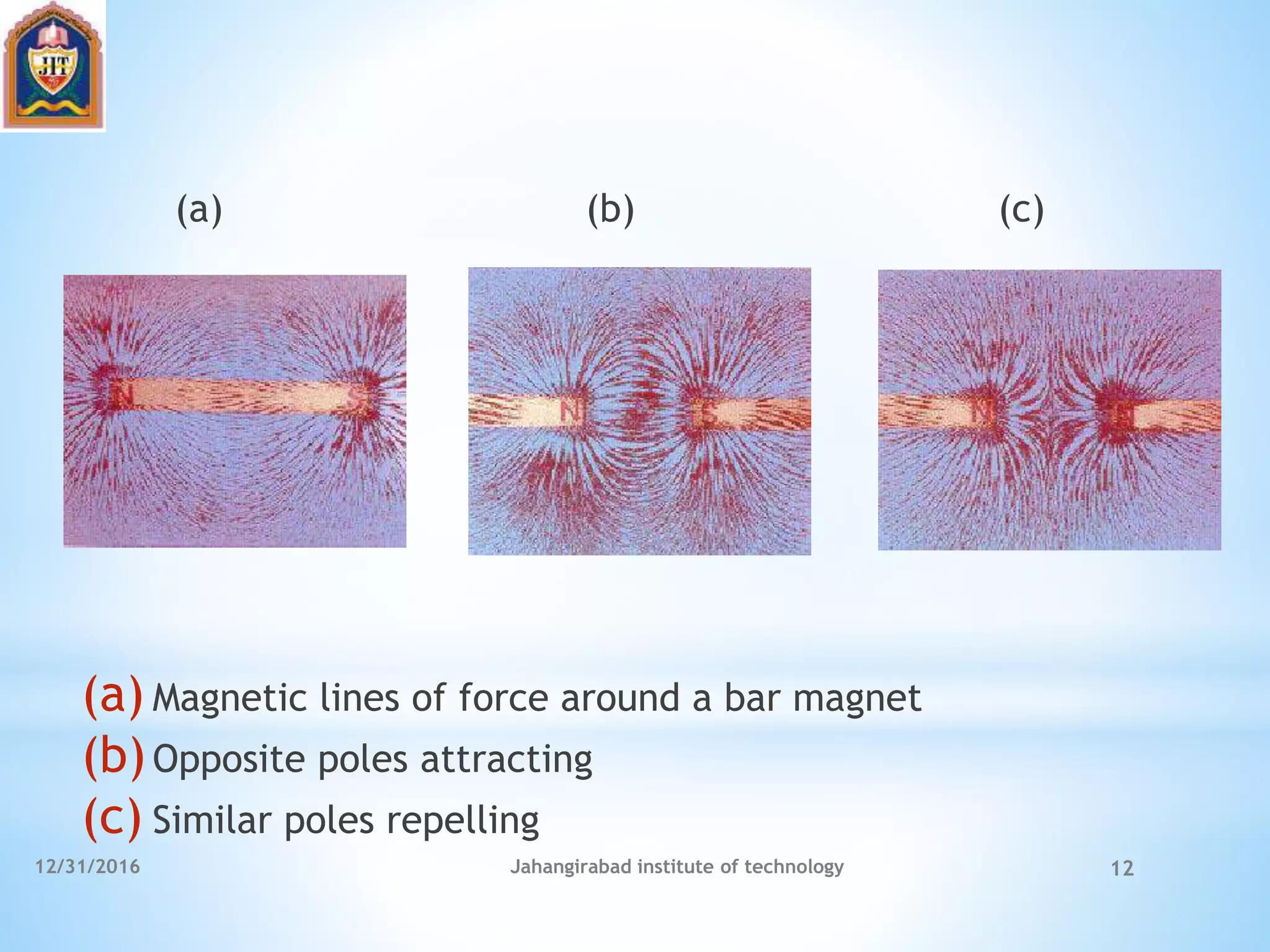

The document discusses liquid penetrant inspection techniques. It describes the characteristics and types of penetrants used, including fluorescent and visible penetrants. It explains how penetrants are classified based on their removal method and sensitivity level. The roles of developers in pulling penetrant from defects are also outlined. Classification methods for developers are provided. Overall, the document provides details on the materials and processes used in liquid penetrant inspection.