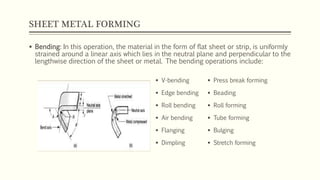

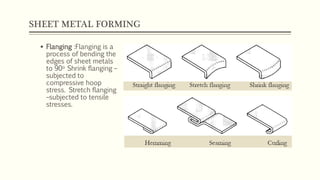

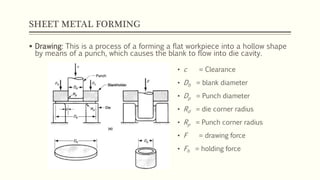

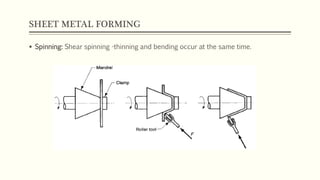

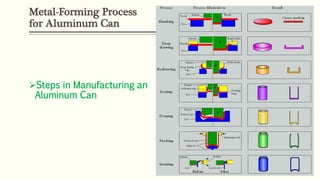

This document discusses sheet metal forming processes. Sheet metal forming takes a flat sheet of metal and uses mechanical forces to alter its shape. There are two main categories of sheet metal operations on a press: shearing/cutting operations and forming operations. Shearing operations like punching, blanking, and notching stress the metal beyond its strength limit. Forming operations like bending, drawing, spinning, and flanging mechanically deform the metal into the desired shape without breaking it. An example given is the process used to form aluminum cans.