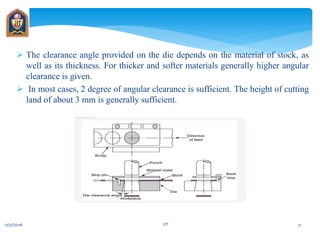

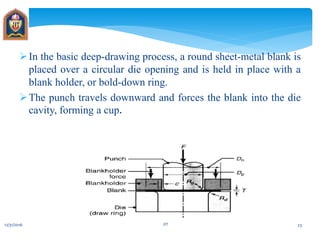

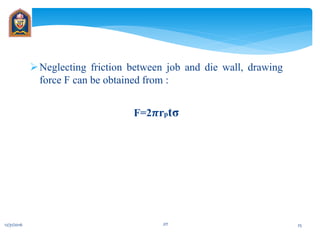

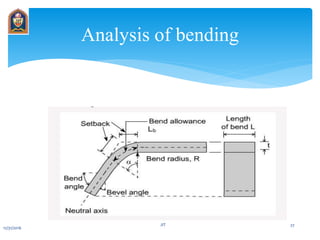

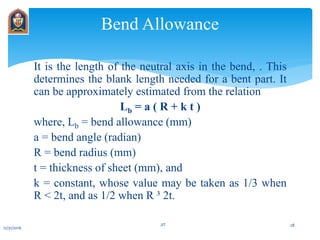

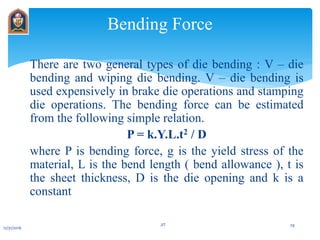

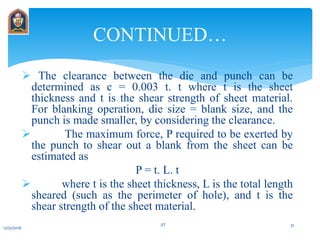

This document discusses sheet metal working processes. It begins by explaining that sheet metal forming dates back thousands of years and is used to make a wide variety of consumer and industrial products. The main sheet metal forming processes are stretching, bending, deep drawing, and press working. Press working shapes sheet metal using dies and punches without removing material. The document then goes into details about various sheet metal forming operations, tools, and calculations for processes like bending, deep drawing, blanking, and punching.