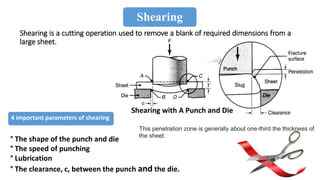

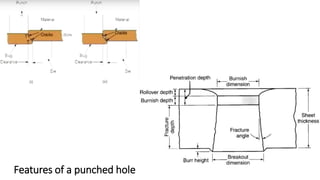

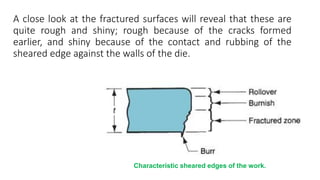

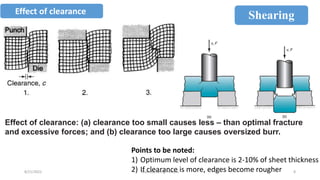

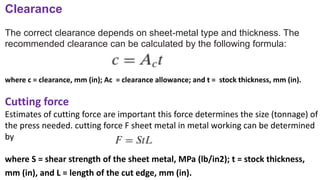

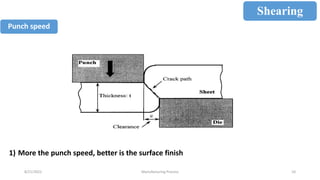

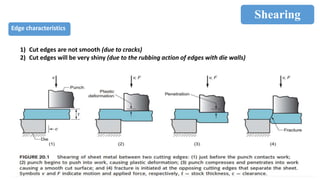

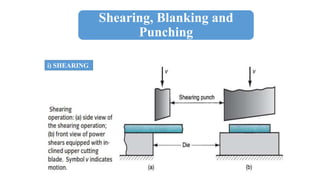

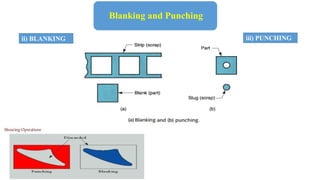

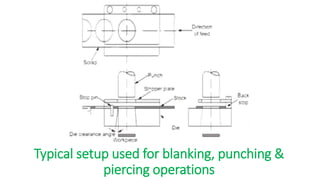

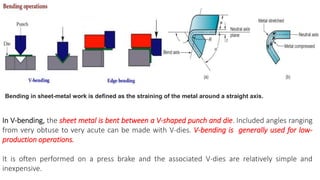

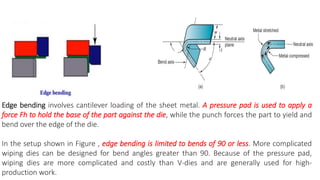

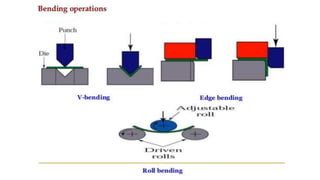

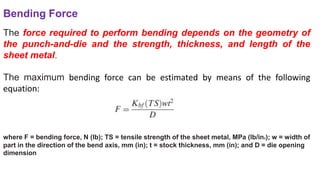

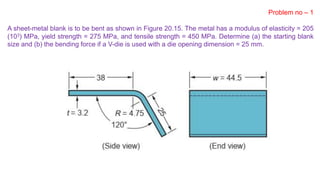

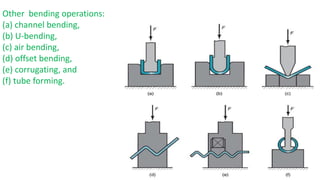

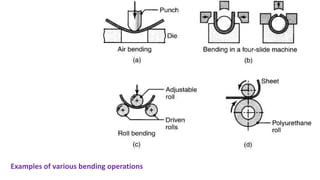

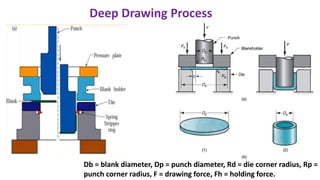

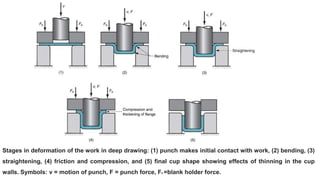

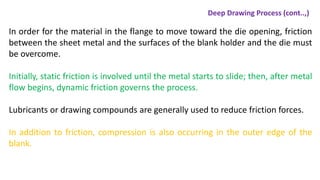

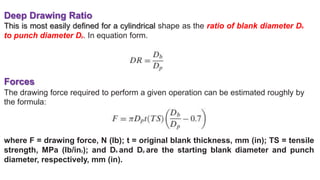

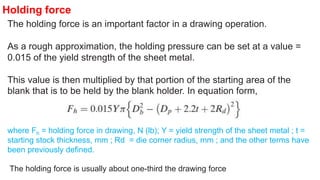

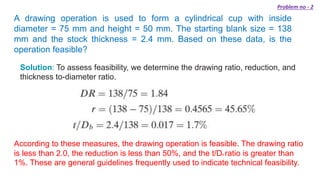

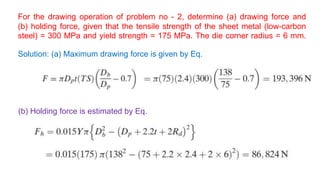

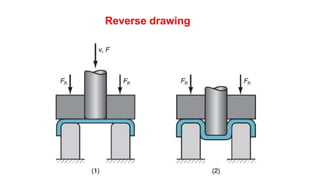

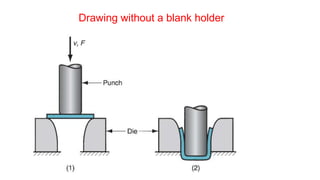

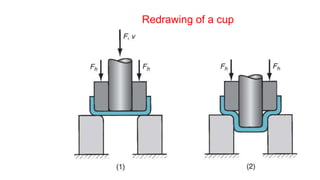

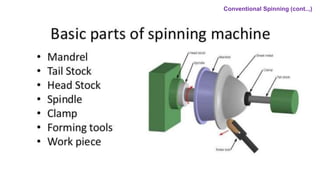

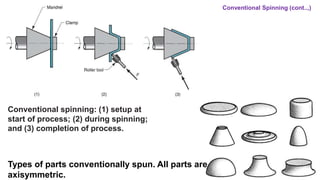

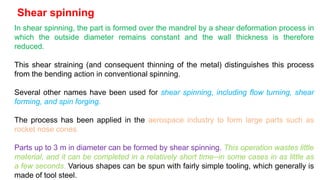

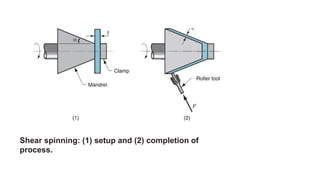

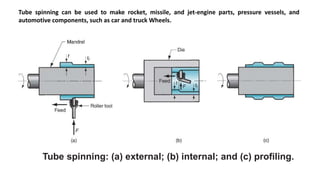

The document discusses various sheet metal processes including shearing, punching, blanking, bending, drawing, spinning, and forming. It provides details on each process such as the basic setup, how it works, applications, advantages, and equations to calculate forces required. Key points covered include how shearing produces rough cut edges, the importance of proper clearance in punching, the stages of deep drawing including thinning, and how spinning can form axisymmetric shapes through localized deformation.