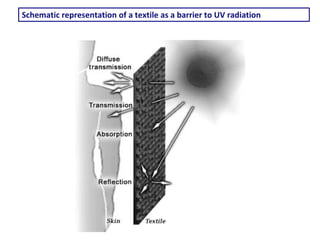

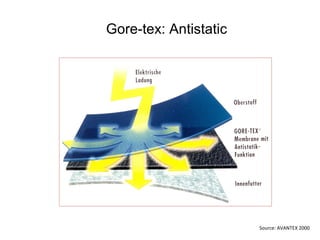

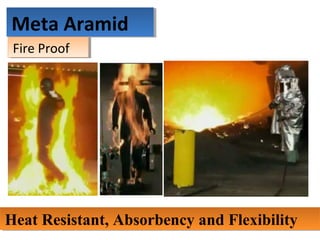

- Protective textiles are designed to protect the wearer from environmental hazards and include flame retardant, ballistic protection, medical, chemical, UV protection and industrial work wear fabrics.

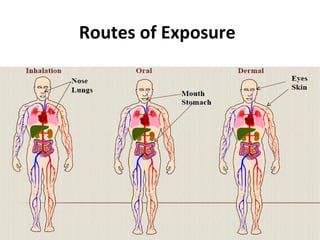

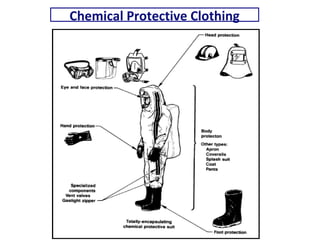

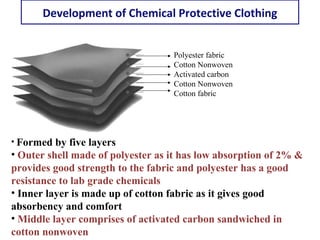

- Chemical protective clothing must resist permeation, degradation and penetration from chemicals. Important considerations in design are breakthrough time and liquid repellency.

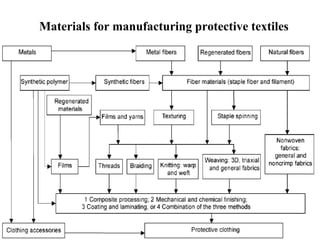

- Common materials for chemical protection include nonwoven fabrics like Tyvek and SMS polypropylene, activated carbon, and multi-layer combinations of fabrics and nonwovens.

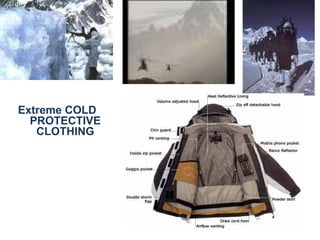

- Extreme cold protective clothing uses durable, flexible and insulating