The document discusses various methods for manufacturing gears, including:

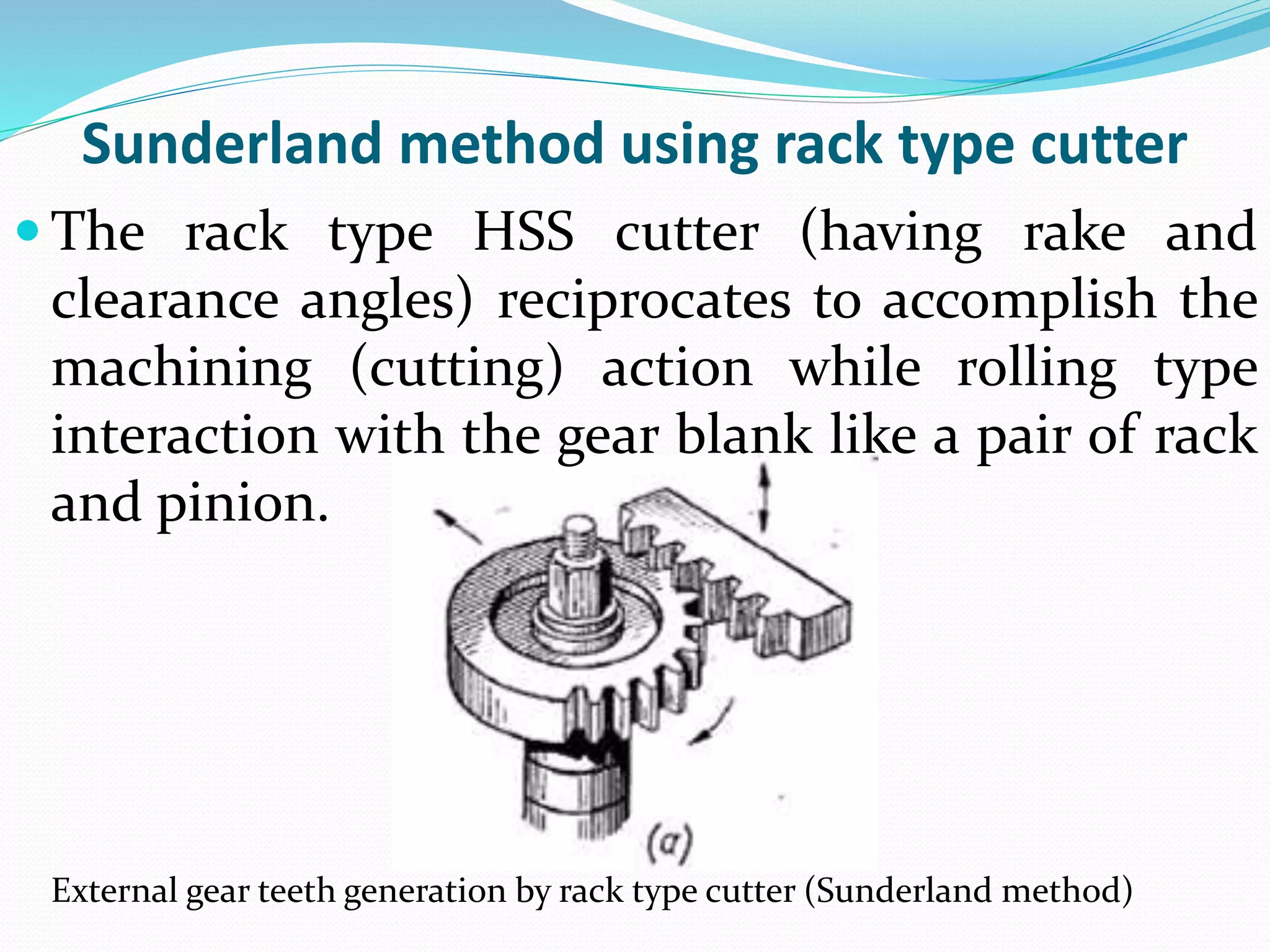

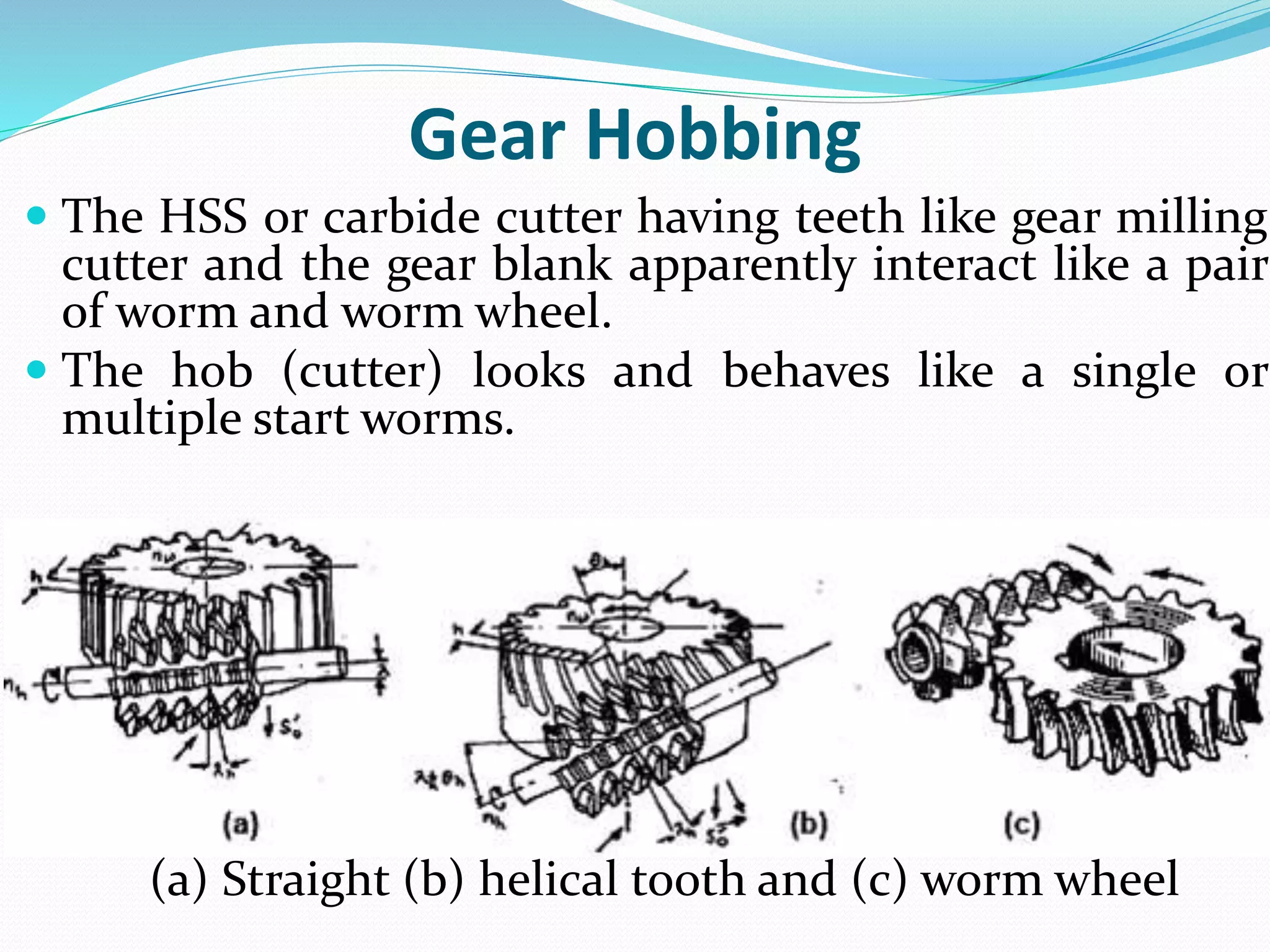

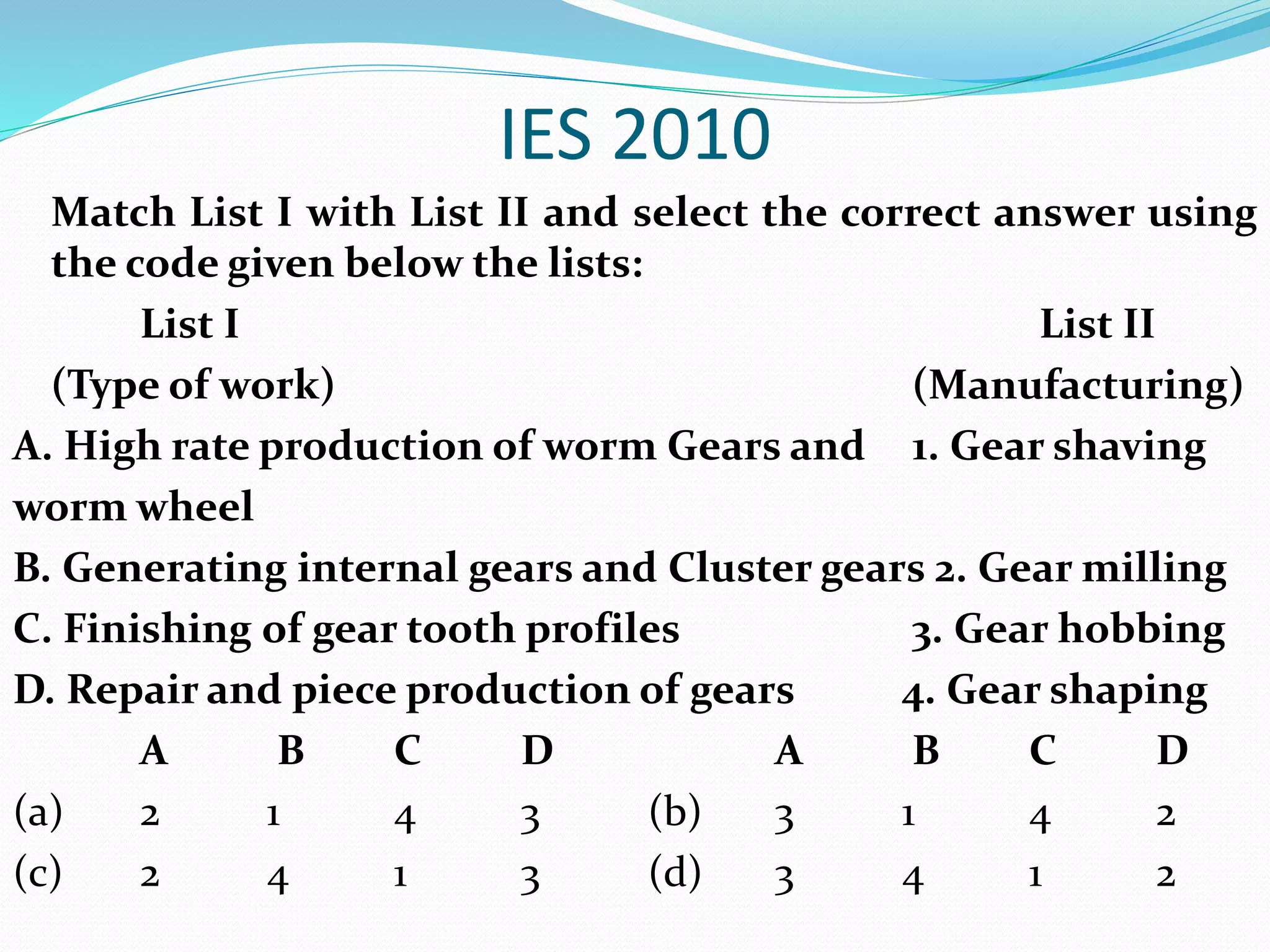

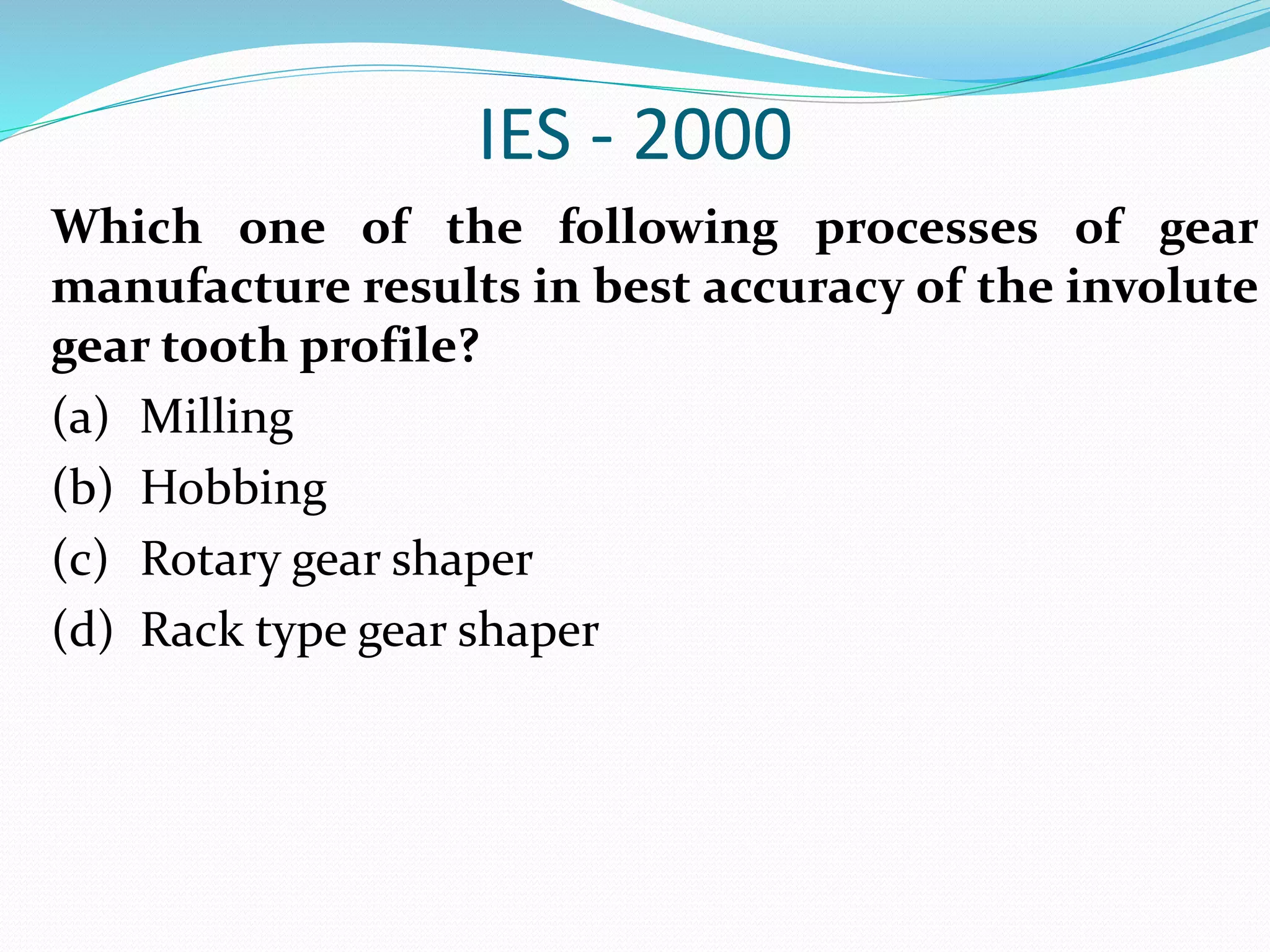

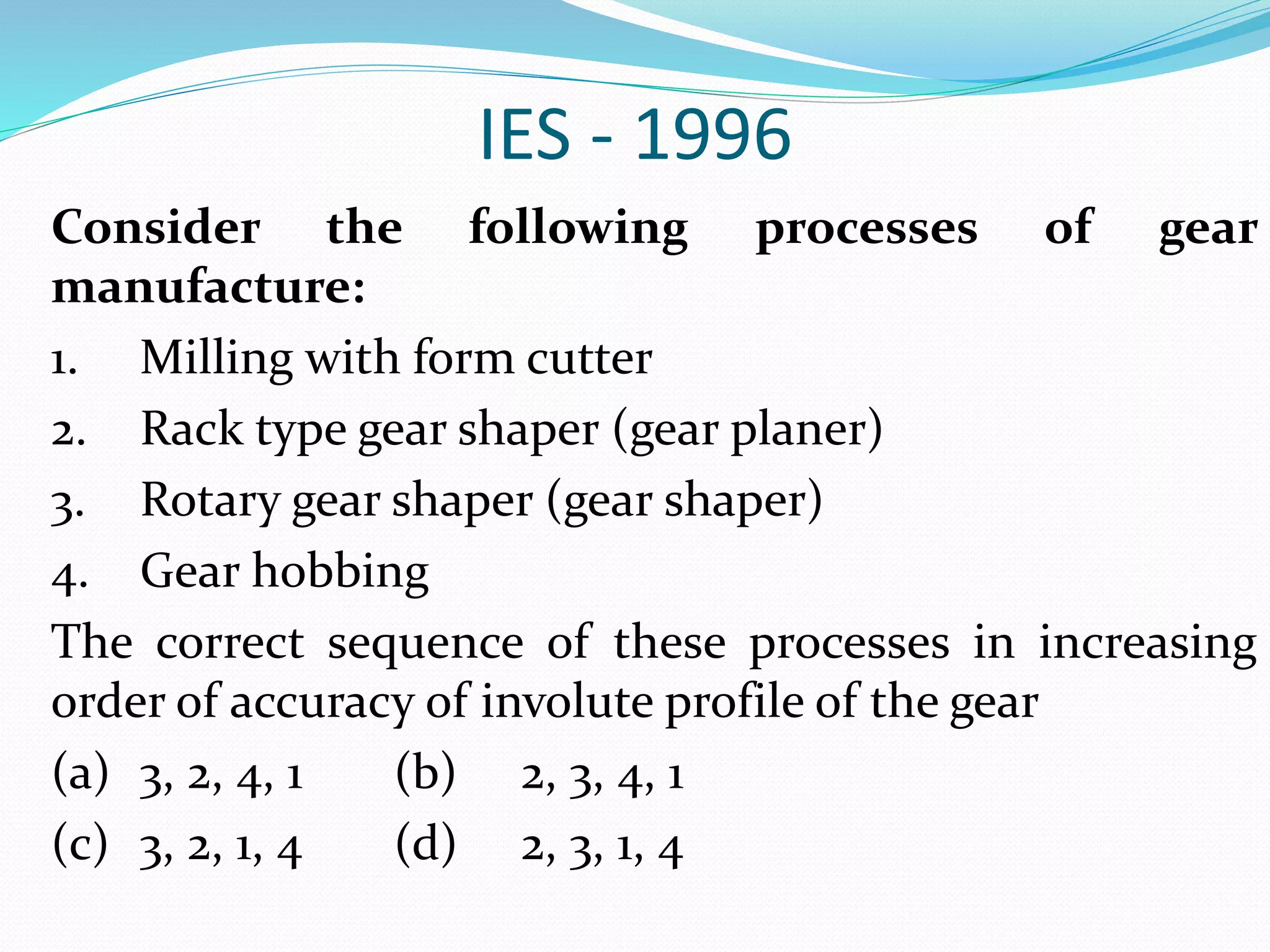

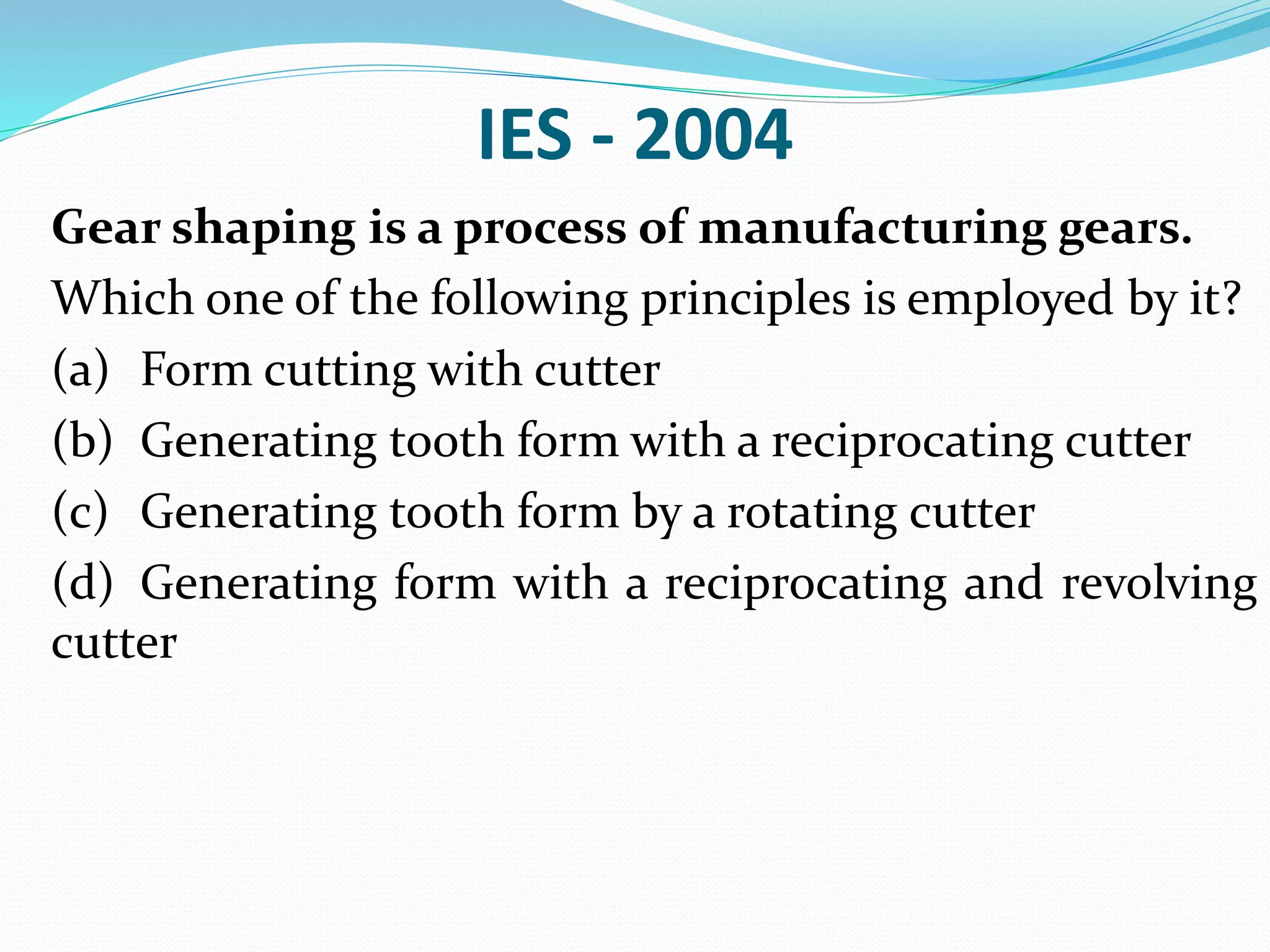

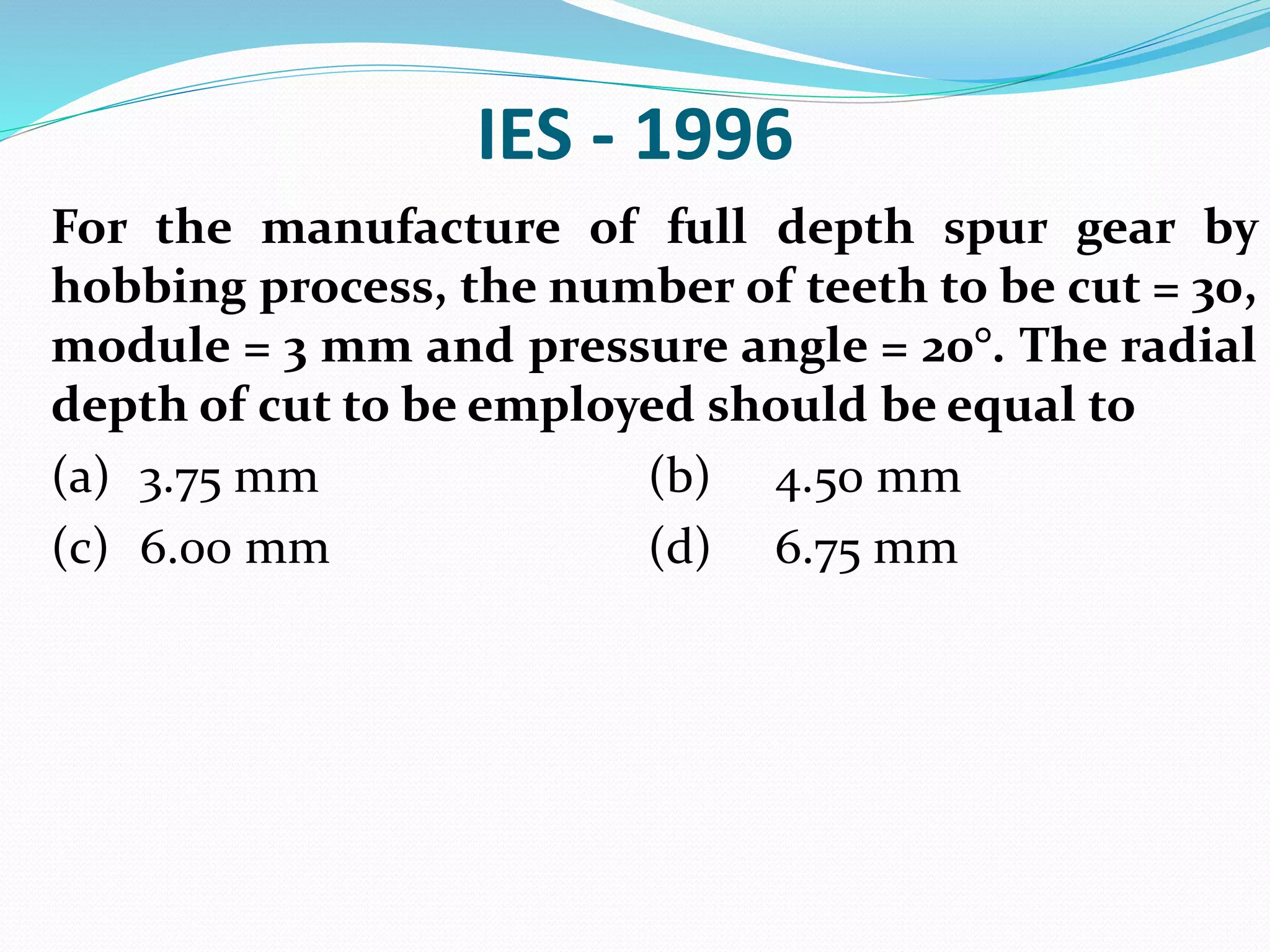

- Gear shaping and hobbing are generating processes that use rotating cutters to form gear teeth profiles. Gear shaping can produce external and internal spur gears with high accuracy, while hobbing is used for external spur gears and worm wheels.

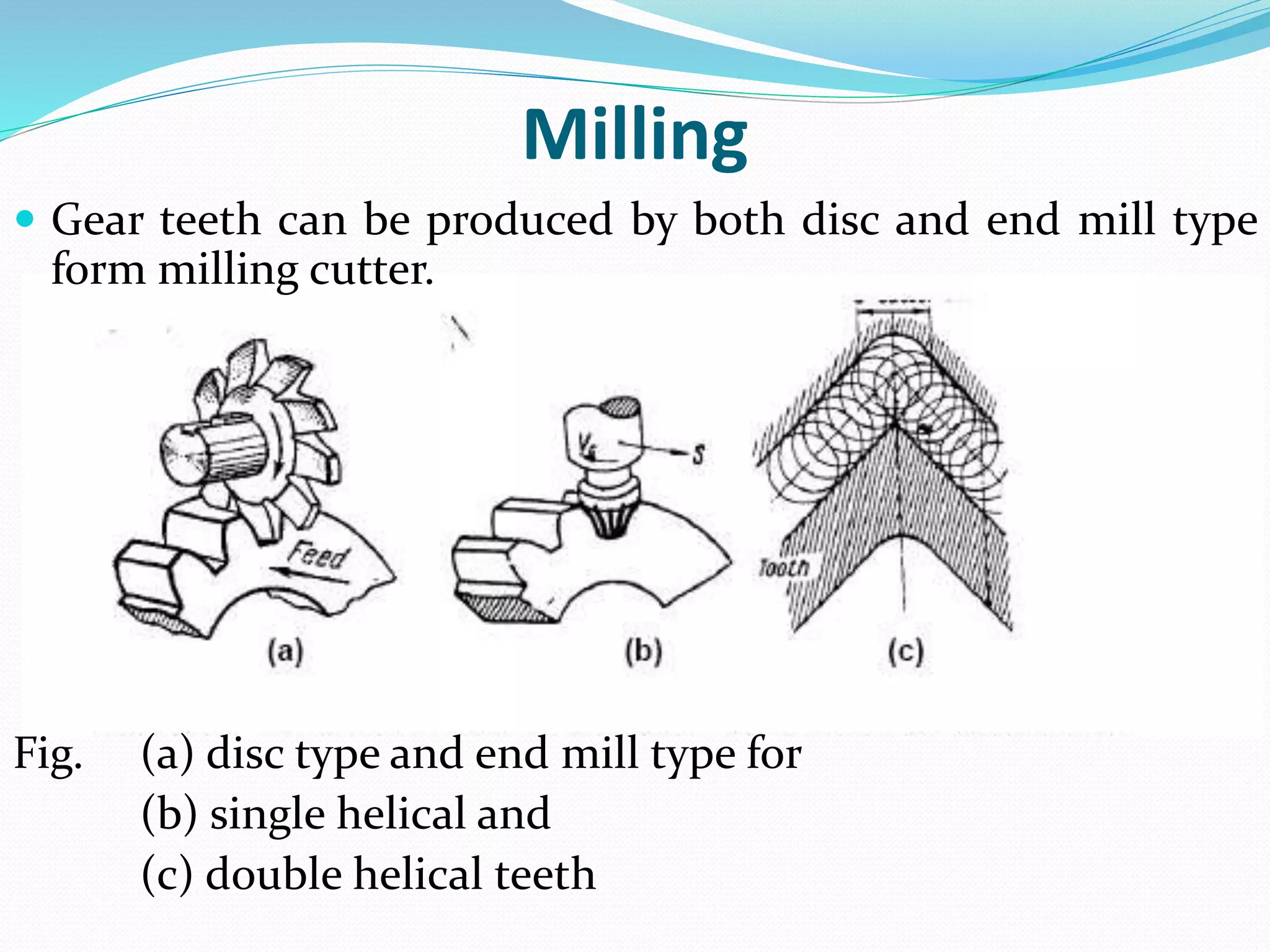

- Gear milling uses form cutters but requires indexing after each tooth, resulting in lower productivity and accuracy than generating processes.

- Other methods discussed include broaching, rolling, powder metallurgy, casting, and machining smaller gears using EDM or broaching. Finishing processes like grinding, lapping, and burnishing are used to improve gear properties.