This document discusses different methods for waterproofing and water-repellent finishes on fabrics. It describes several techniques:

1. Applying a uniform coating of substances like rubber to block air and water passage through the fabric.

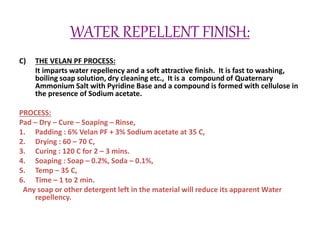

2. Using hydrophobic chemicals that are deposited on or make the fabric hydrophobic itself.

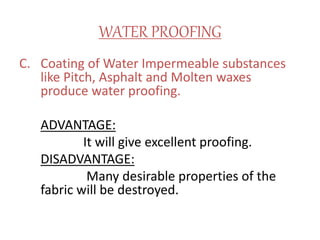

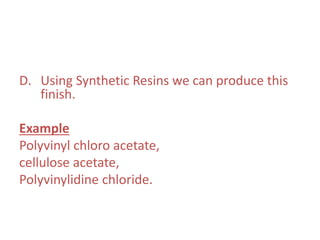

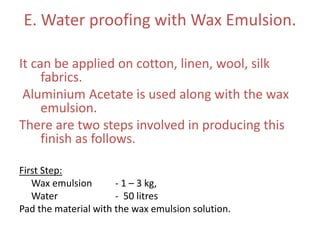

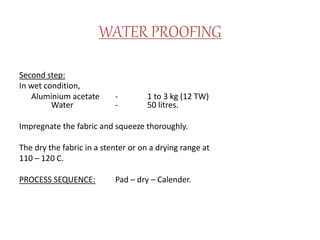

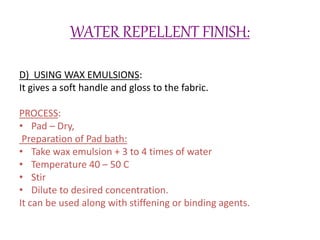

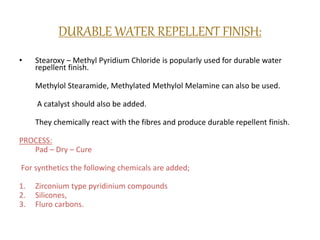

3. Specific techniques include coating with wax emulsions, synthetic resins, metallic salts, silicones and stearoxy methyl pyridium chloride.

4. The goal is to prevent air and water from passing through without making the fabric too stiff or altering its properties. Proper chemical selection and multi-step processes like padding, drying and curing are required.