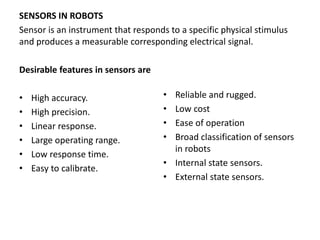

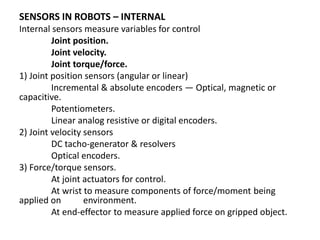

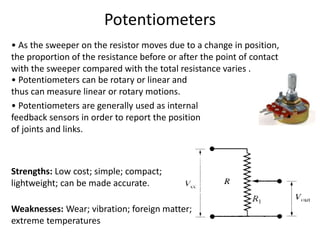

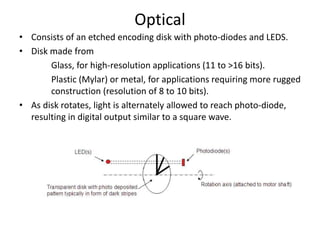

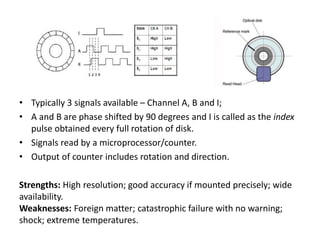

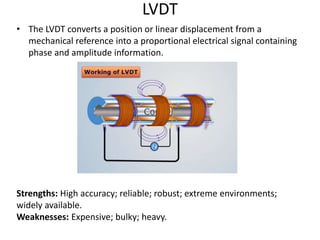

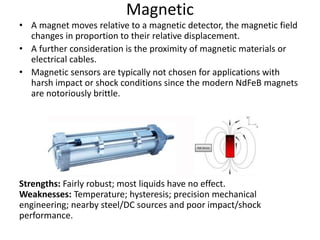

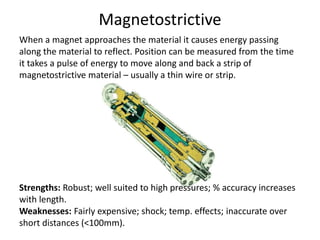

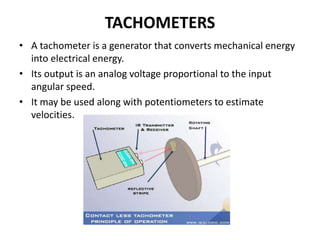

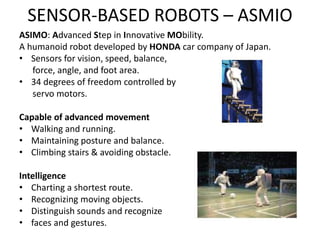

This document provides an overview of sensors used in robots. It discusses that sensors allow robots to perceive their environment and perform tasks reliably. The document then describes various types of internal sensors like position, velocity, force sensors and external sensors like proximity, range finding, color and motion sensors. It provides details on specific position sensors like potentiometers, optical encoders, LVDTs and magnetic sensors. The document also discusses velocity sensors such as encoders and tachometers. Finally, it mentions new developments in sensor technology including MEMS, MOEMS and smart sensors, and provides an example of the humanoid robot ASIMO which utilizes various sensors for functions like vision, balance and intelligence.