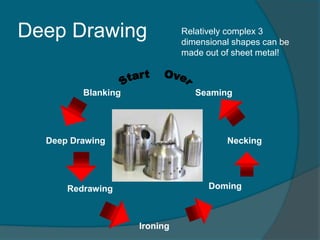

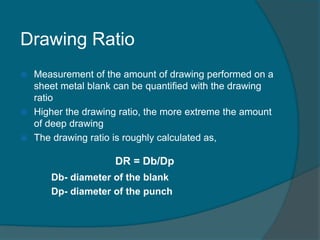

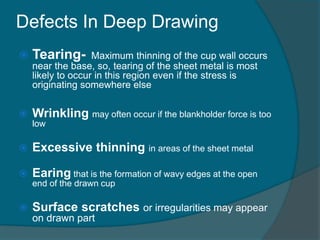

Deep drawing is a metal forming process where a flat sheet is formed into a hollow shape using a punch and die. The sheet is placed over the die opening and held in place by a blank holder. The punch then forces the sheet into the die cavity, forming it into the desired shape. Deep drawing can produce complex 3D shapes from sheet metal and offers advantages like high production rates and consistency. However, defects may occur like tearing, wrinkling, thinning, or earing if the process is not controlled properly.