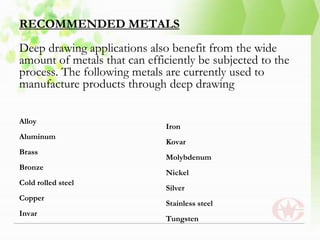

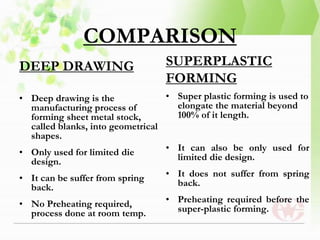

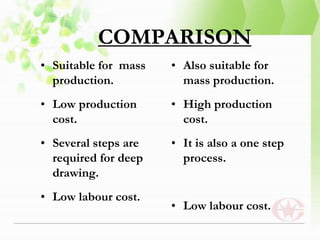

This document provides information about deep drawing and sheet metal forming equipment. It discusses the history and definition of deep drawing, the mechanics and process of drawing, types of deep drawing stations like blanking, drawing, piercing and trimming. It also describes the metal flow during drawing, recommended tool materials, lubrication and cooling methods, common defects, advantages and disadvantages of deep drawing. Different applications of deep drawing in Pakistani industry are highlighted. Comparisons are made between deep drawing and superplastic forming. Finally, various metal forming tools and types of forming dies are explained.