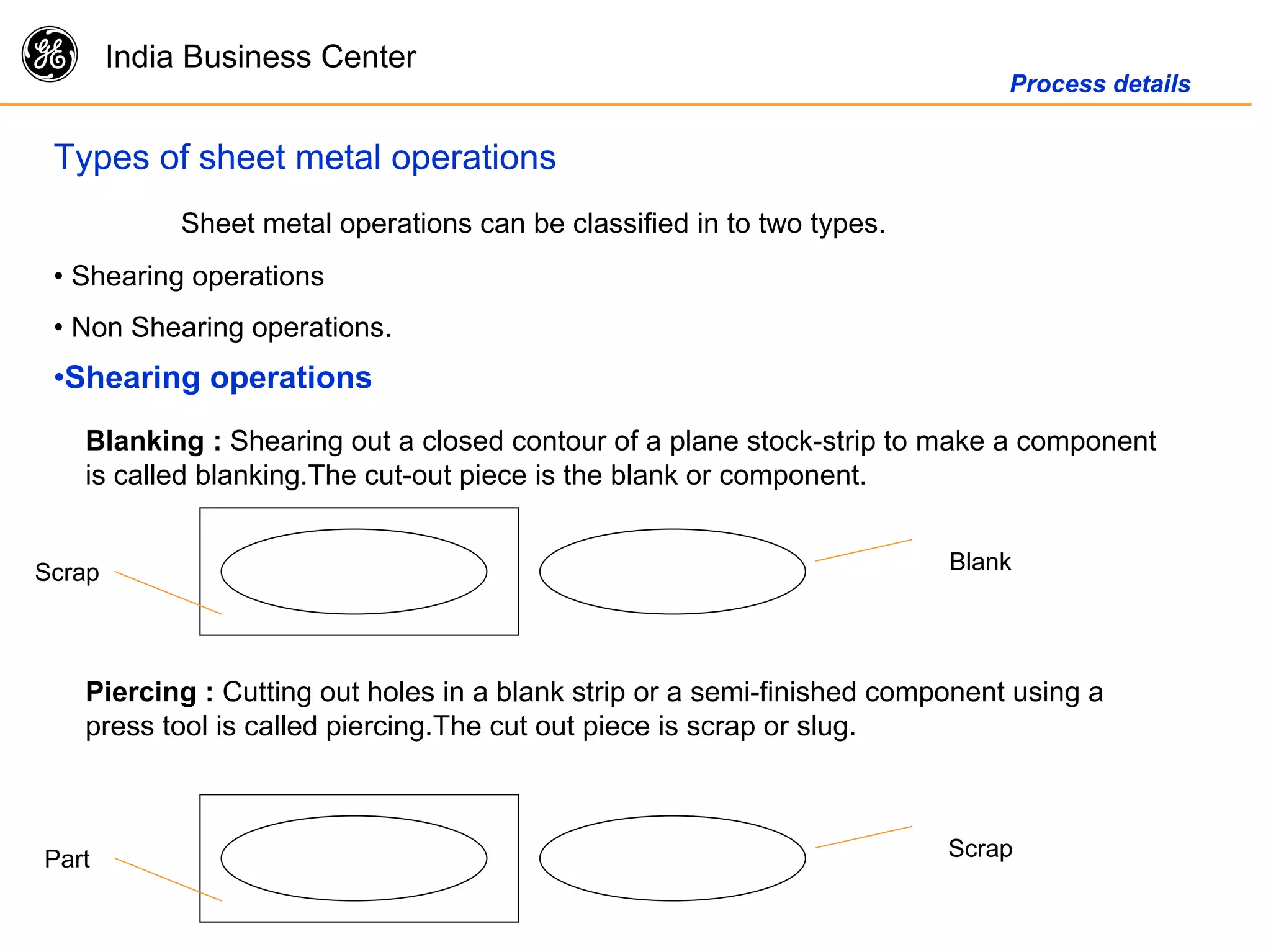

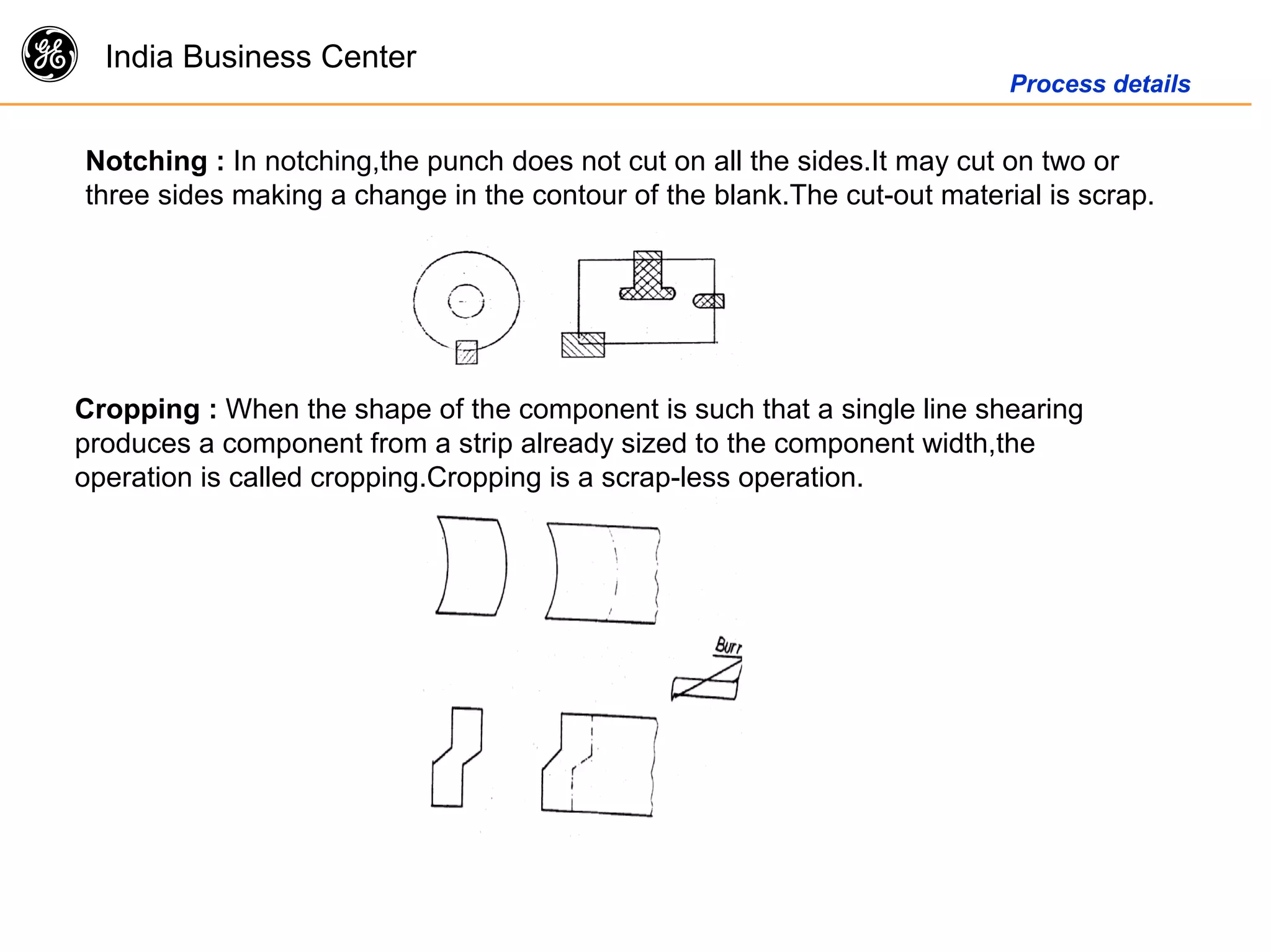

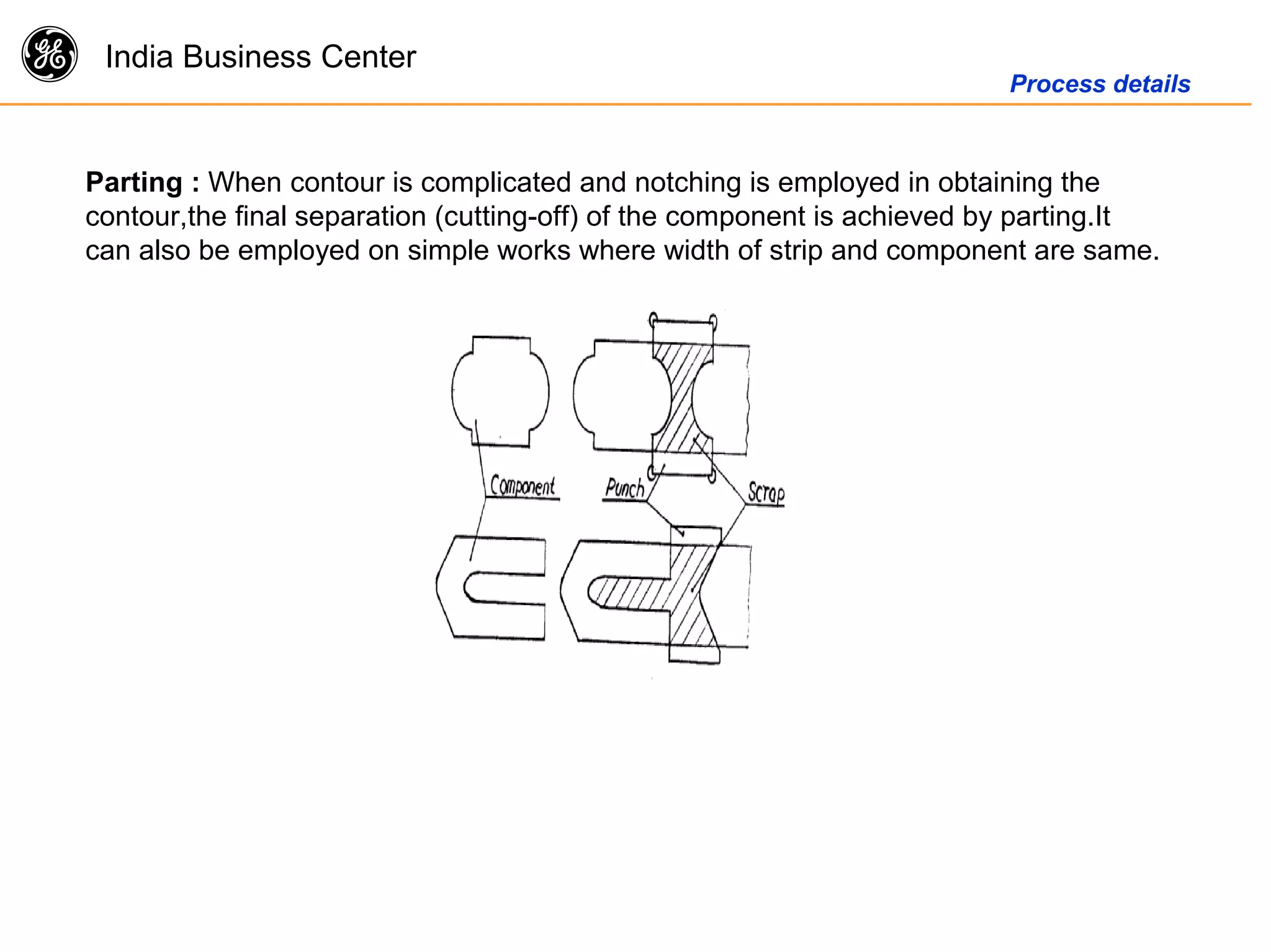

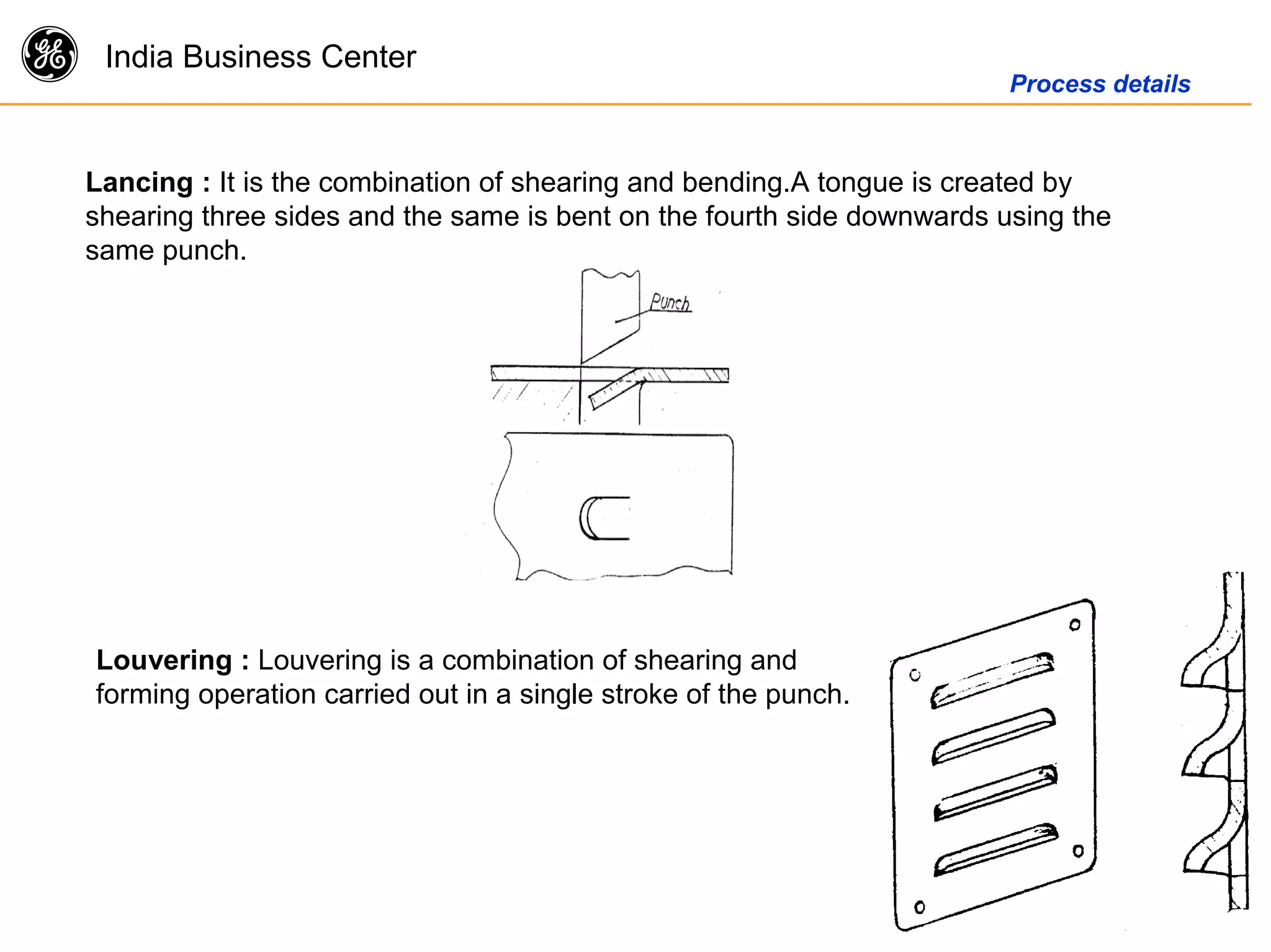

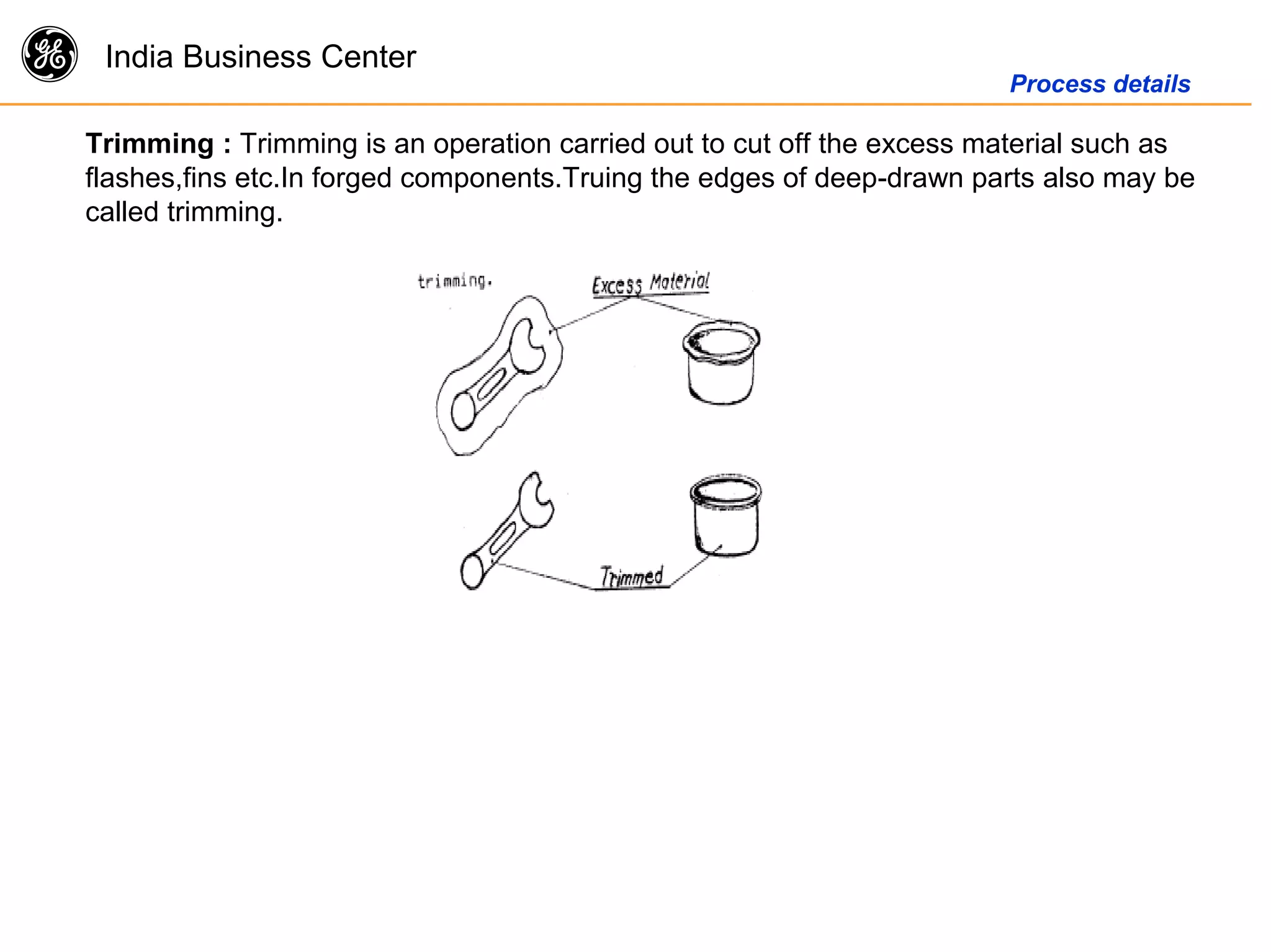

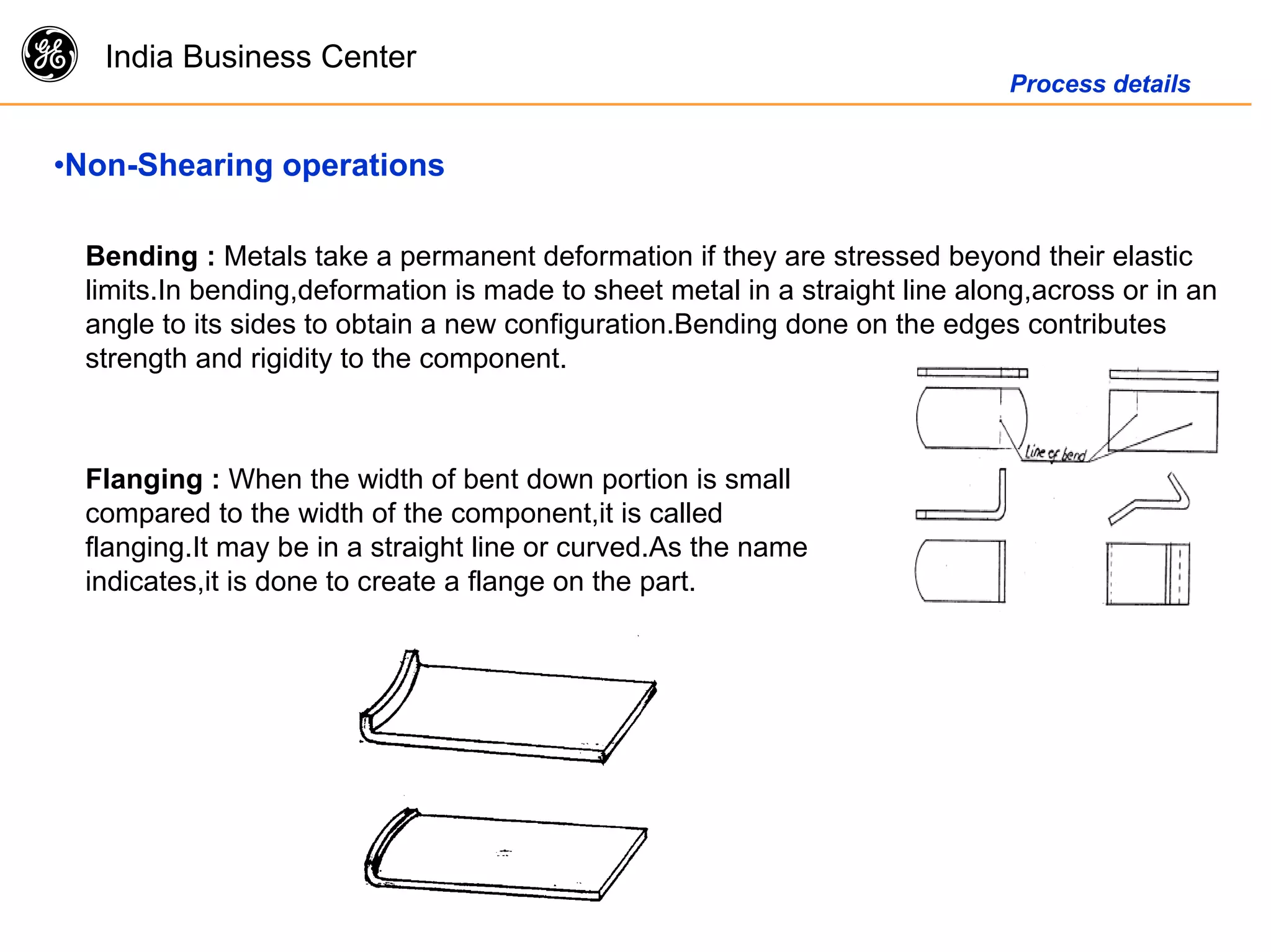

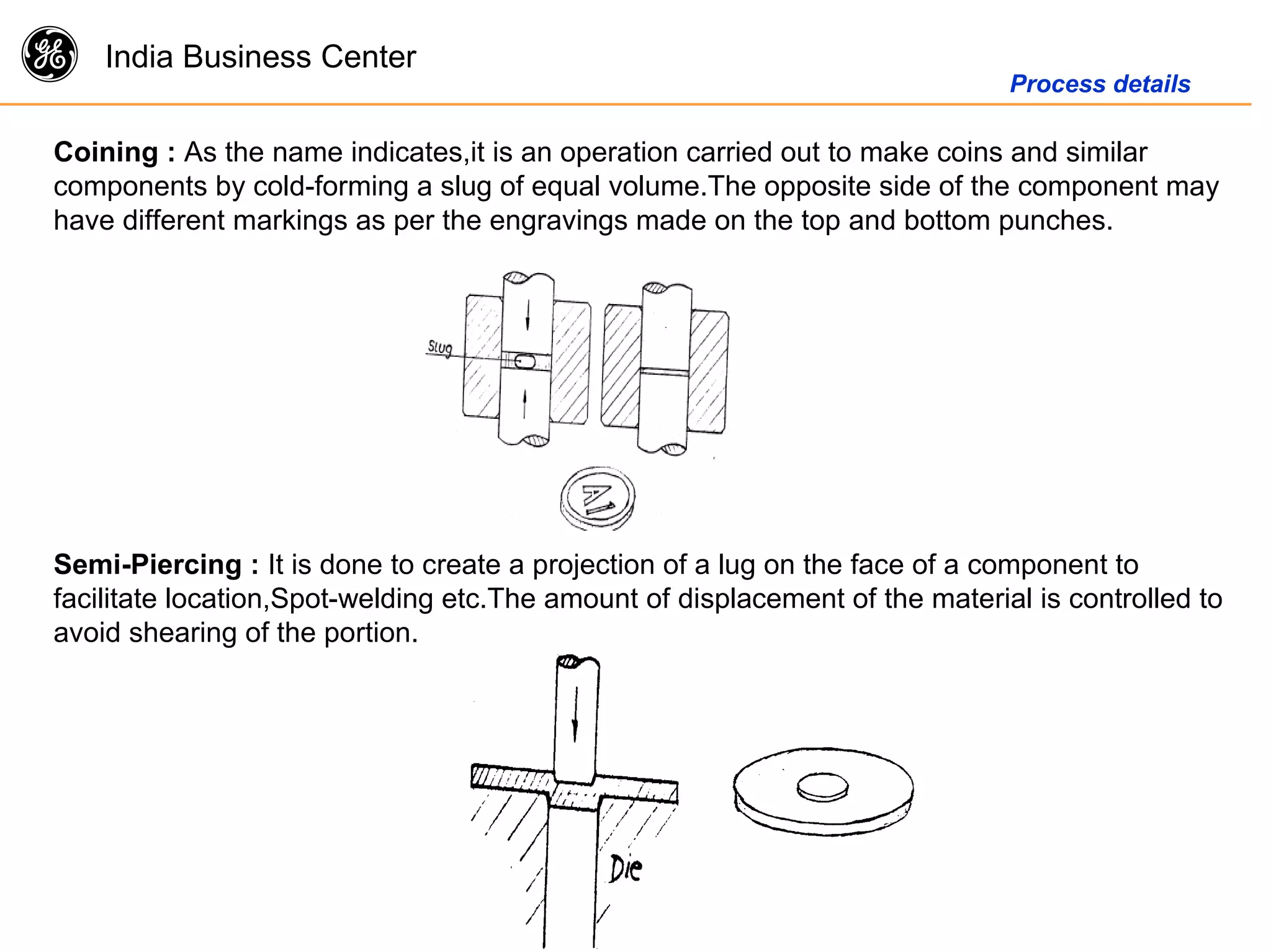

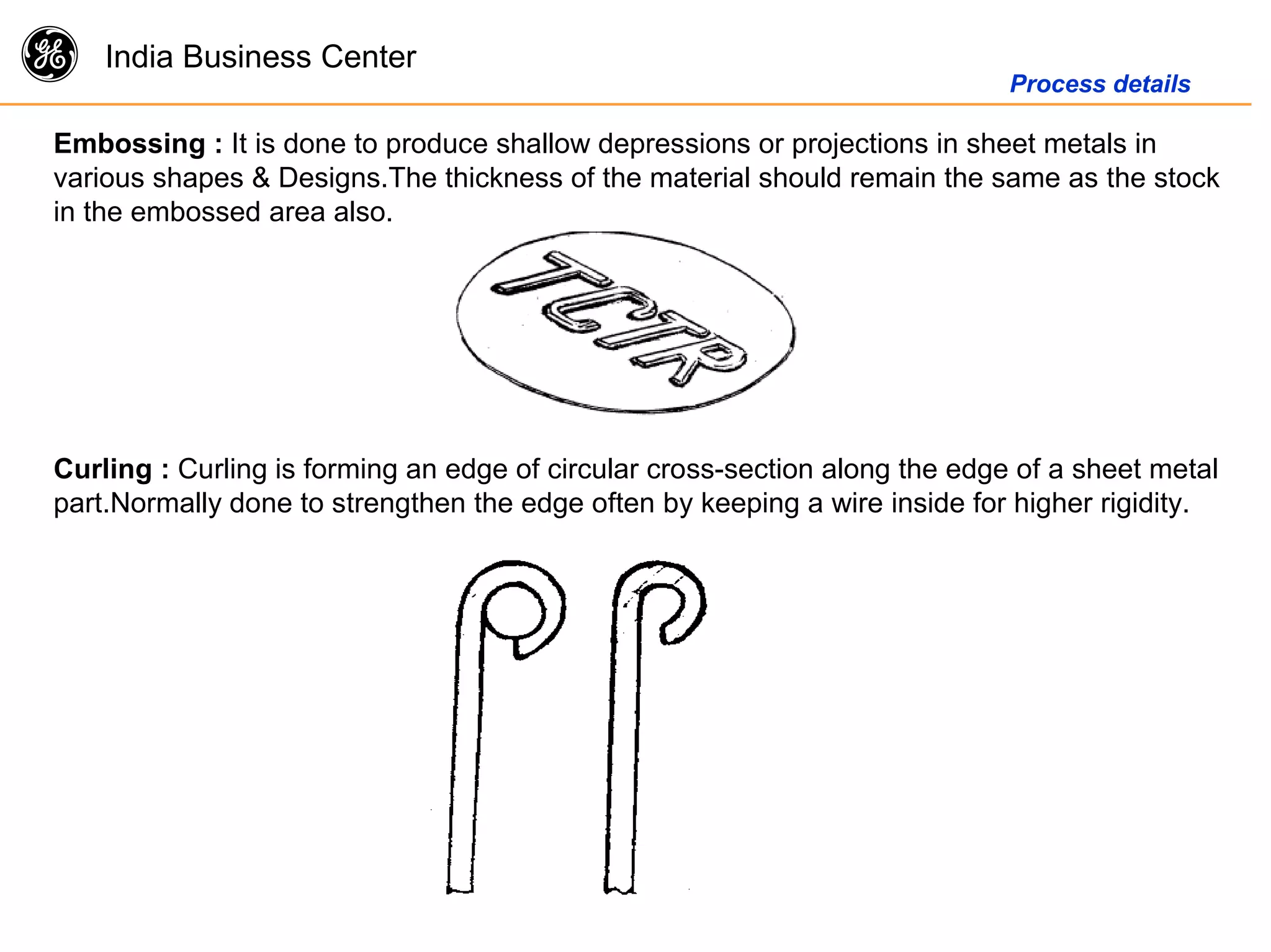

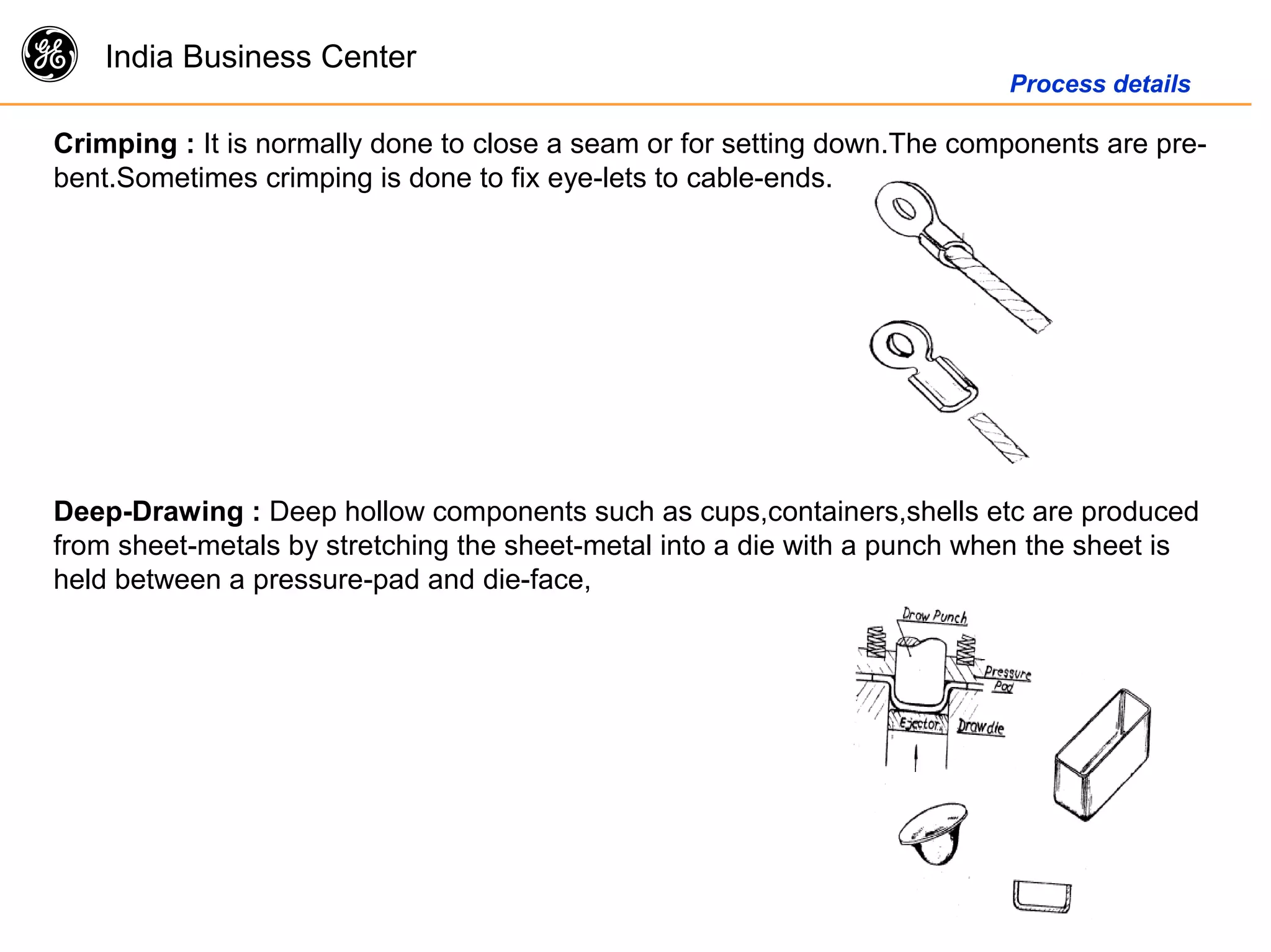

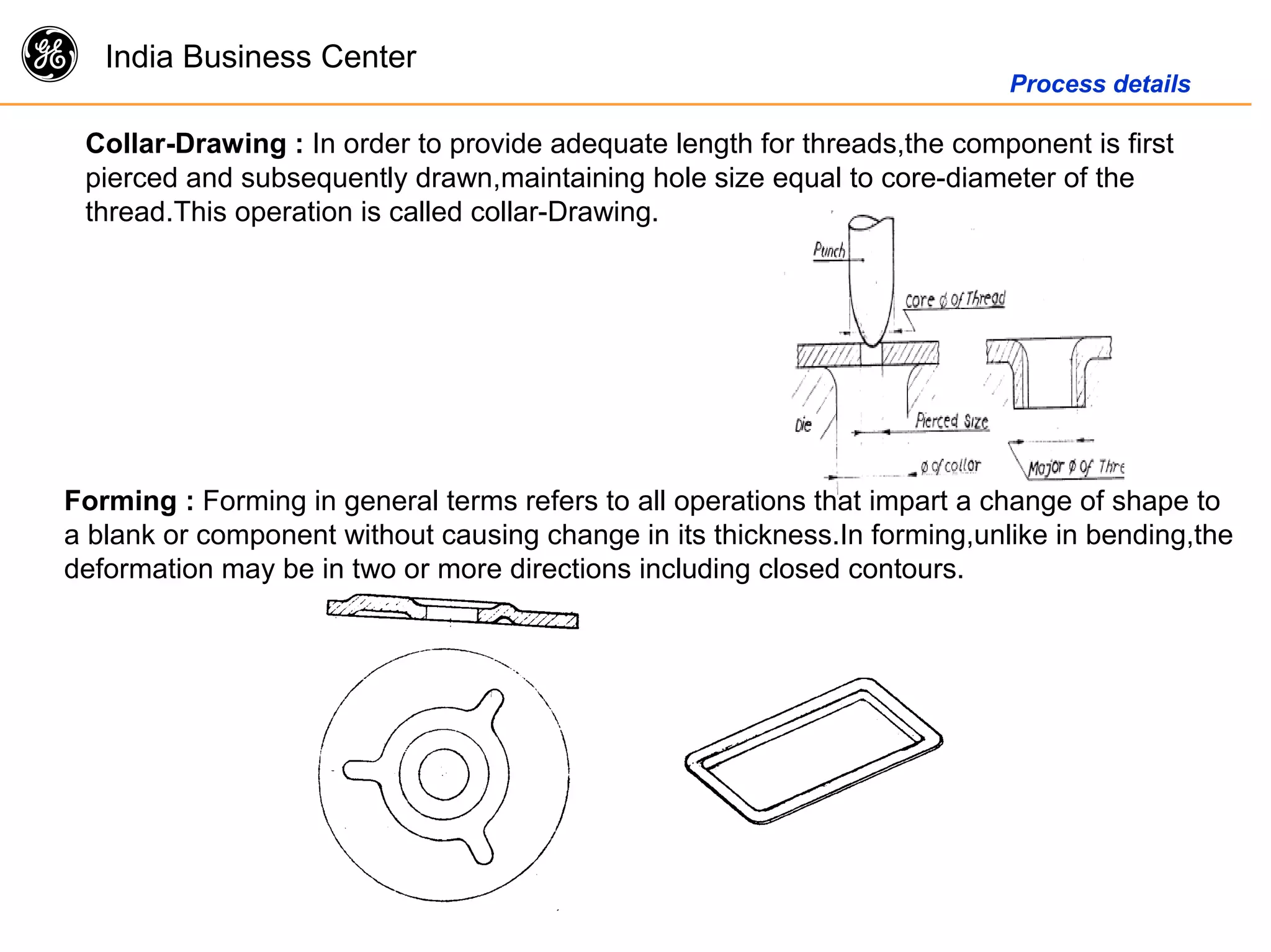

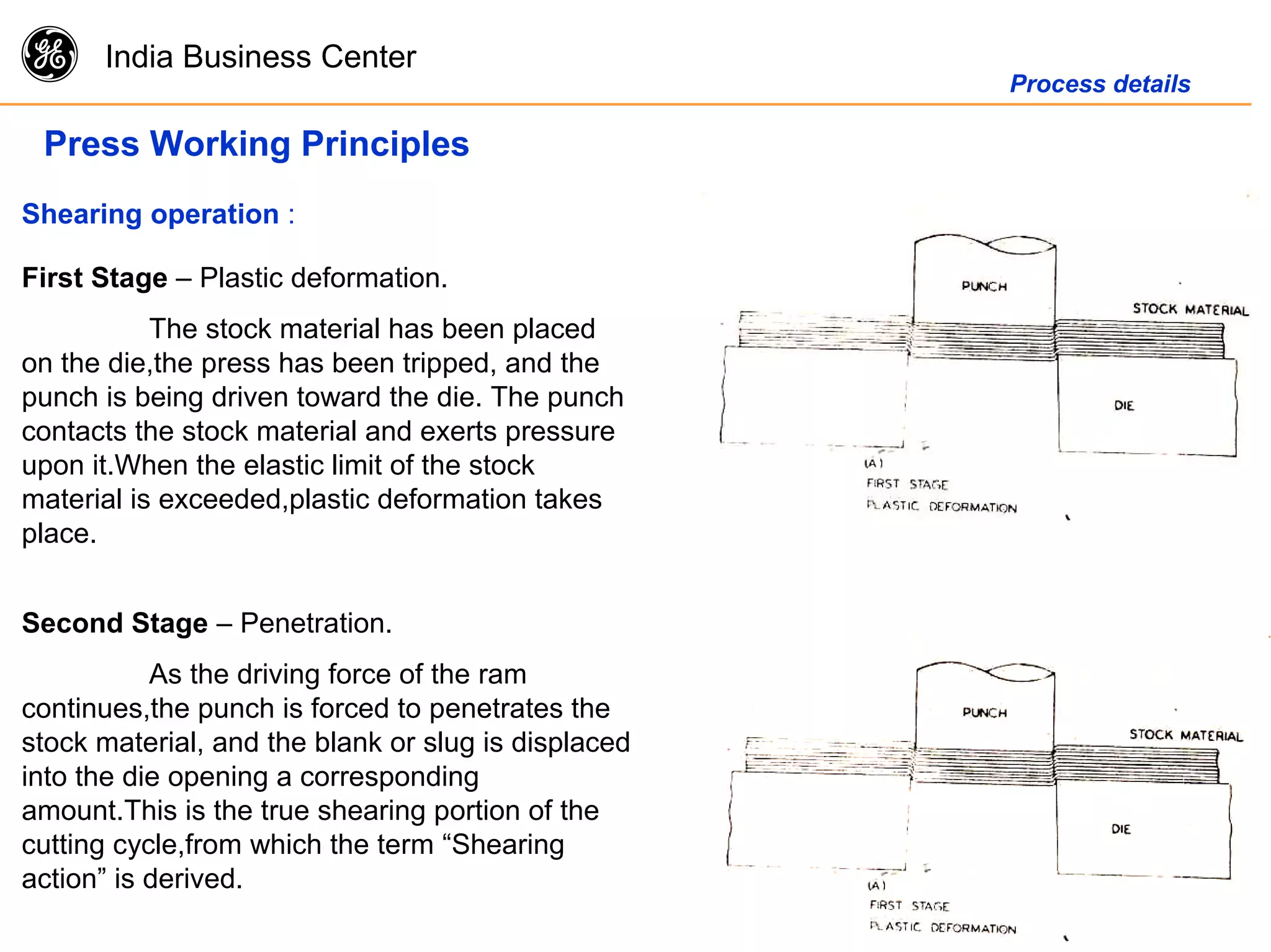

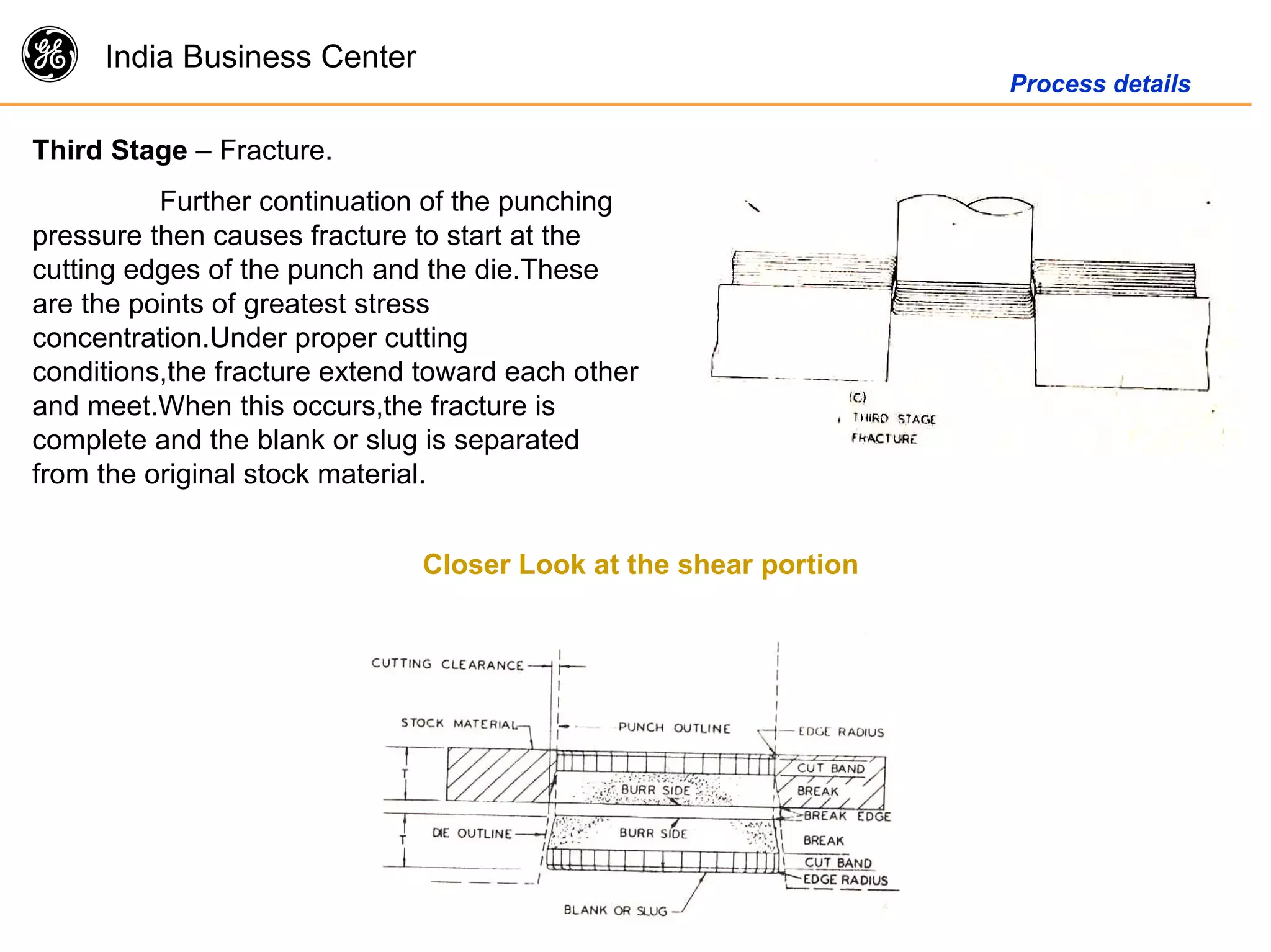

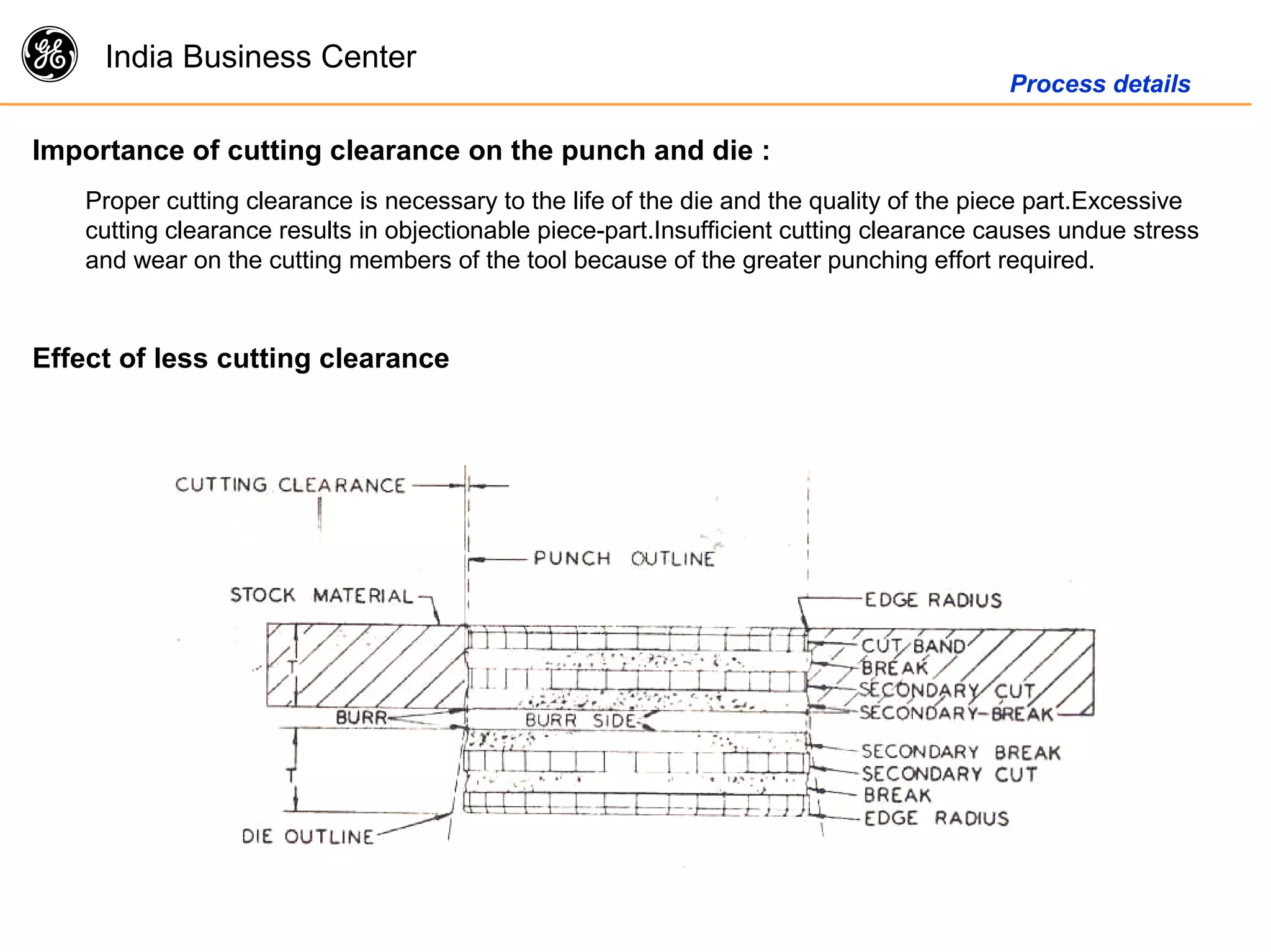

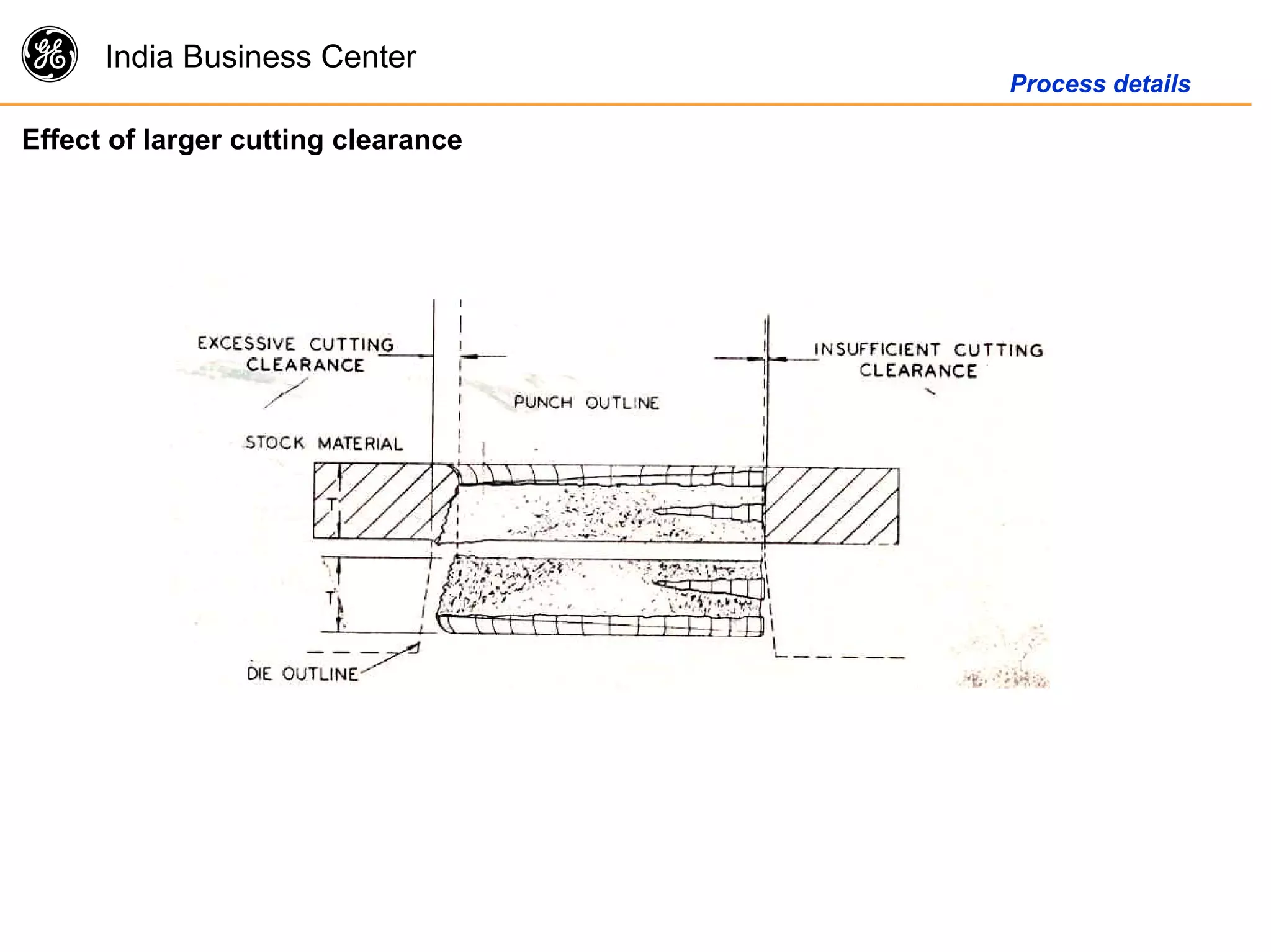

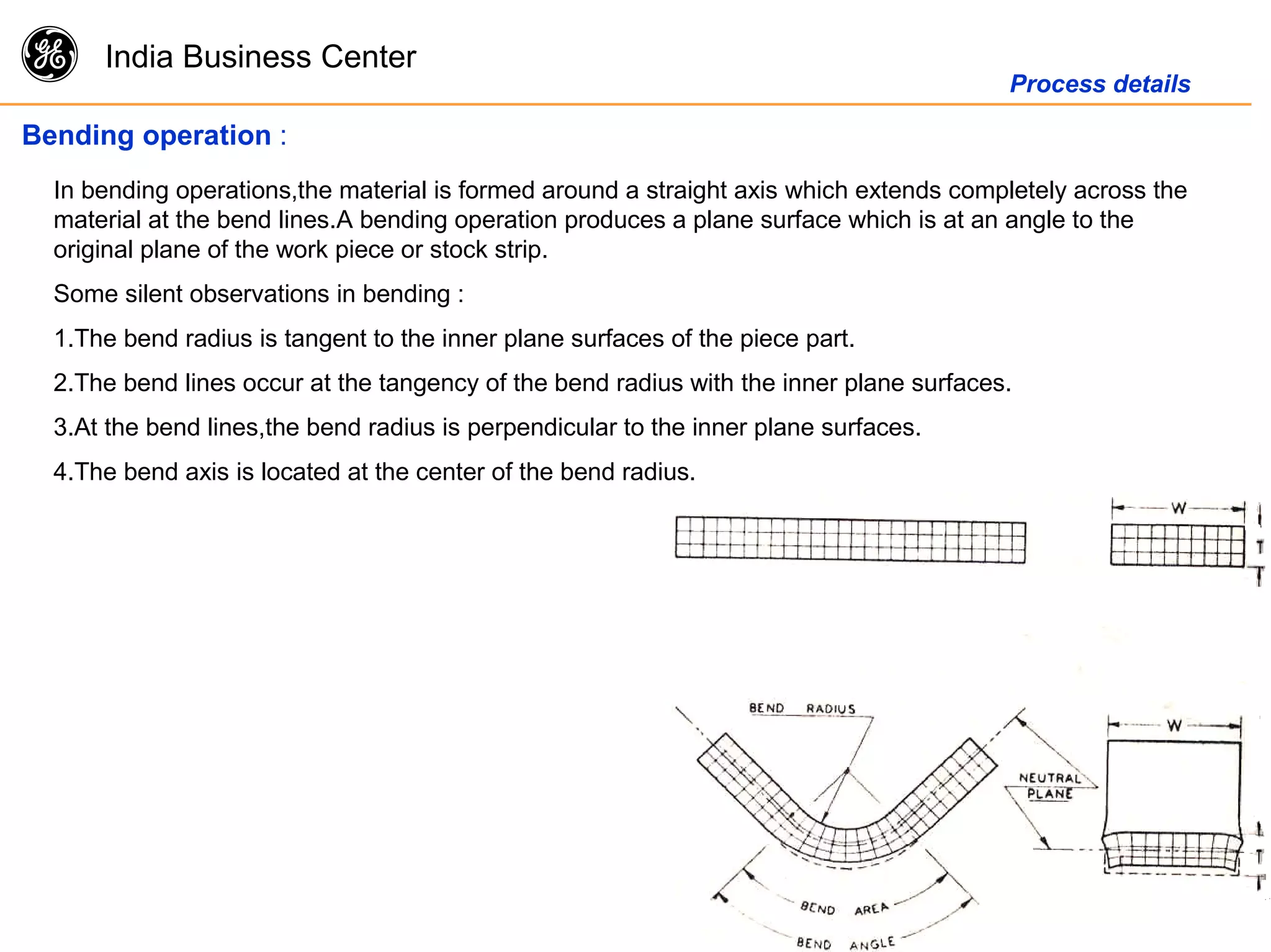

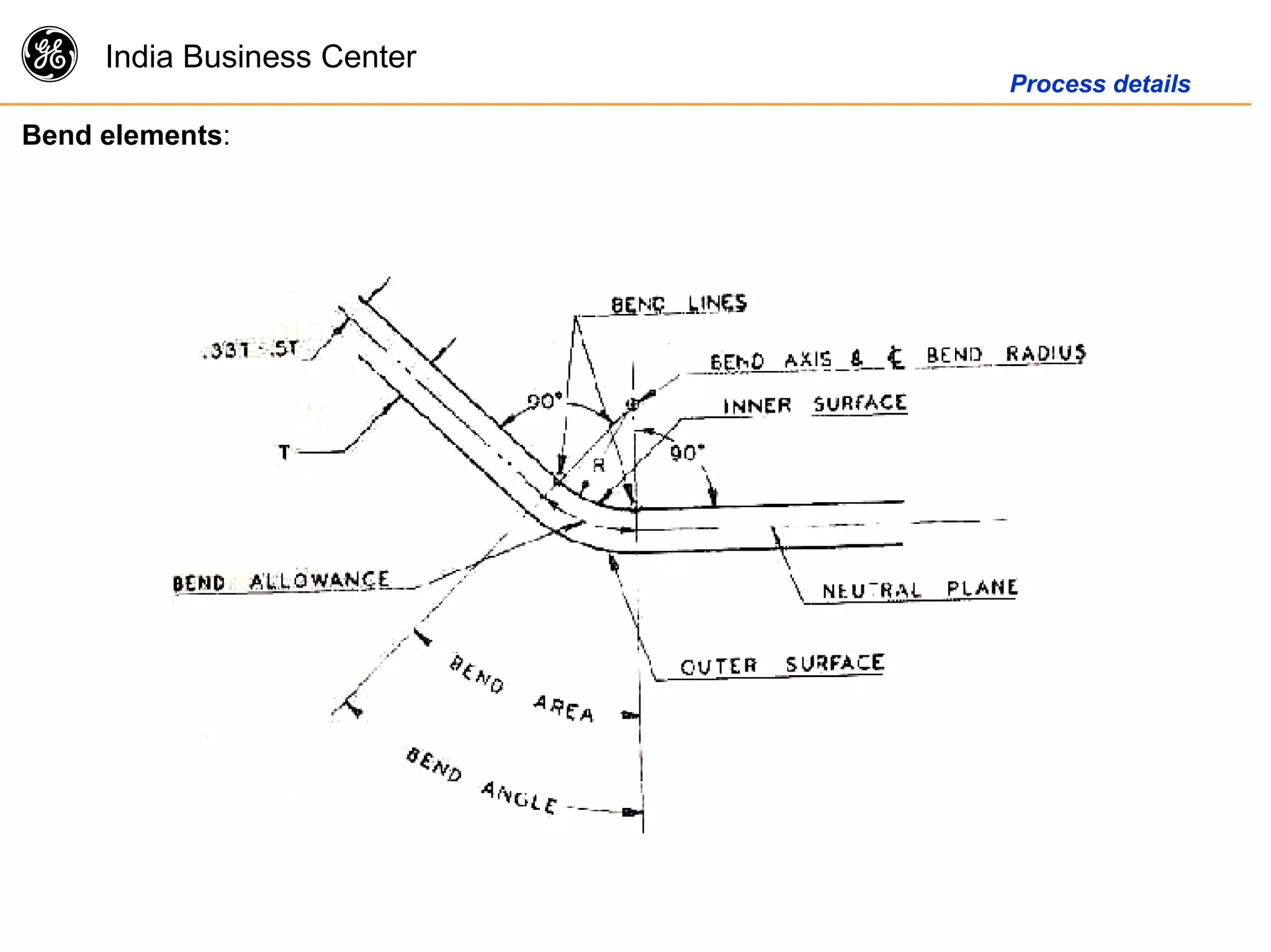

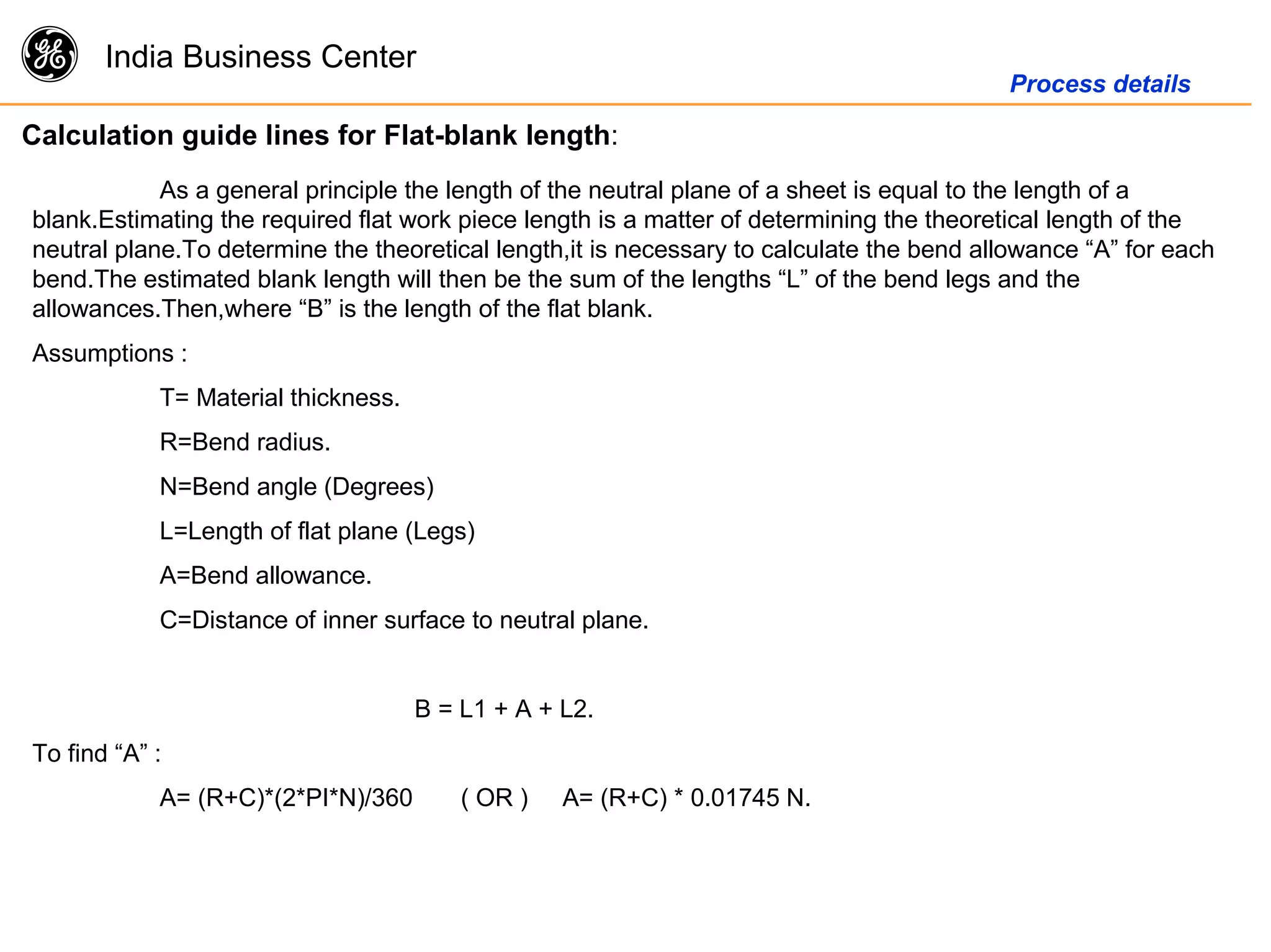

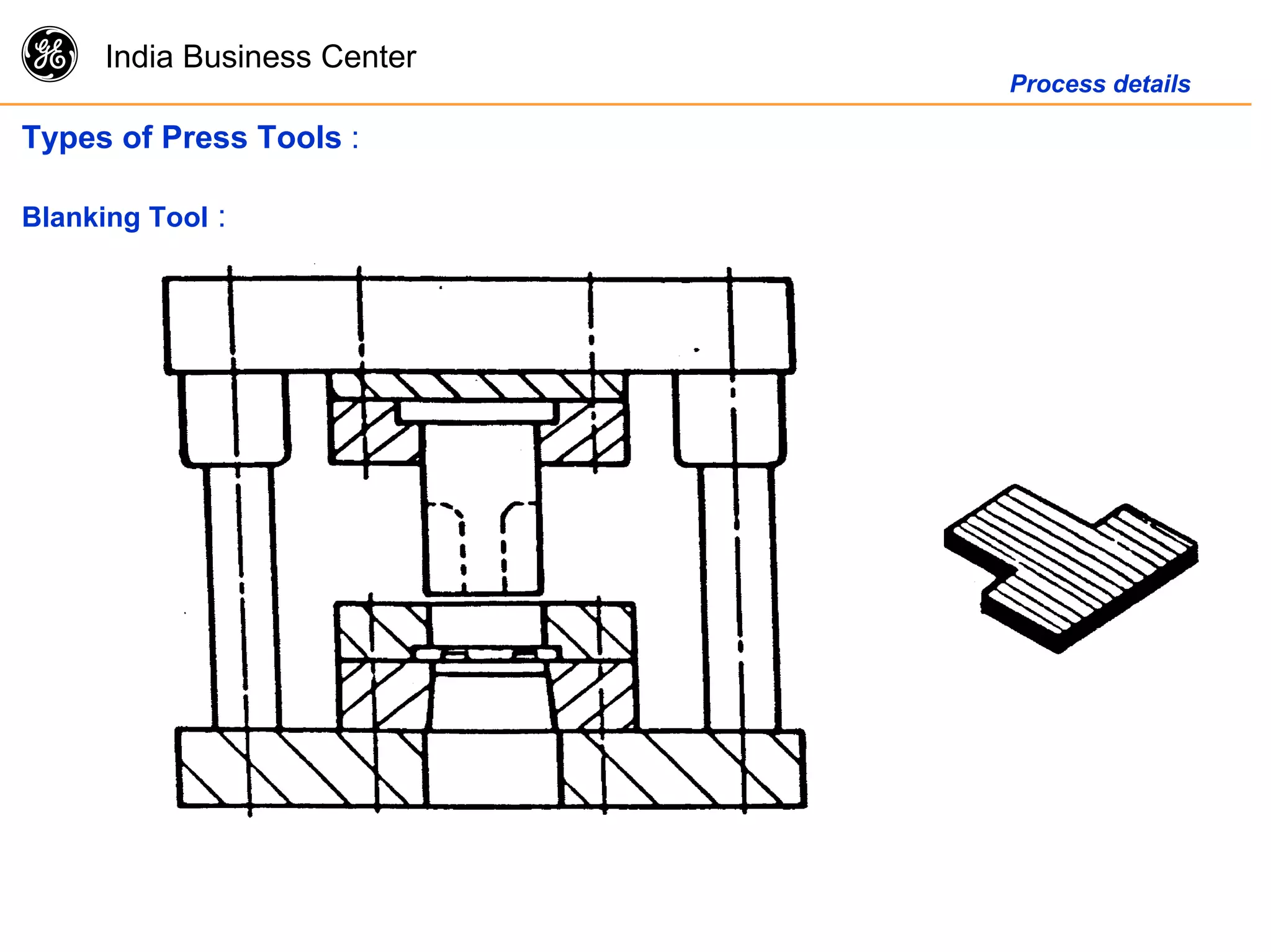

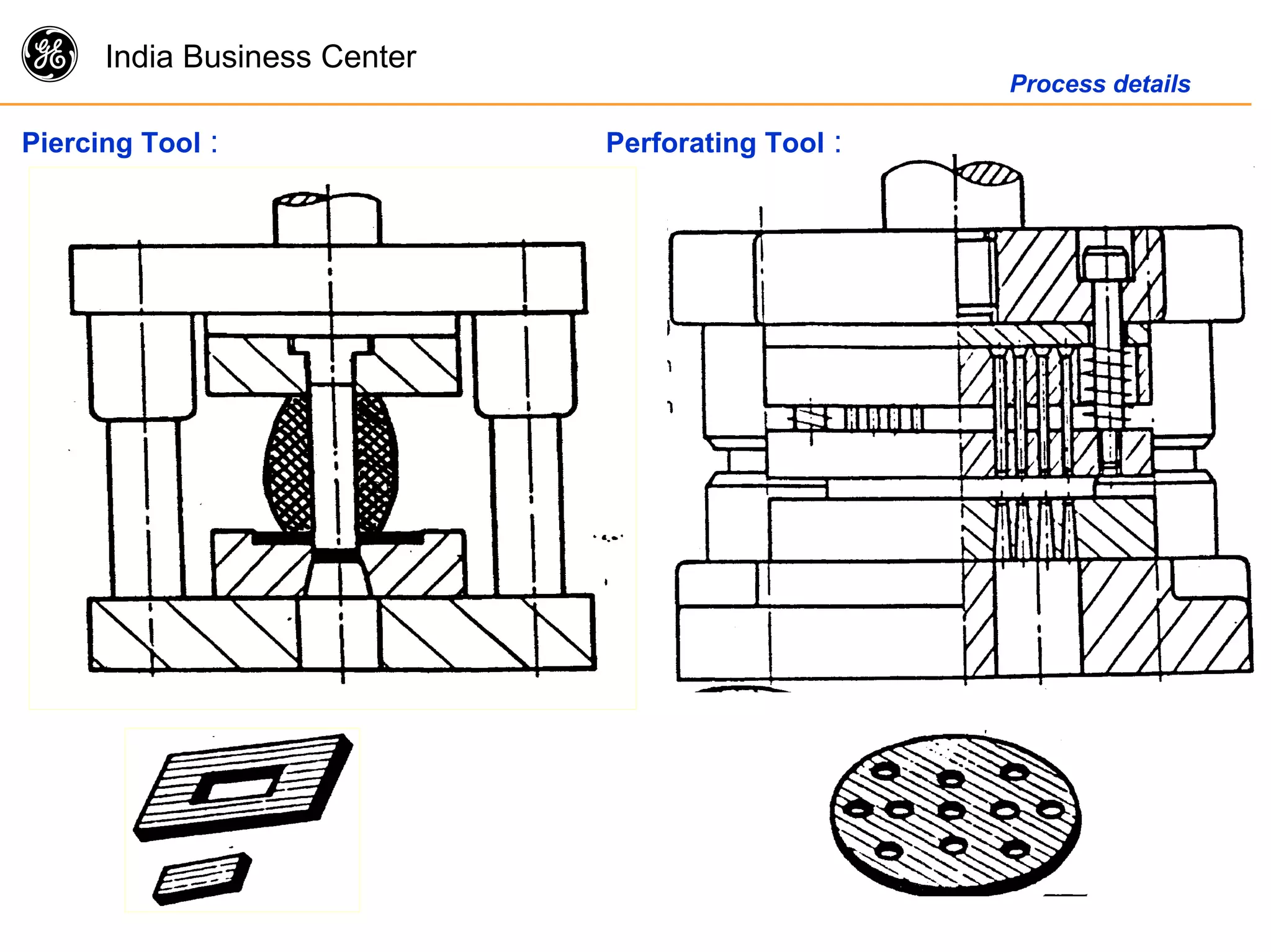

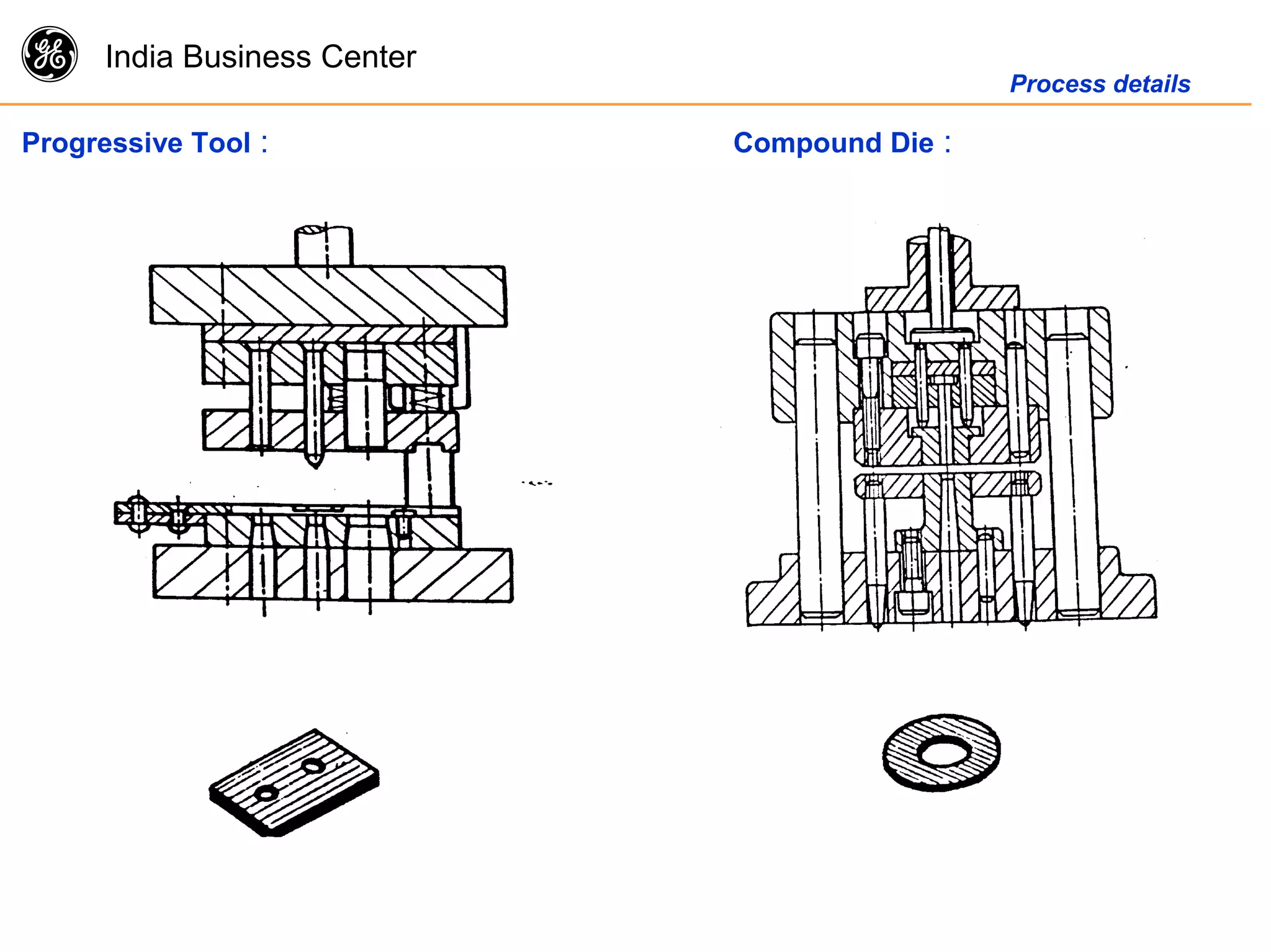

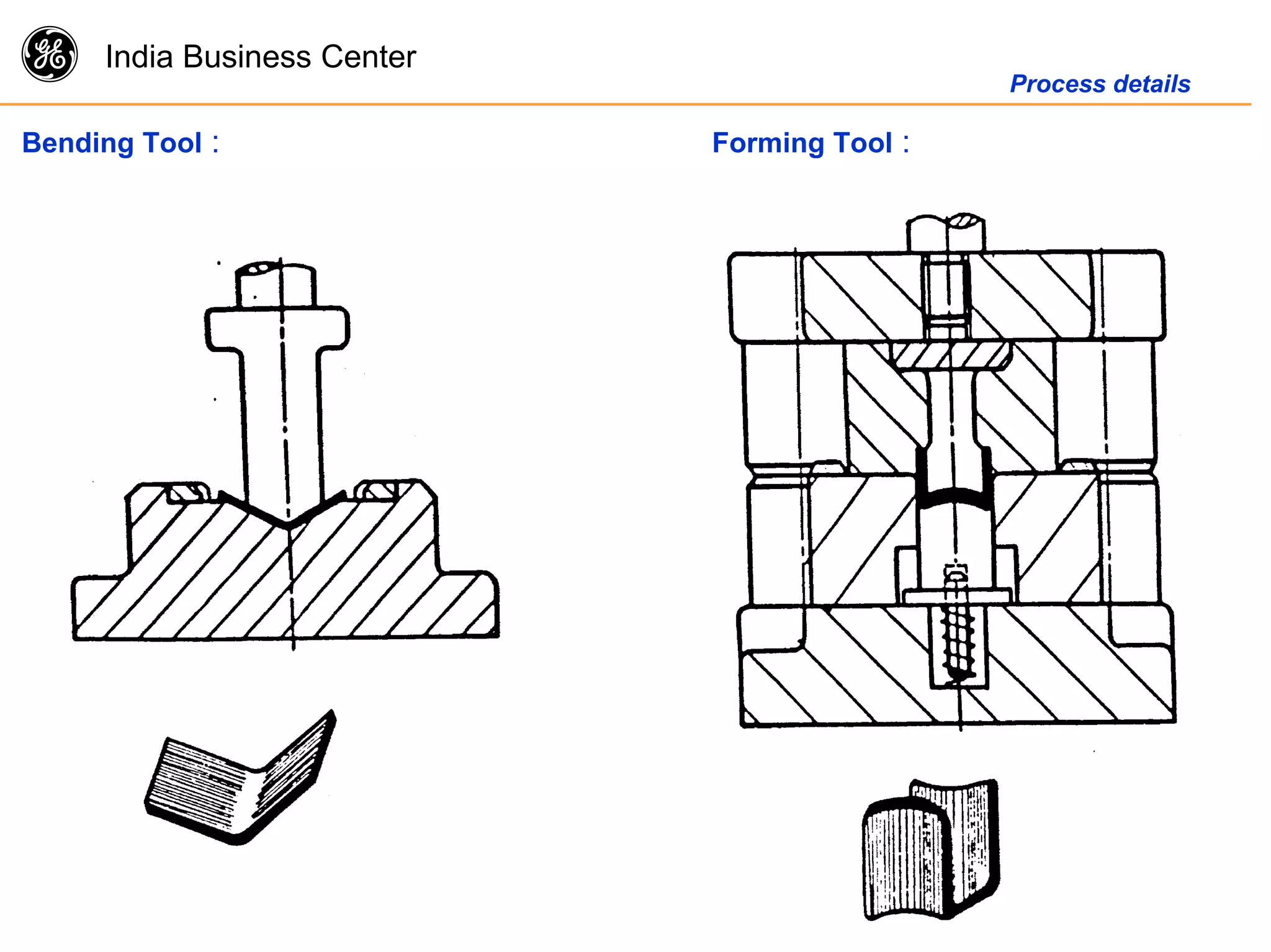

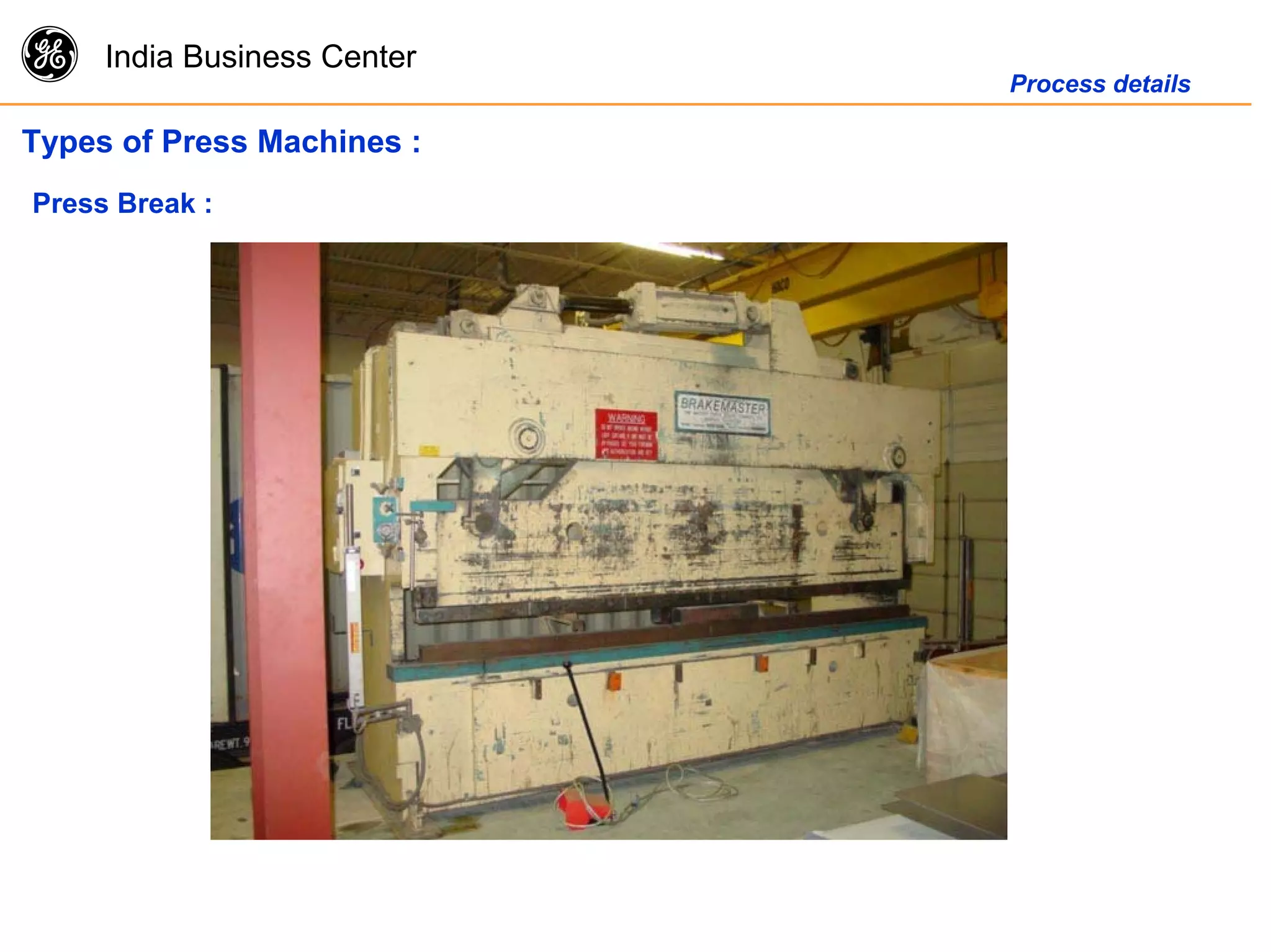

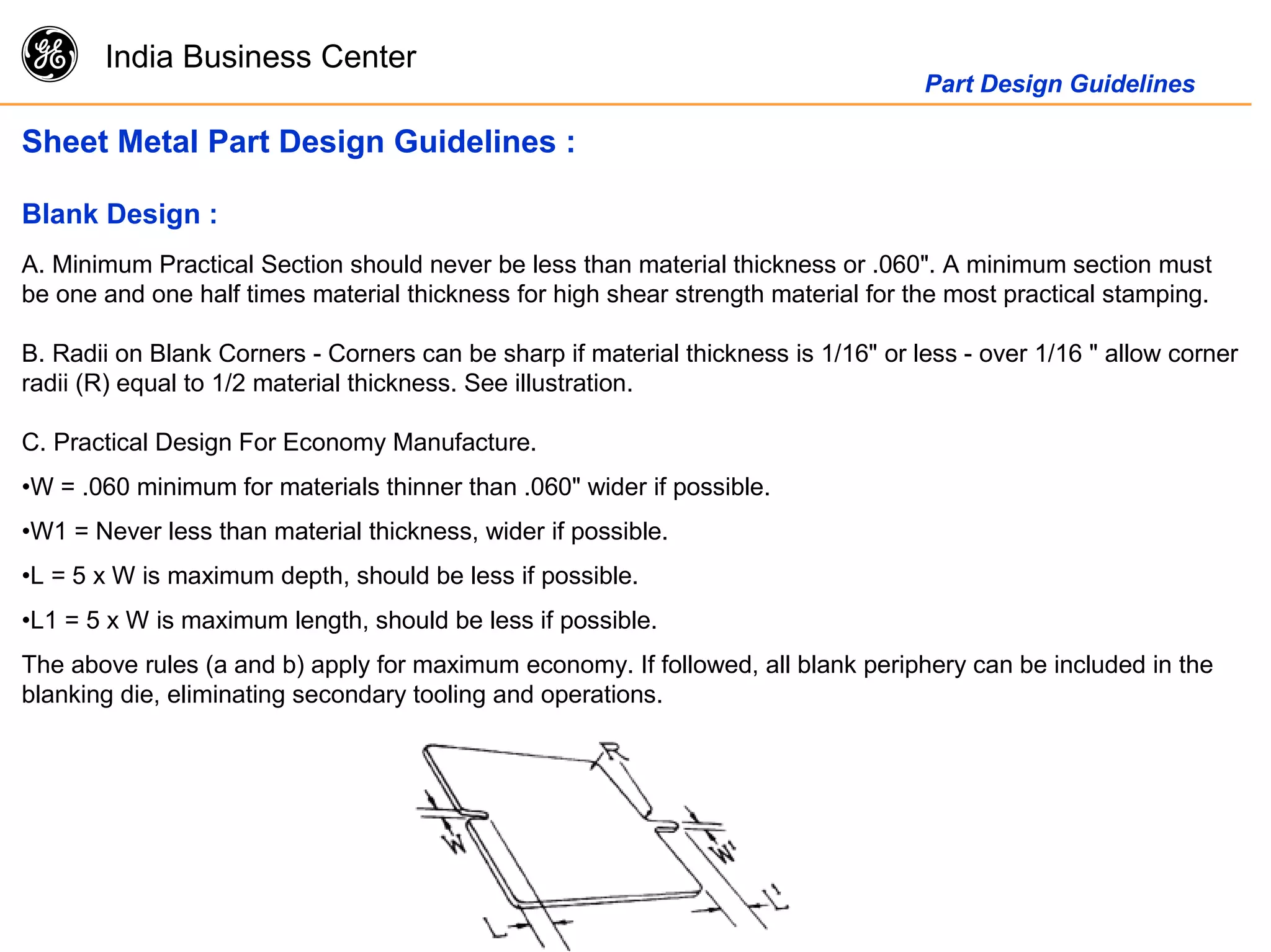

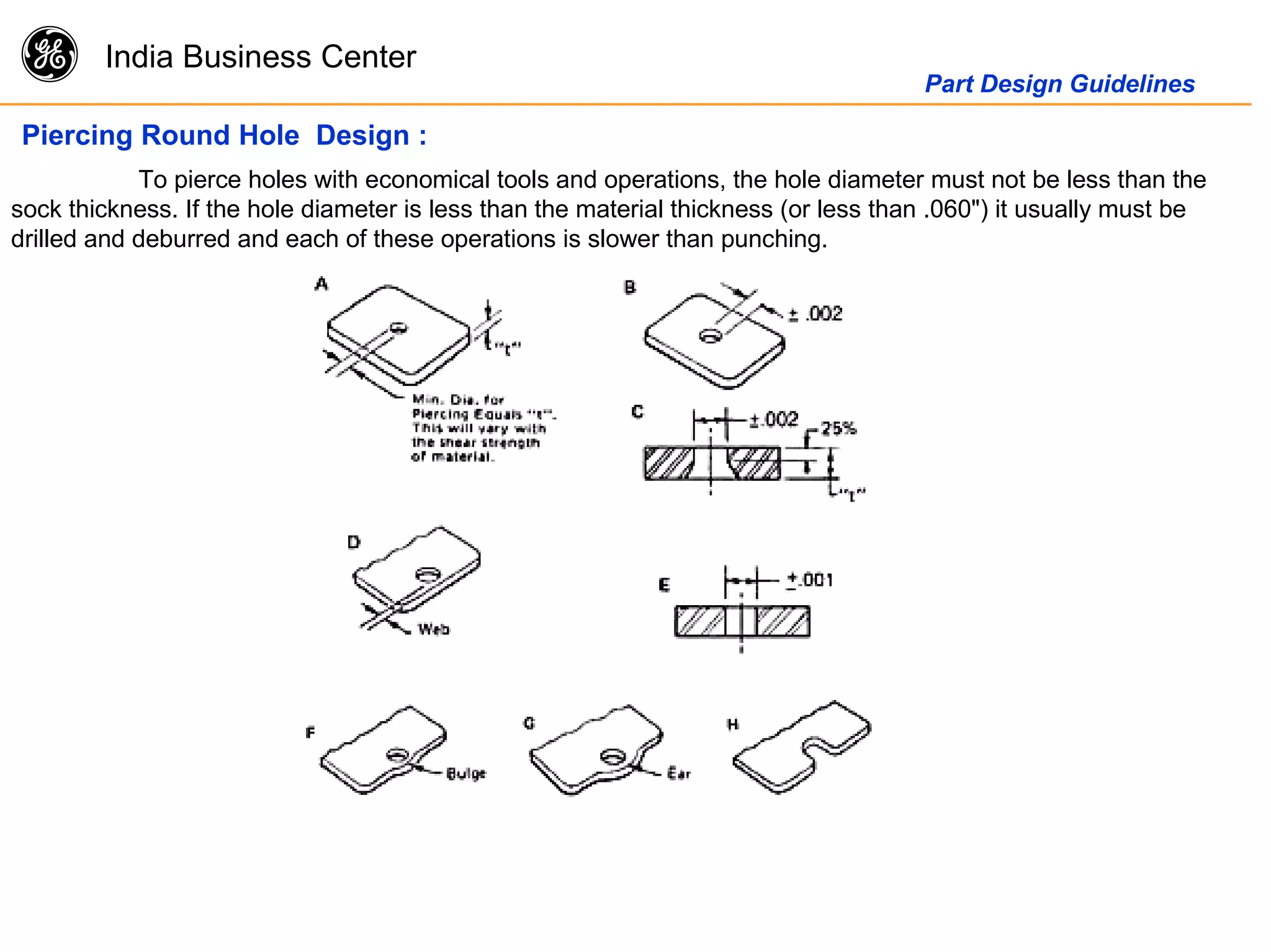

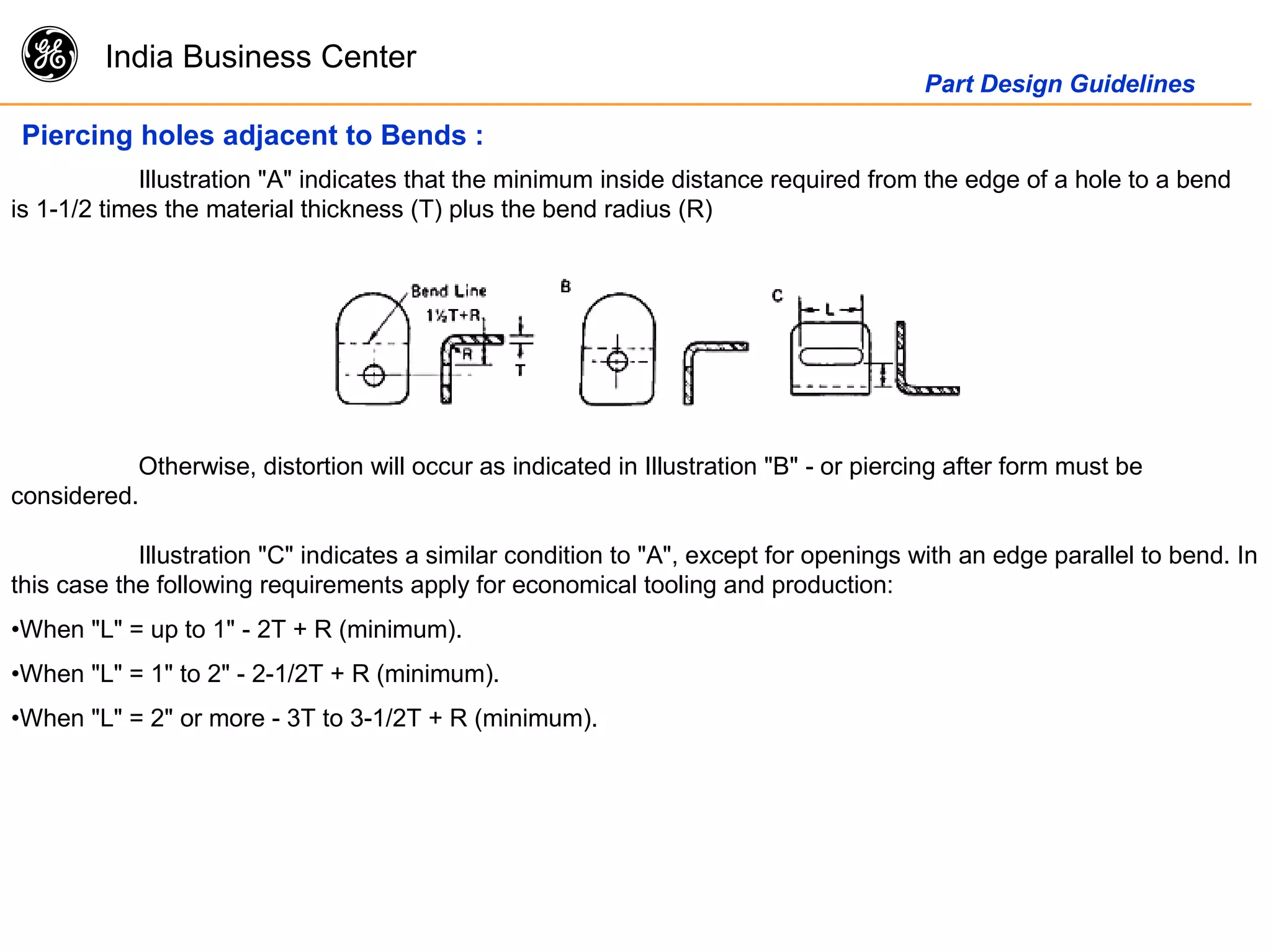

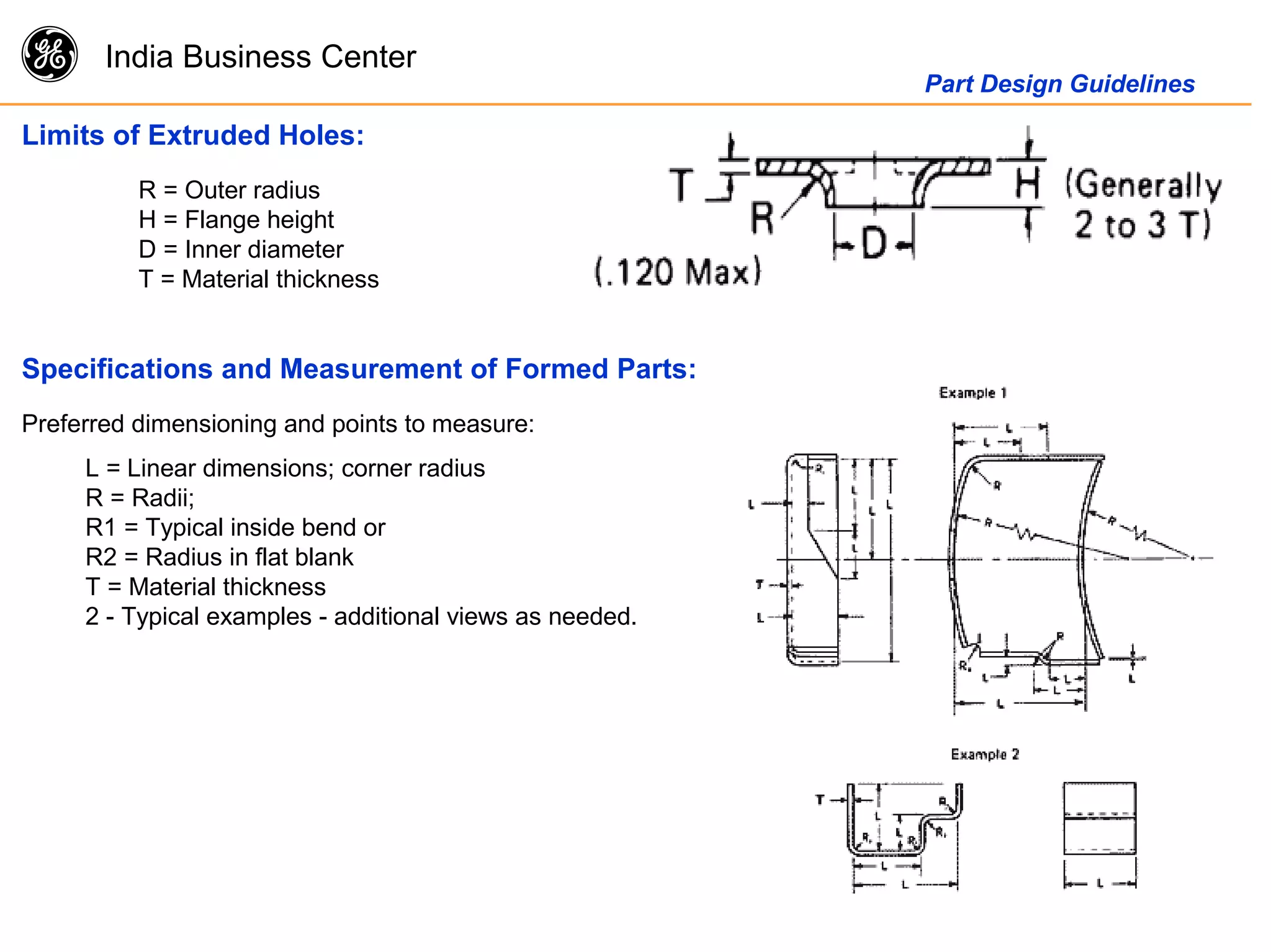

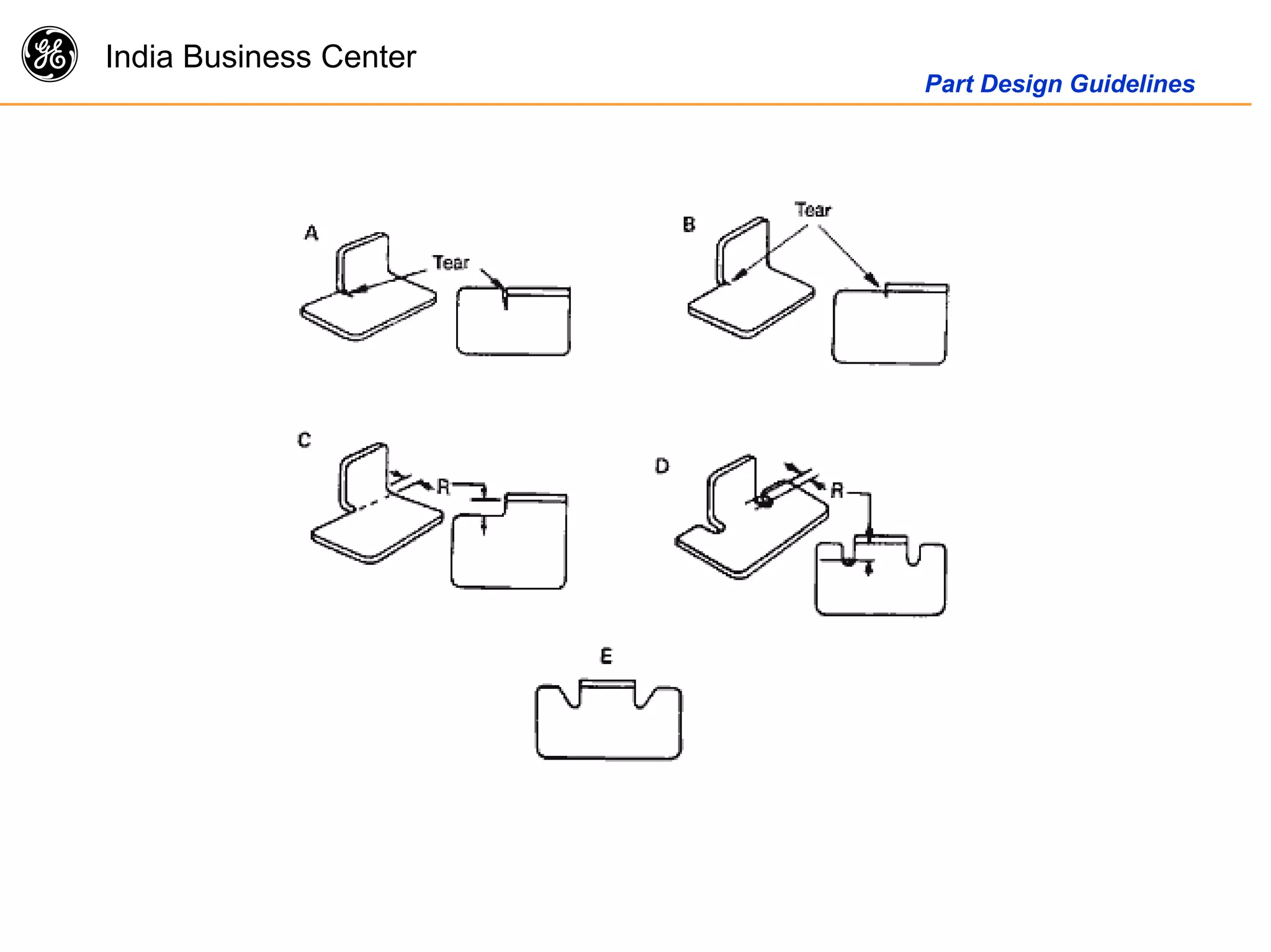

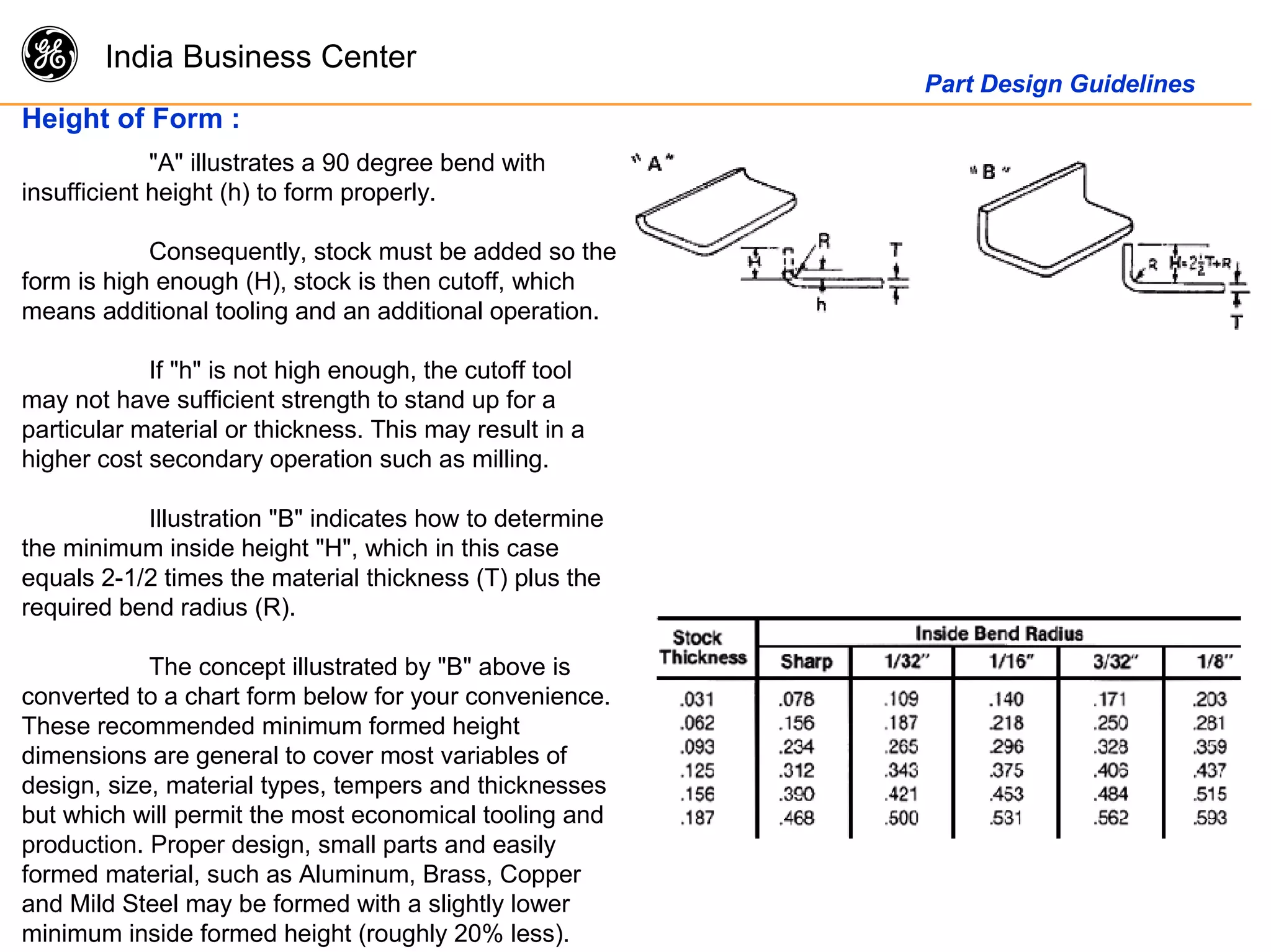

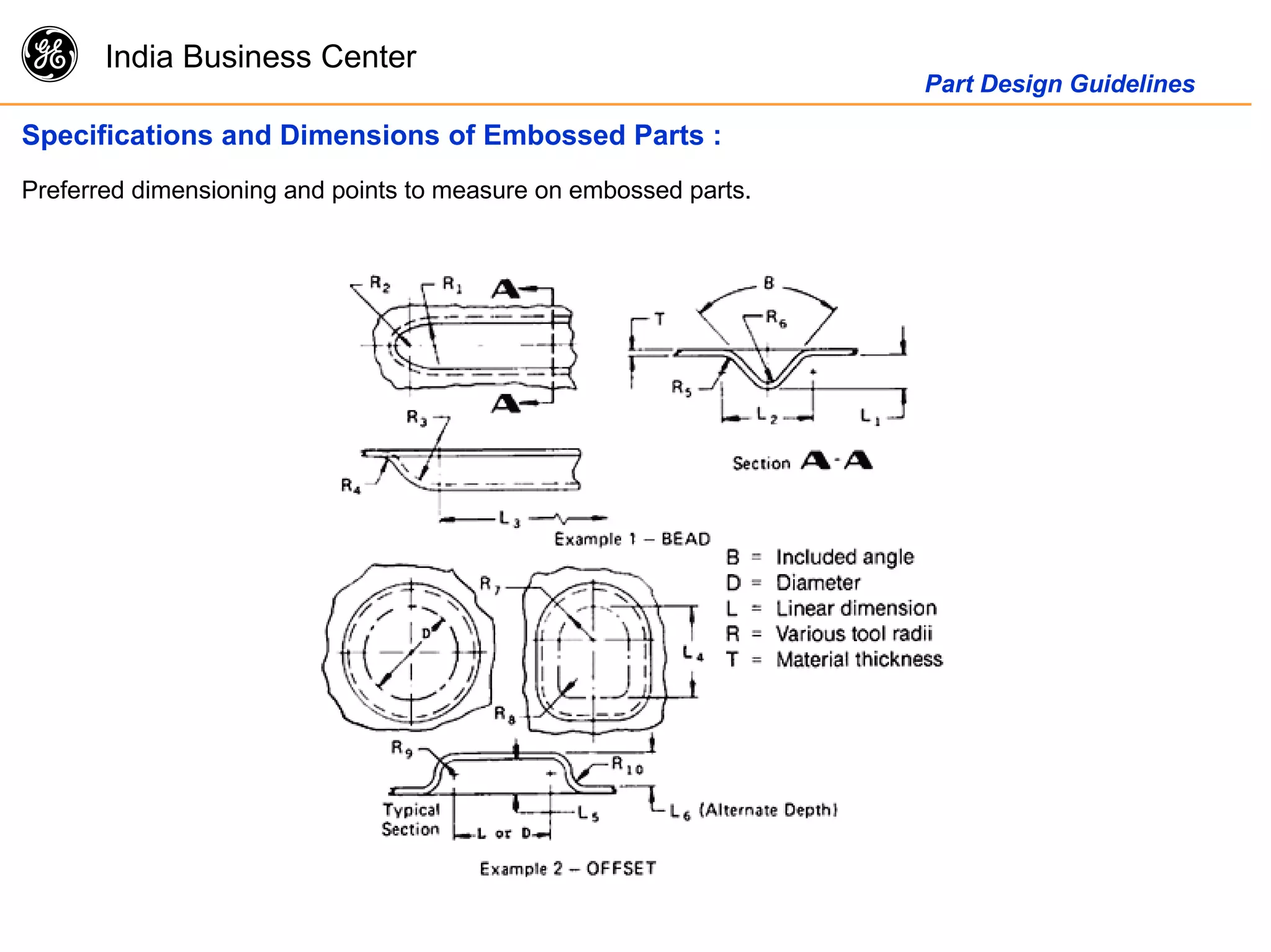

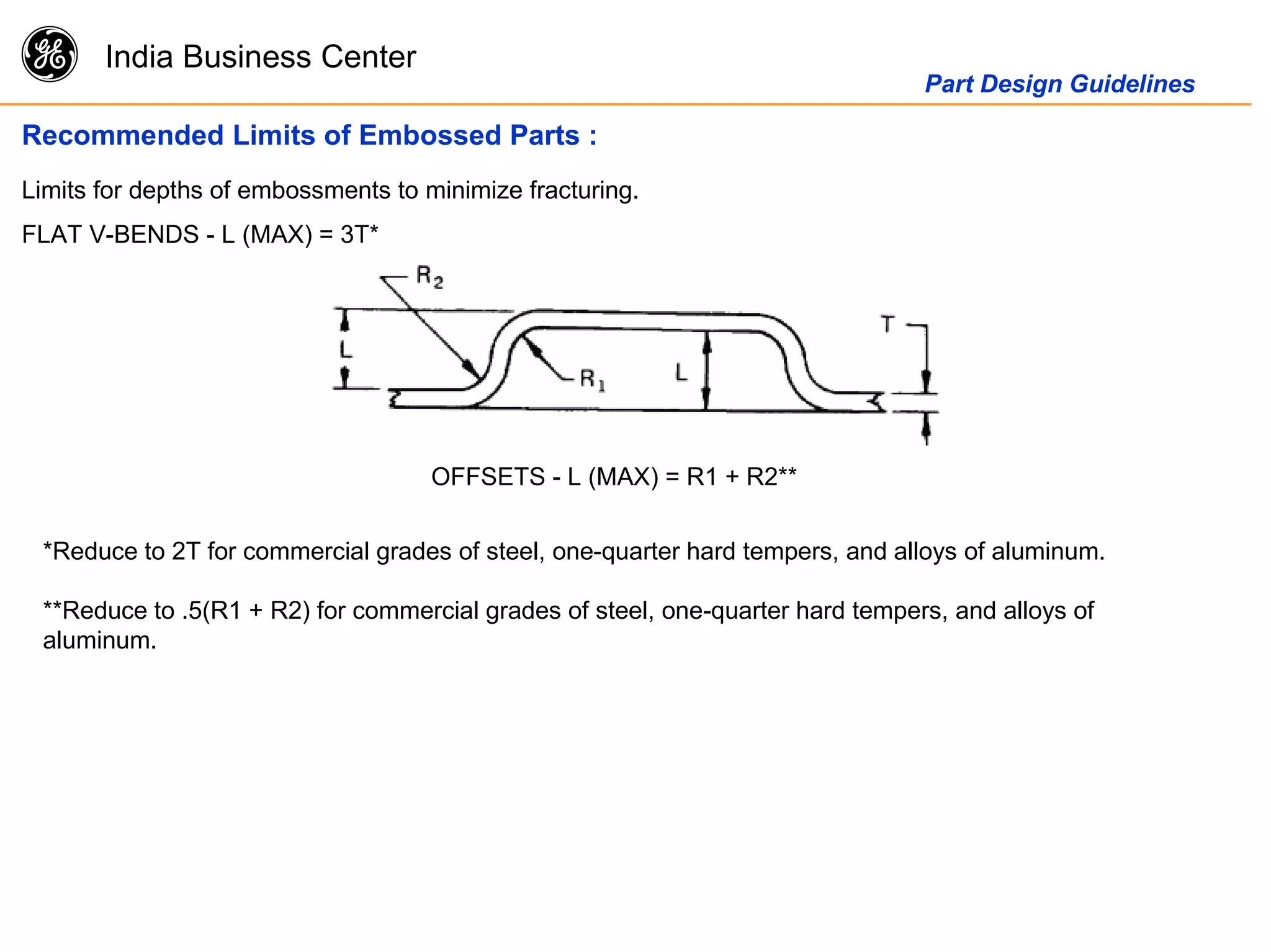

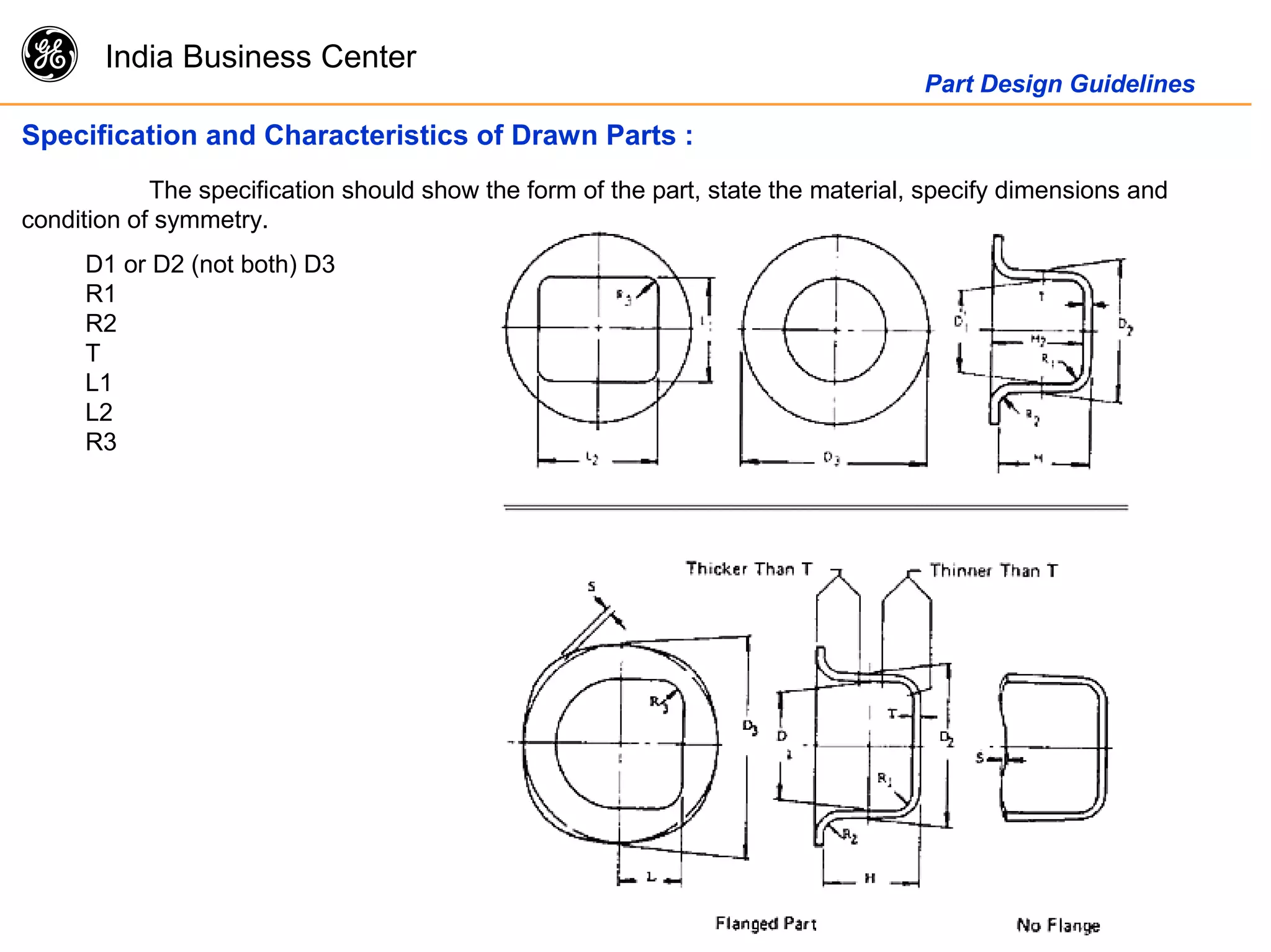

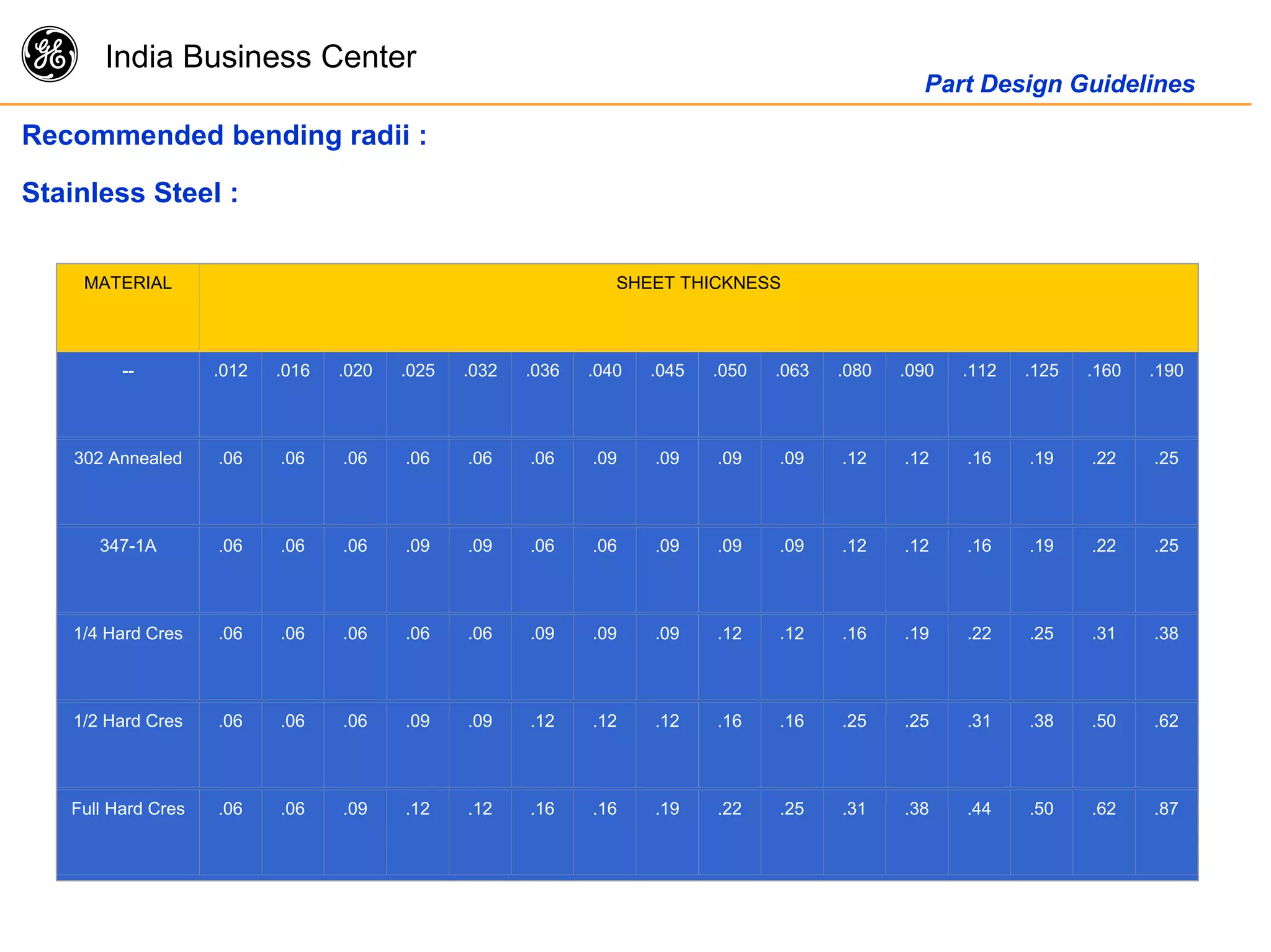

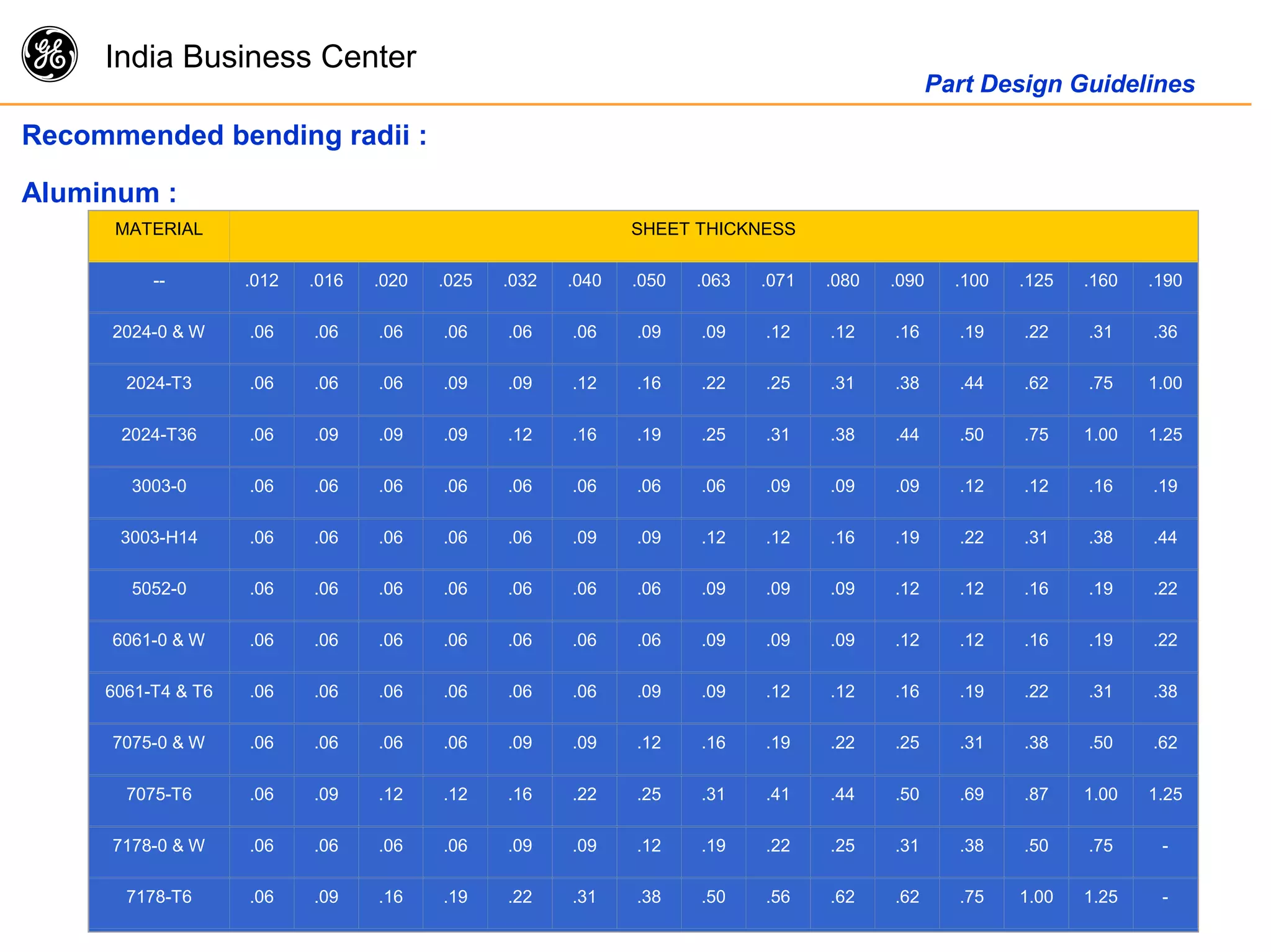

This document provides guidelines and considerations for designing sheet metal parts that can be efficiently manufactured. It discusses various sheet metal forming processes like blanking, piercing, bending, deep drawing and provides examples of different press tools. It also outlines guidelines for blank and hole design to enable economical manufacturing like minimum section sizes, radii on corners, hole diameters relative to material thickness. Process details covered include principles of plastic deformation and shearing, effects of cutting clearance and calculating flat blank length for bending.