This document discusses various sheet metal processes including cutting, forming, bending, drawing, and stretching operations. Some key points:

1. Sheet metal work involves forming metal sheets 3-5mm thick into parts through cutting, forming, and joining processes.

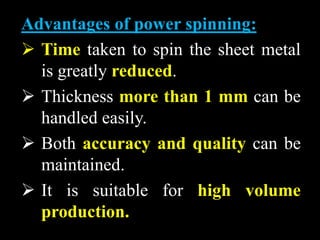

2. Common forming operations include bending, drawing, stamping, spinning, and stretching. Cutting operations include blanking, punching, and shearing.

3. Bending involves curving sheet metal between a punch and die. Drawing uses a punch to force sheet metal into a die cavity. Stretch forming stresses sheet metal beyond its elastic limit with a forming block.