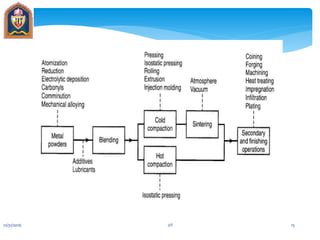

This document discusses various unconventional metal forming processes including high energy rate forming processes like explosive forming, magnetic forming, and electro hydraulic forming. It explains that these processes use large amounts of energy applied very quickly to deform metals. Some advantages are low die costs, easy maintenance of tolerances, and the ability to form difficult metals. The document also covers powder metallurgy and describes the production and applications of parts formed by this process.