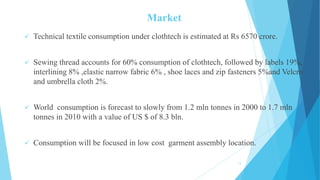

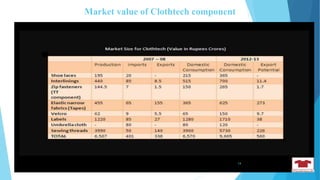

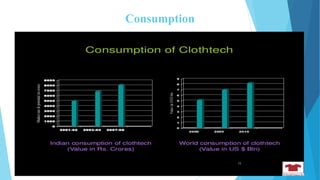

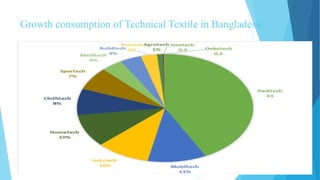

This presentation discusses clothtech, a category of technical textiles used in apparel and footwear manufacturing. Clothtech includes materials like interlinings, shoe fabrics, elastic fabrics, and lining fabrics that are further processed and bonded using thermoplastic powders. Common applications include components of shoes like shoe laces and interlinings, as well as sewing threads, zippers, velcro, labels, and umbrella cloth for clothing. Properties required for clothtech include stability at high temperatures and pressures, abrasion resistance, durability, and solvent resistance. The global market for clothtech is estimated to be around $8.3 billion and consumption is expected to grow slowly between 2000-2010, focused in low-cost app