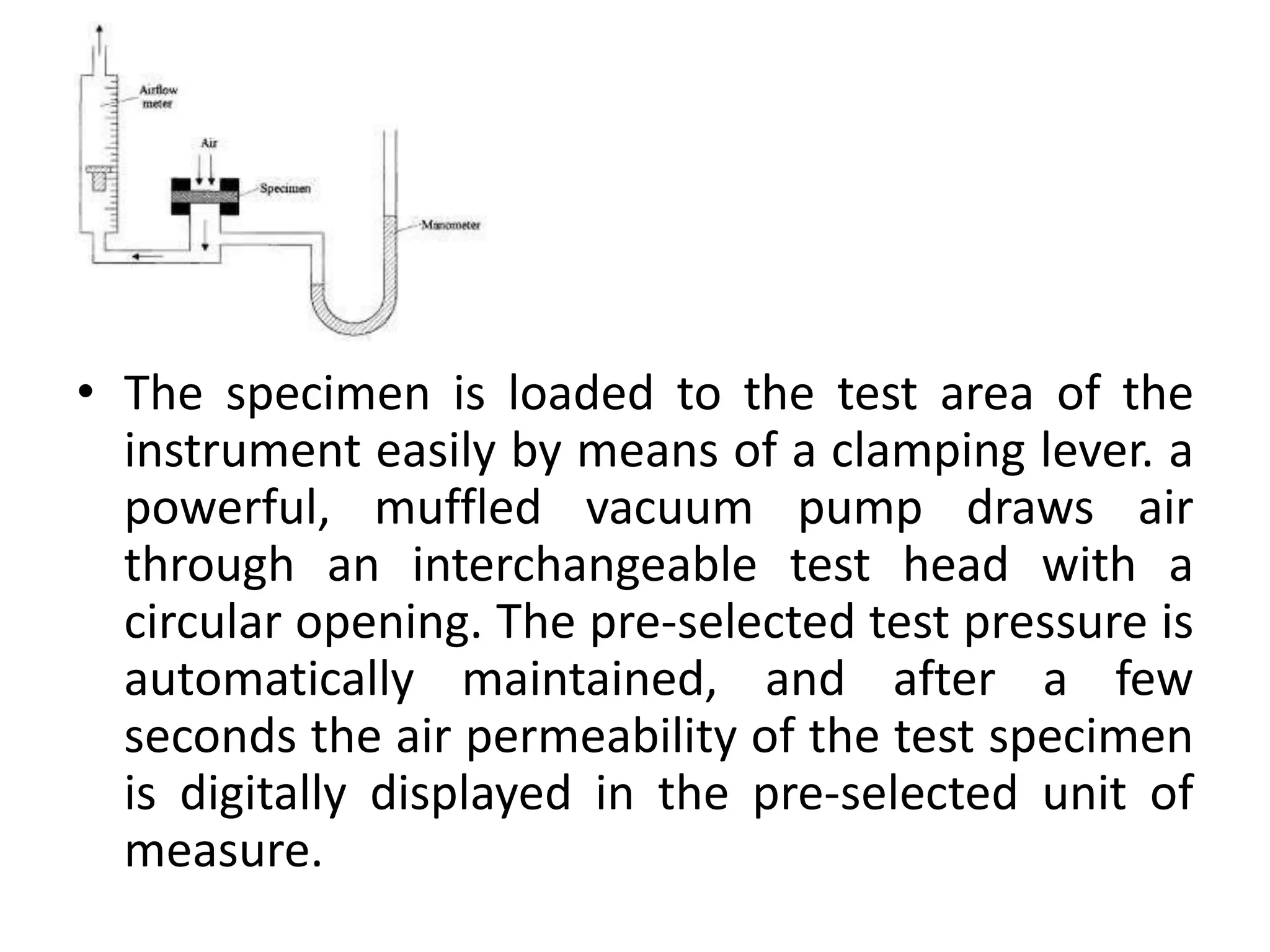

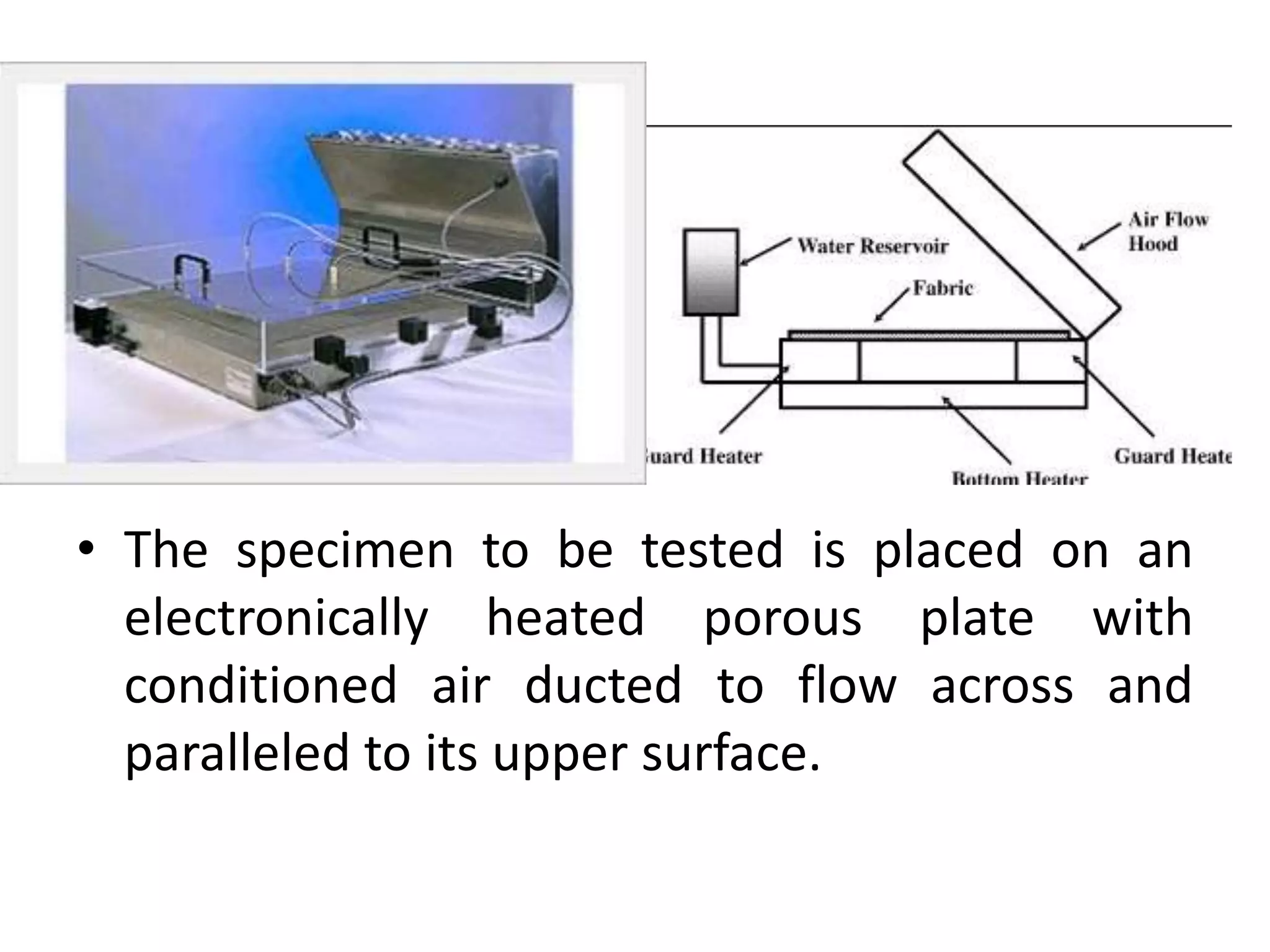

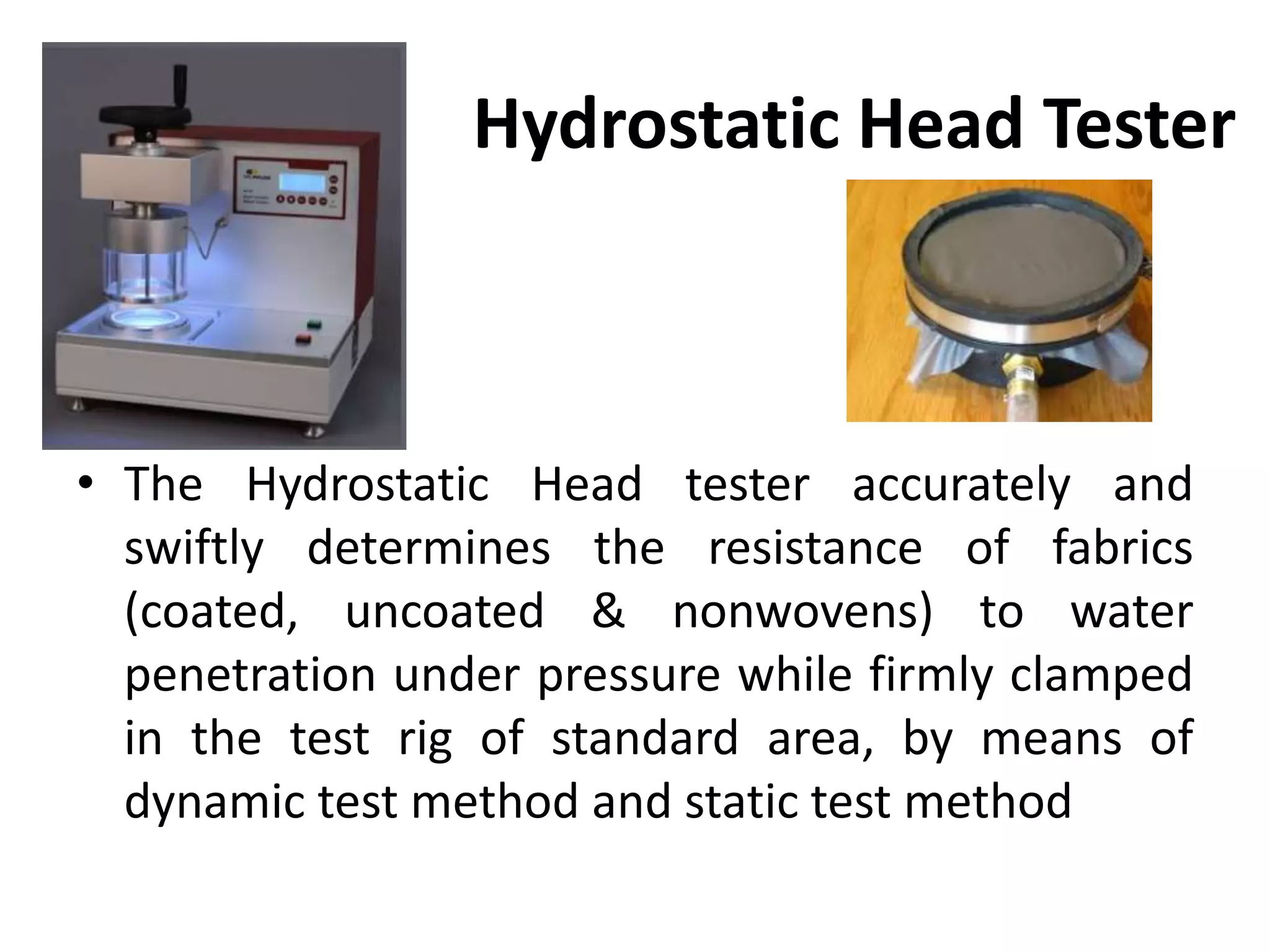

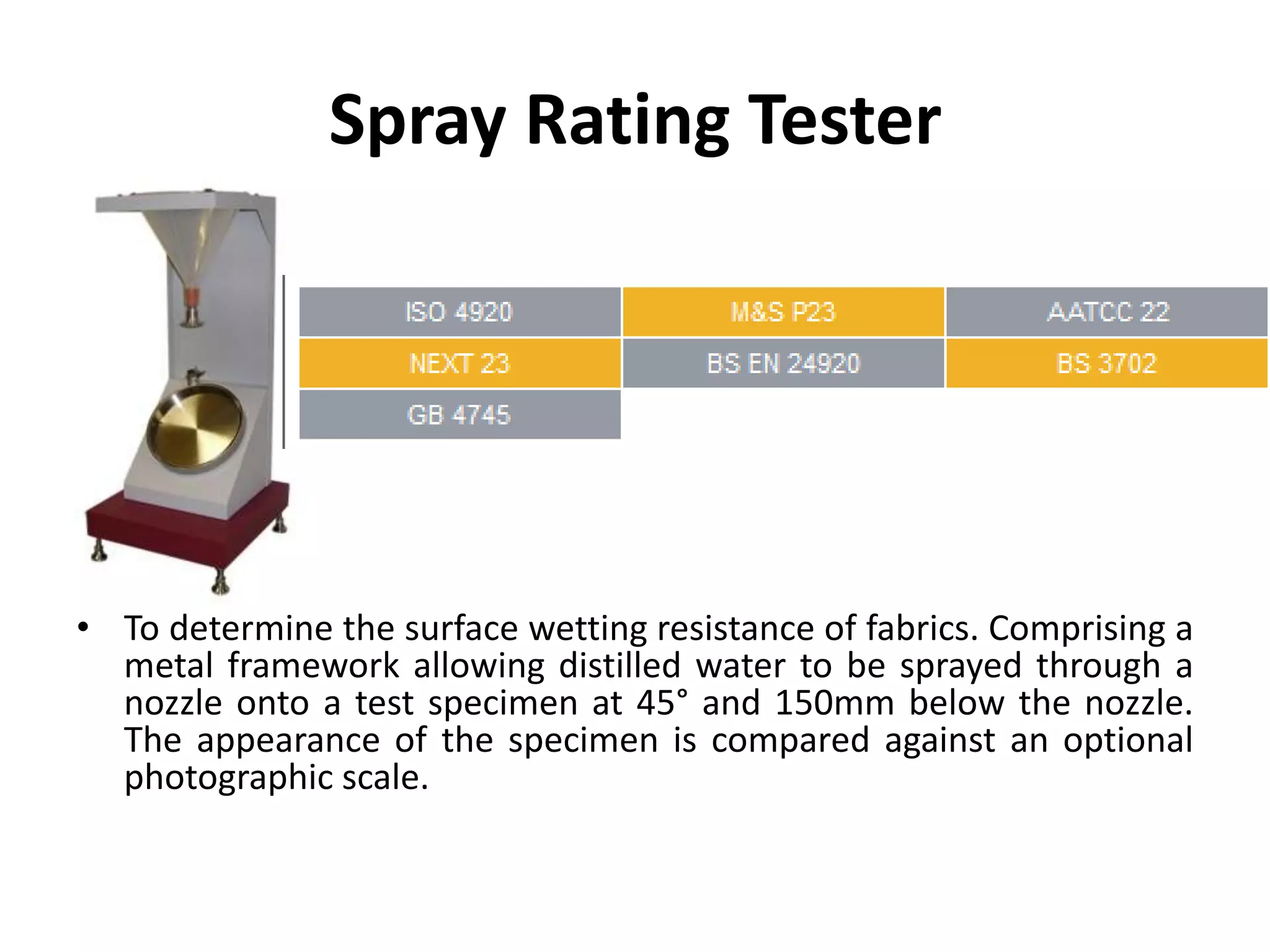

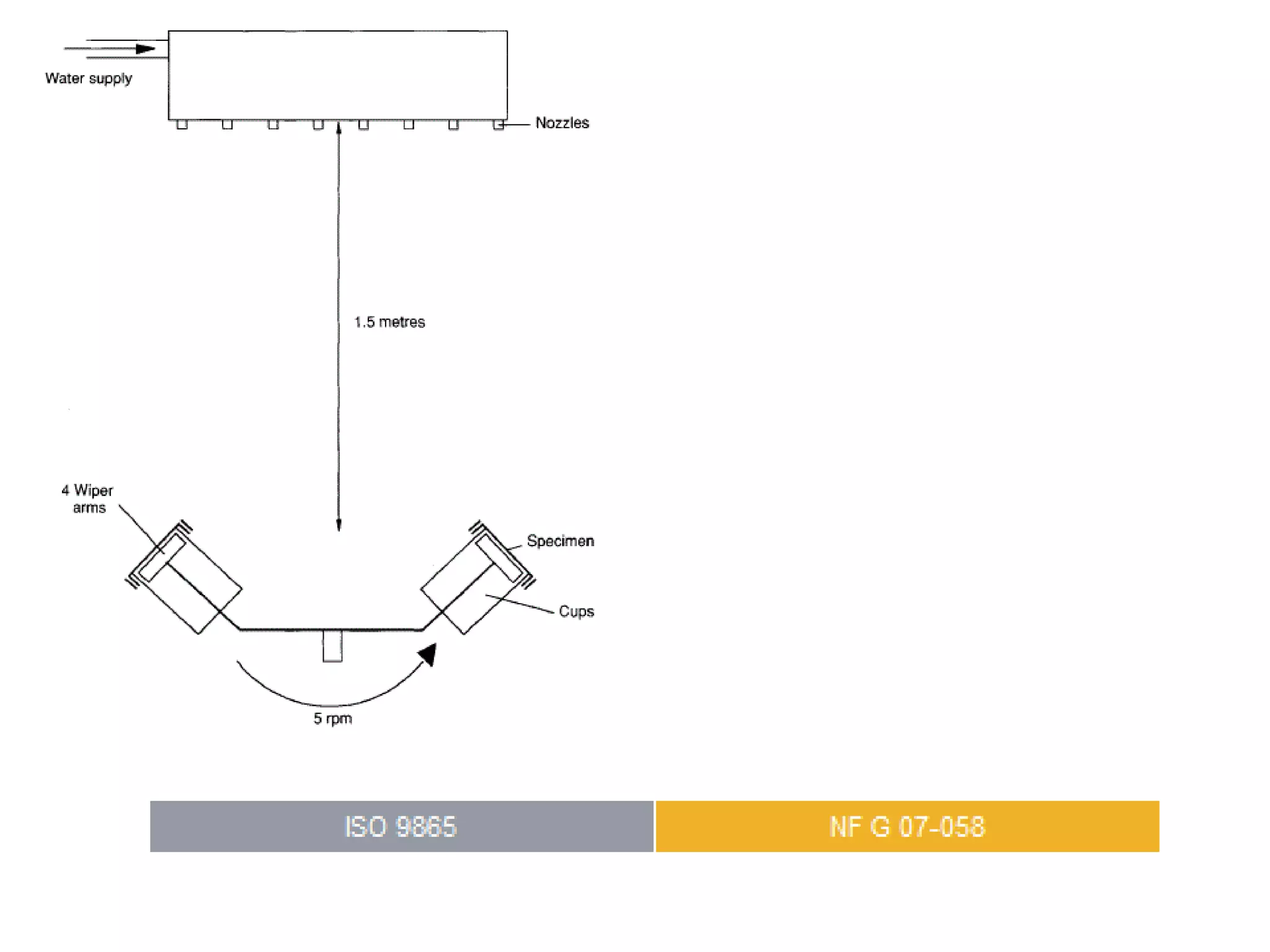

This document describes various testing equipment used to analyze the properties of textile fabrics, including moisture absorption, air permeability, water vapor permeability, moisture management, drying rate, stiffness, softness, heat and moisture transfer, water resistance, and rain resistance. Tests are performed to determine attributes important for breathability, comfort, and performance of fabrics.