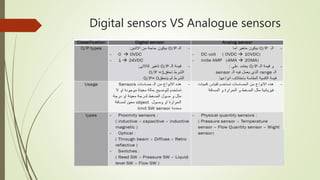

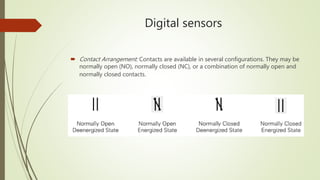

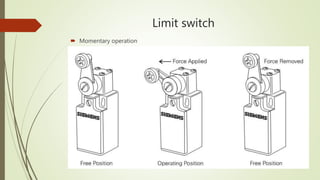

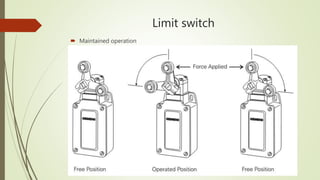

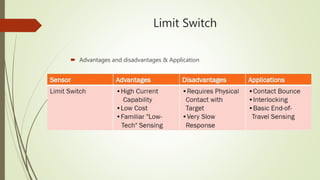

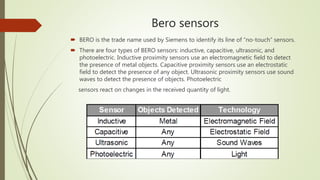

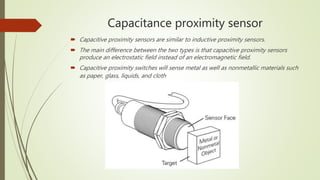

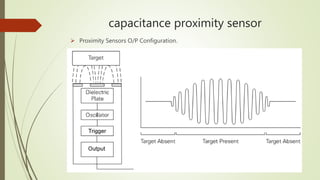

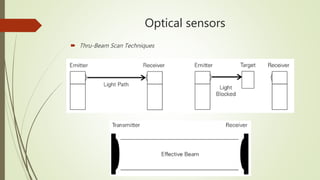

There are many different types of sensors that can be used for various purposes based on their operating principles and outputs. Sensors can sense physical quantities like pressure, temperature, distance and detect properties of materials. They are classified according to their power source, output signal and detection method. Common sensor types include optical sensors, proximity sensors, switches, and those that detect specific physical quantities. Proximity sensors include inductive, capacitive and ultrasonic varieties. Limit switches can be configured for momentary or maintained operation. Digital and analog sensors provide different output signal types. Application of sensors depends on the sensing requirement.