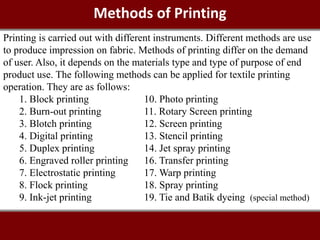

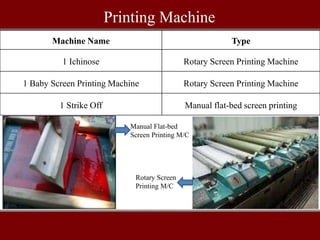

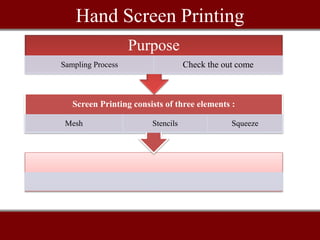

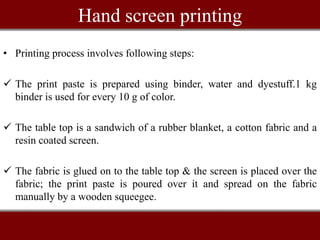

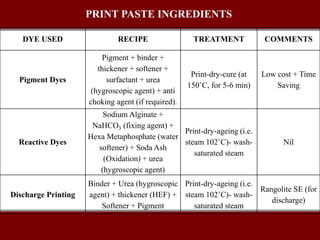

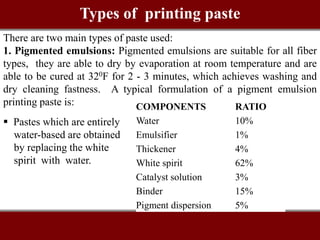

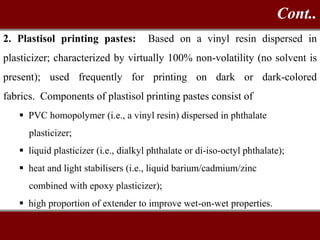

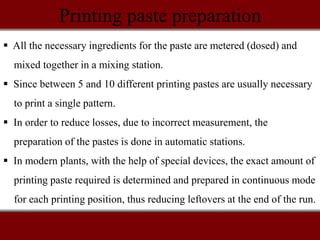

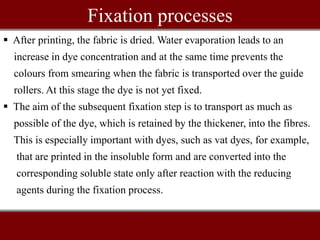

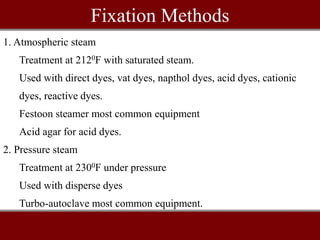

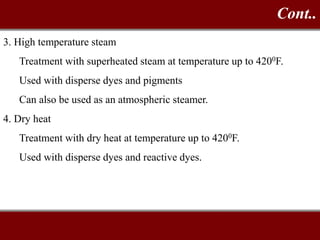

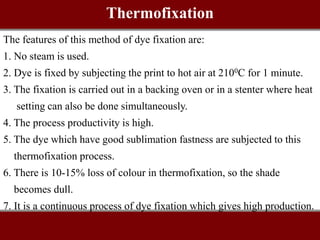

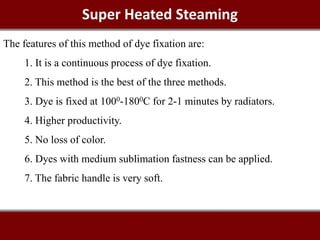

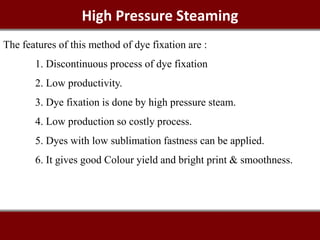

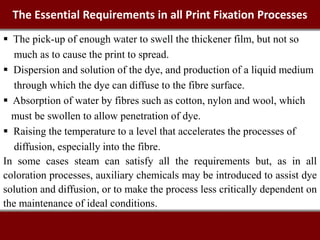

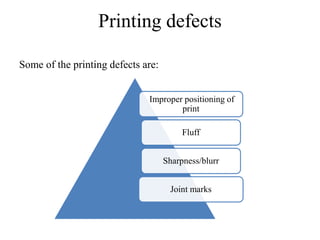

The document discusses textile printing, detailing various methods, styles, and the ingredients of printing paste, including preparation and fixation processes. It outlines four main types of printing: direct, mordant, resist, and discharge, and emphasizes the importance of machinery and human skills in achieving quality prints. Additionally, it covers the components of printing paste, the steps involved in the printing process, fixation methods, and potential printing defects.