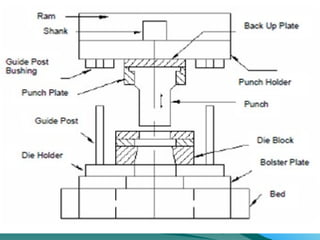

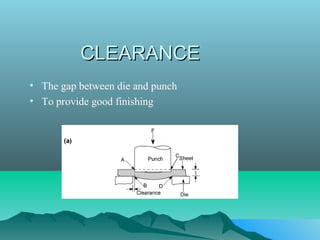

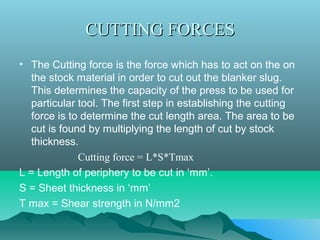

The document provides a comprehensive overview of sheet metal works, detailing the fundamentals of press working, terminology, operations, and types of dies used in manufacturing. It explains processes such as cutting and forming, including techniques like bending and deep drawing, while also covering the mechanical aspects of press machinery and cutting forces involved. Additionally, it classifies dies based on their operation type and outlines methods for effectively reducing cutting force.