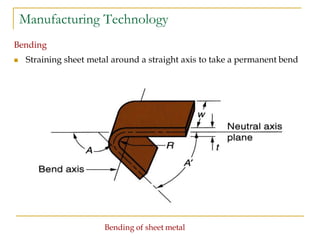

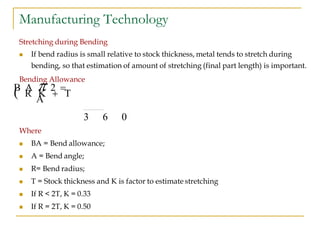

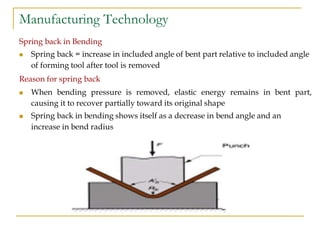

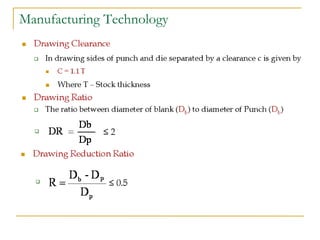

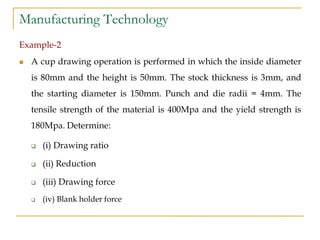

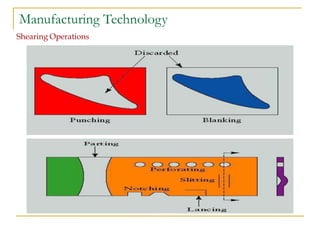

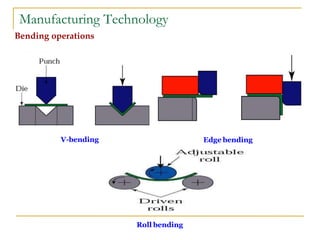

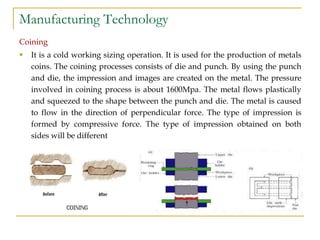

This document provides an overview of sheet metal forming processes. It discusses various sheet metal operations including cutting (shearing) operations like punching, blanking, and trimming as well as forming operations like bending, drawing, and squeezing. Bending operations including V-bending and edge bending are described. Drawing operations for forming hollow shapes are also covered along with squeezing processes like embossing and coining.