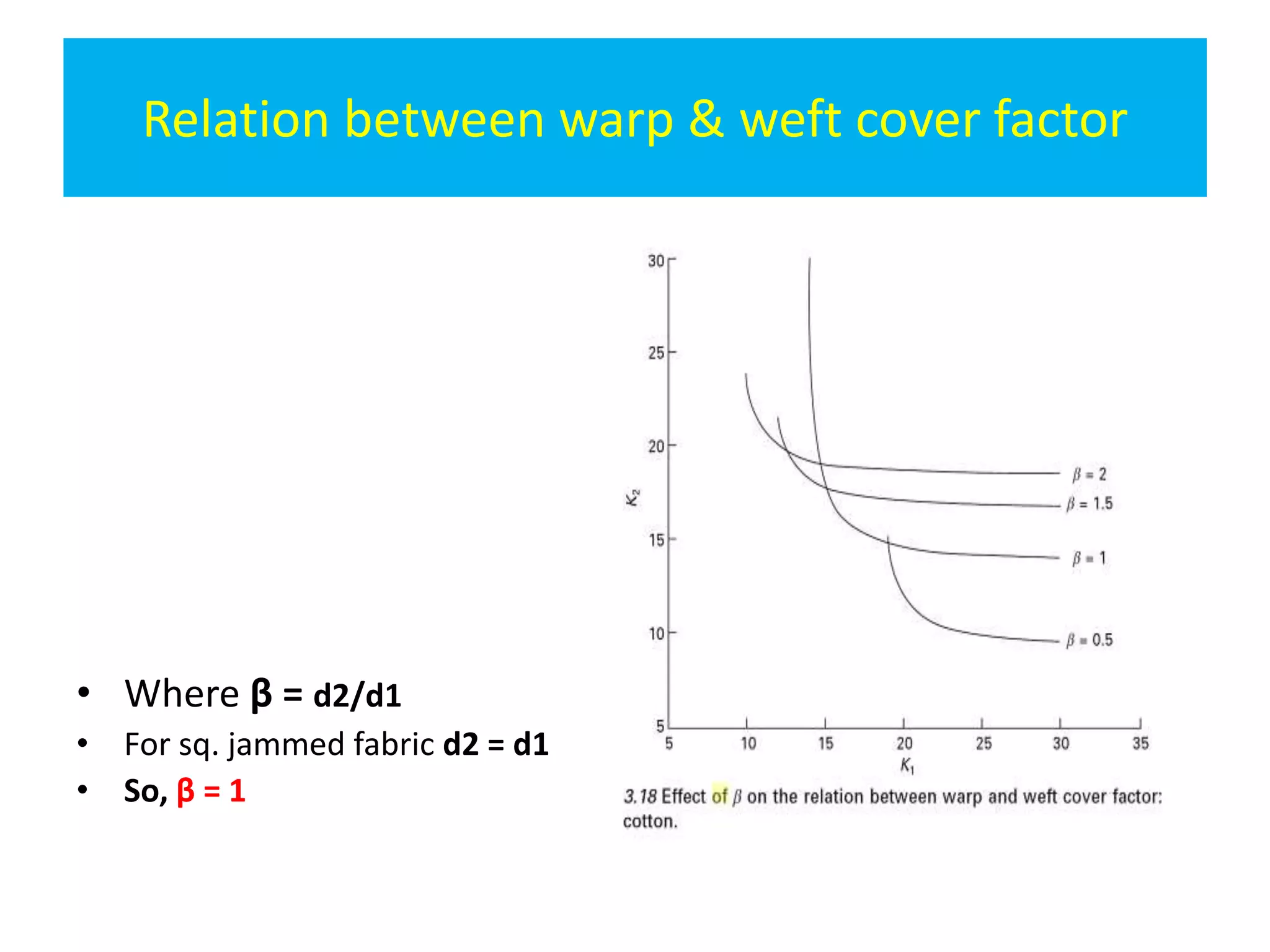

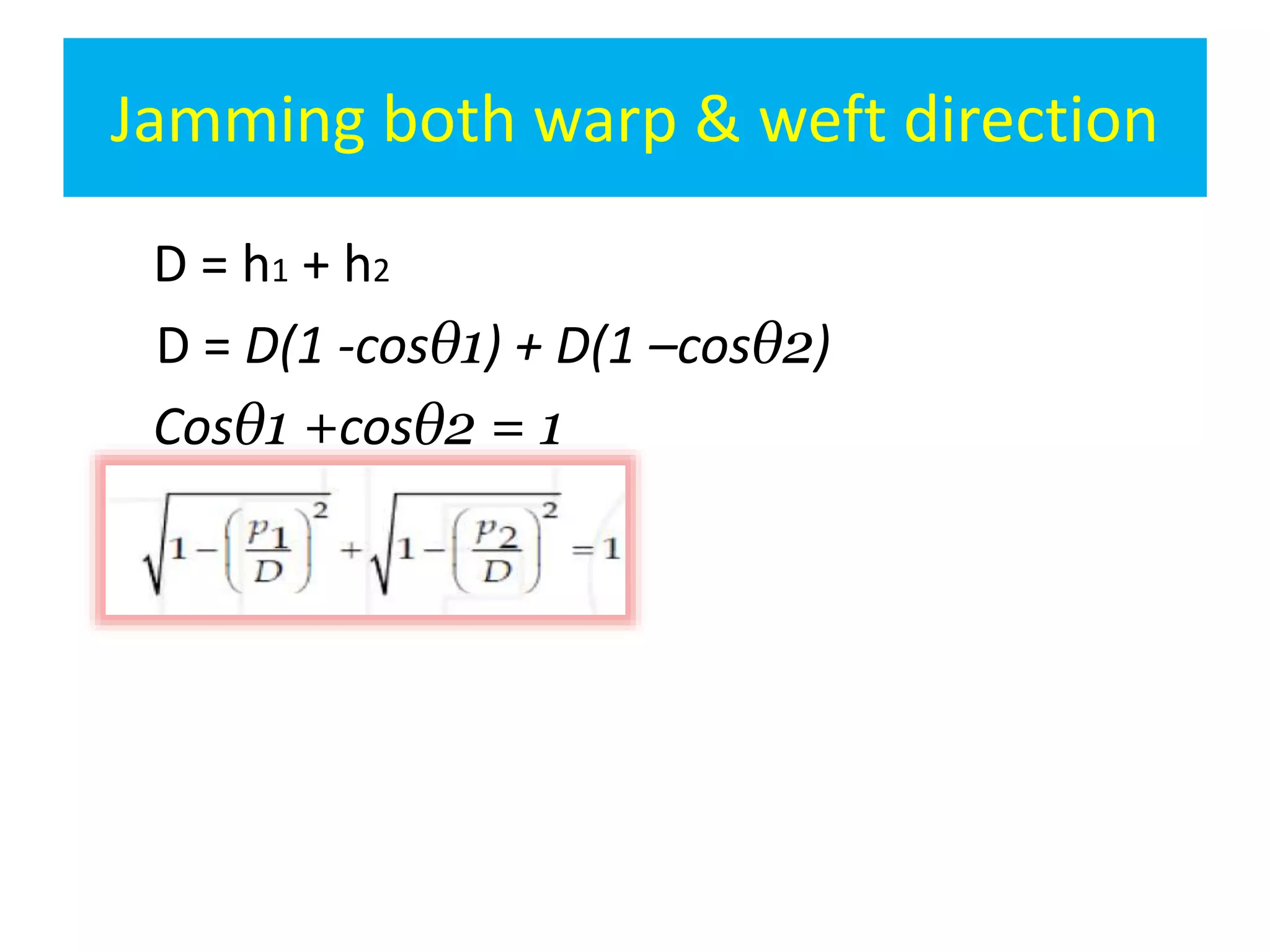

This document discusses jammed fabric structures and provides mathematical models to predict their properties. A jammed fabric is one where the warp and weft yarns are in intimate contact with no mobility between yarns. Pierce's model and the racetrack model are presented to calculate thread spacing, fabric cover, and crimp based on yarn diameters. A truly square jammed fabric has equal warp and weft spacing, crimp, and angles. Such a fabric has 20.9% crimp and cover factors of 16.2. Jammed fabrics are closely woven and used for waterproof, windproof and bulletproof applications.

![Crimp of sq. jammed fabric

• The crimp in fabric is the most important parameter which influences

several fabric properties such as extensibility , thickness , compressibility

and handle. It also decides quantity of yarn required to weave a fabric

during manufacturing.

The crimp of a sq. jammed fabric is about 20.9 %

we know,

Crimp (c) =l/p -1 [p=Dsinθ &l= Dθ ]

= Dθ/Dsinθ -1

= θ/sinθ – 1

= π/3/sin π/3 - 1 [θ = π/3]

=1.209 -1

= .209

So, c % = 20.9 %](https://image.slidesharecdn.com/sq-150531120015-lva1-app6892/75/Square-jammed-fabric-13-2048.jpg)