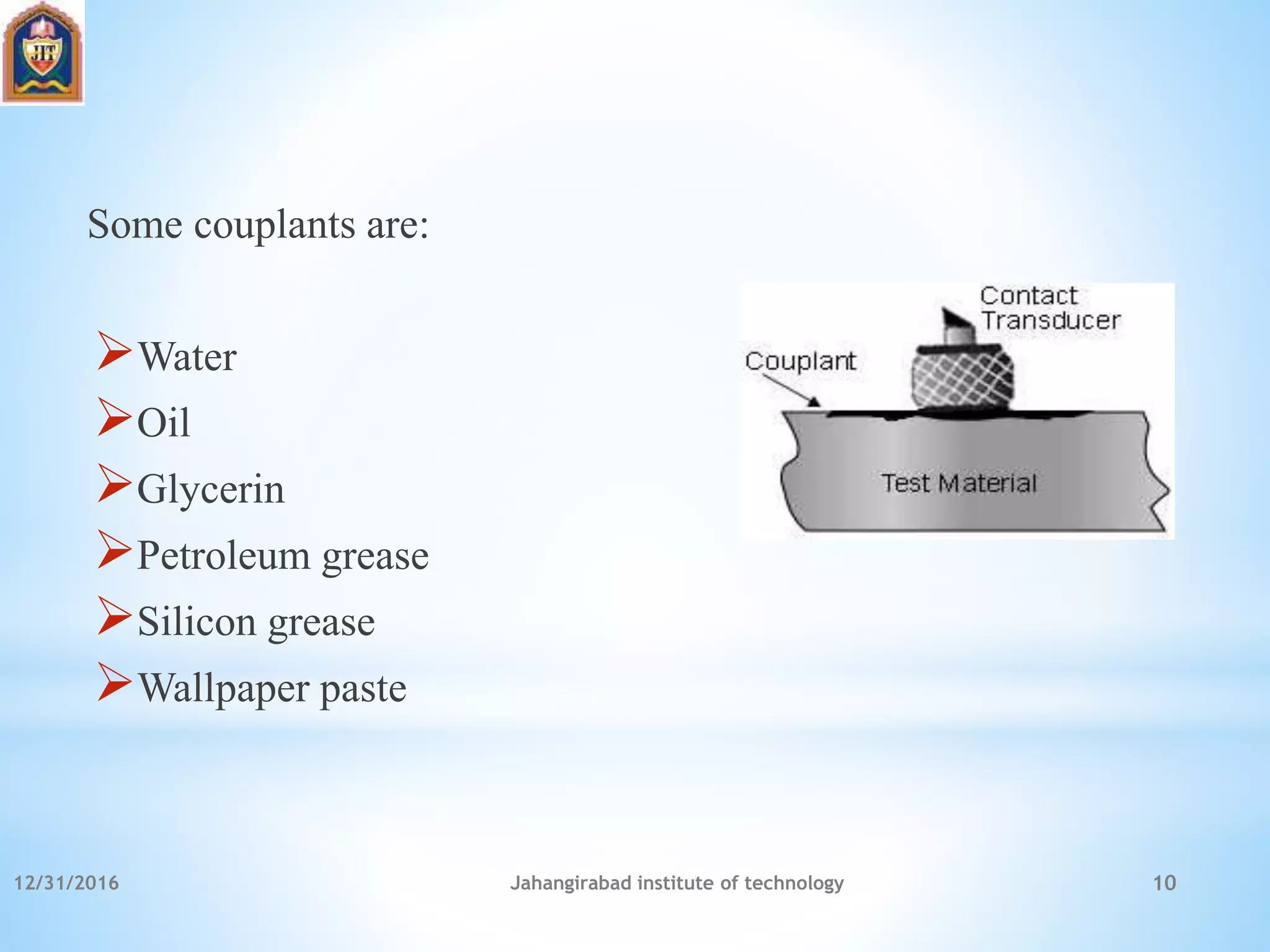

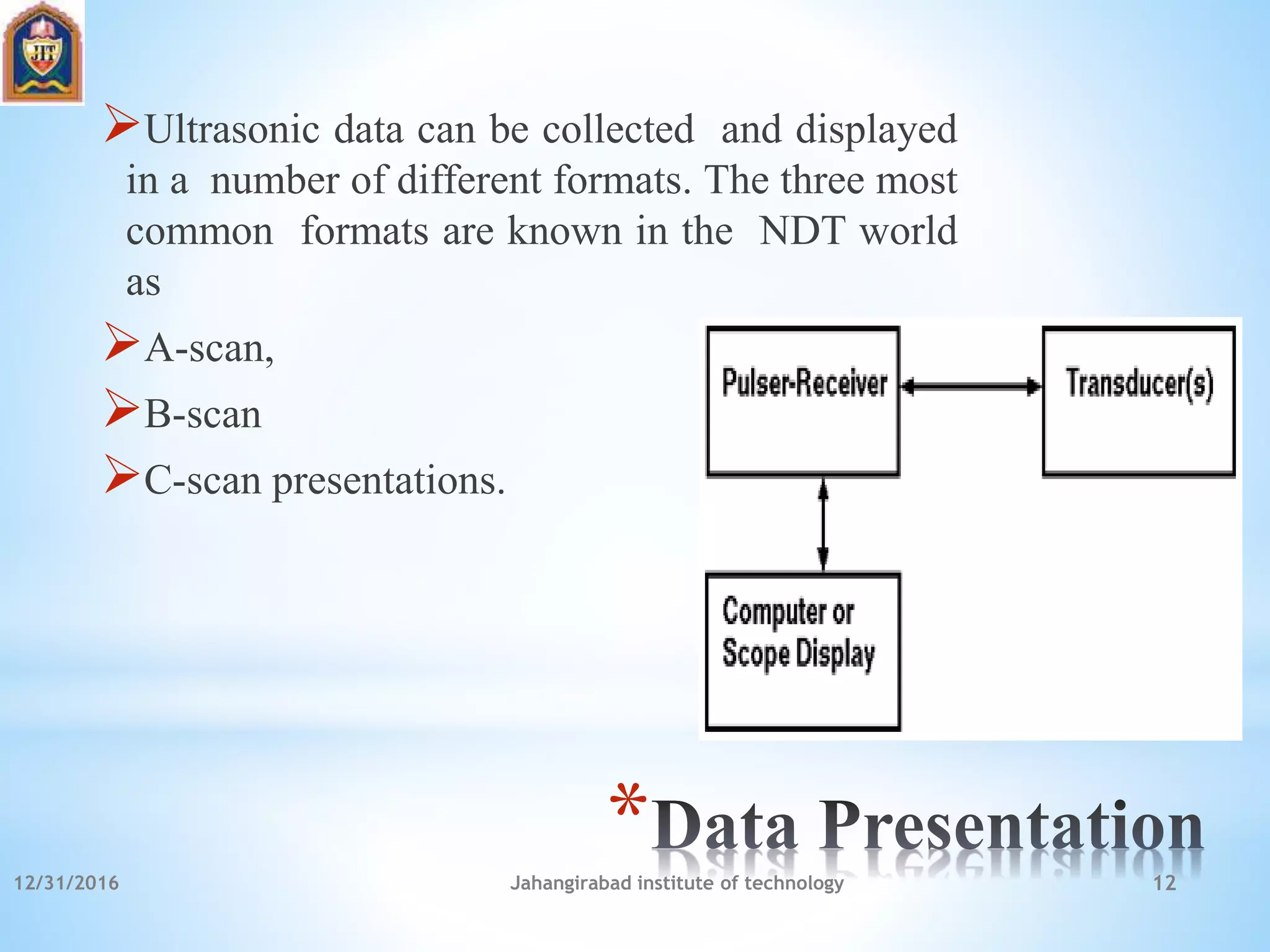

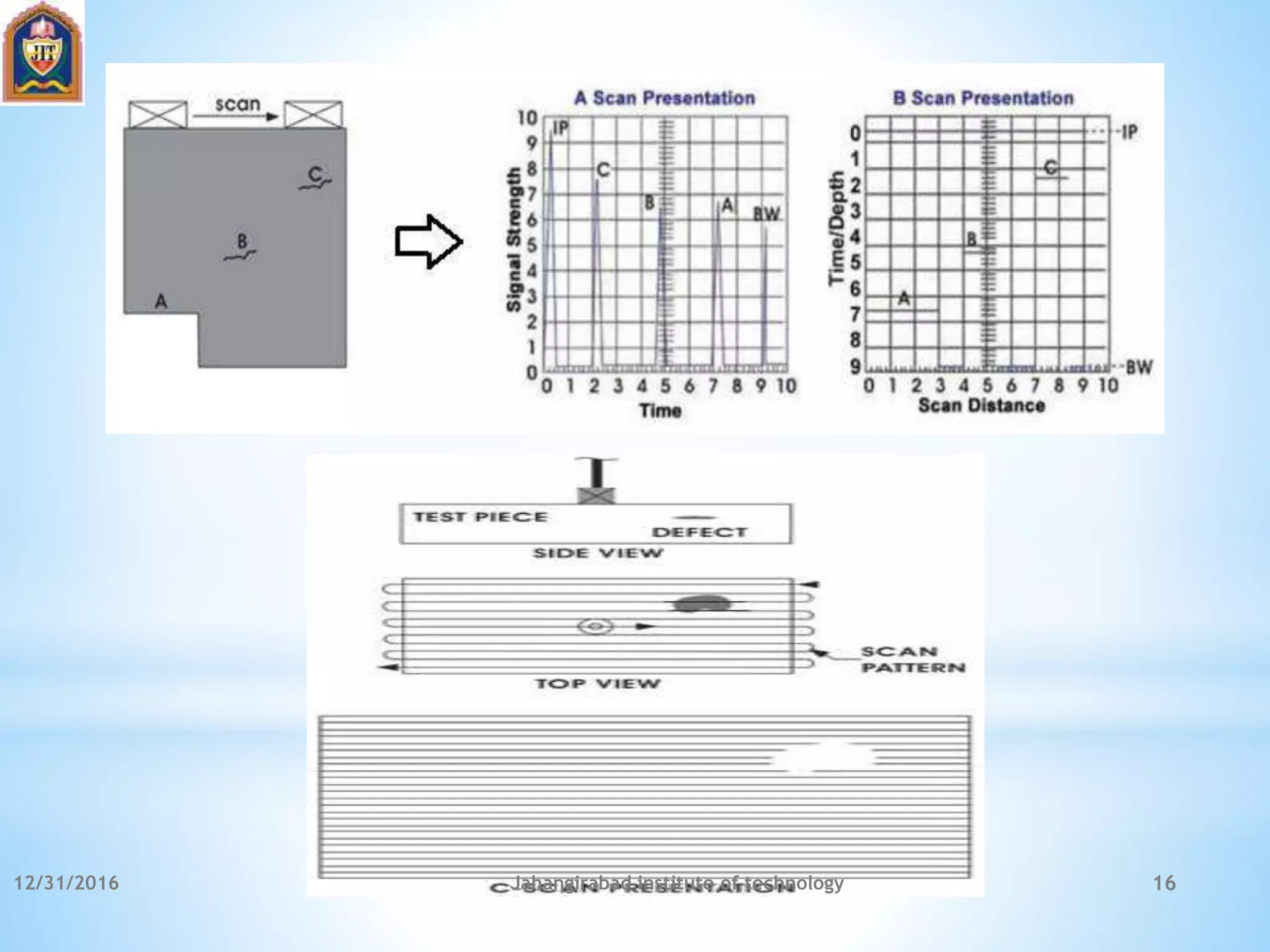

This document discusses ultrasonic testing, which uses ultrasonic waves to detect flaws in materials. It describes how ultrasonic waves are reflected by changes in the material, allowing flaws to be detected. It discusses the different types of ultrasonic waves and testing methods, including pulse echo, through transmission, and resonance. It also covers transducers, couplants, displays of test results, and applications of ultrasonic testing in quality control and materials inspection.