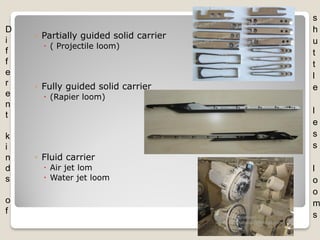

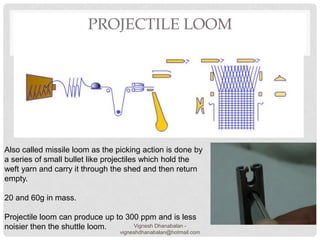

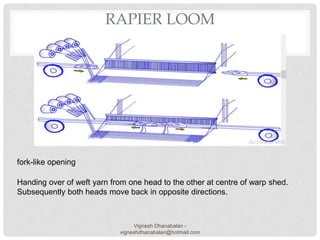

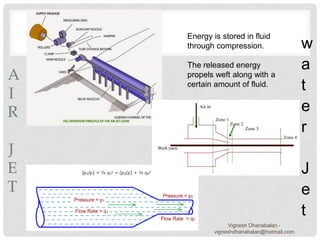

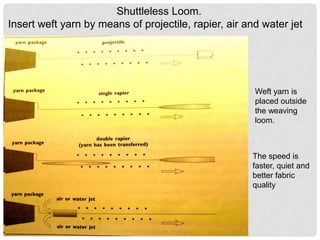

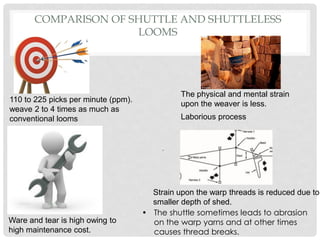

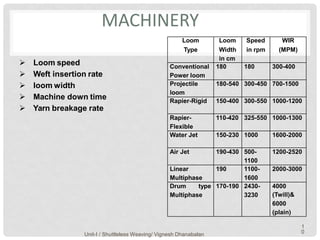

This document discusses different types of shuttleless looms. It classifies shuttleless looms into three categories: partially guided solid carrier looms like projectile looms; fully guided solid carrier looms like rapier looms; and fluid carrier looms like air jet and water jet looms. Projectile looms use small projectiles to carry the weft yarn through the shed, rapier looms use fork-like rapiers, and fluid carrier looms use compressed air or water to propel the weft yarn. Shuttleless looms are faster, quieter, and produce better fabric quality than shuttle looms.