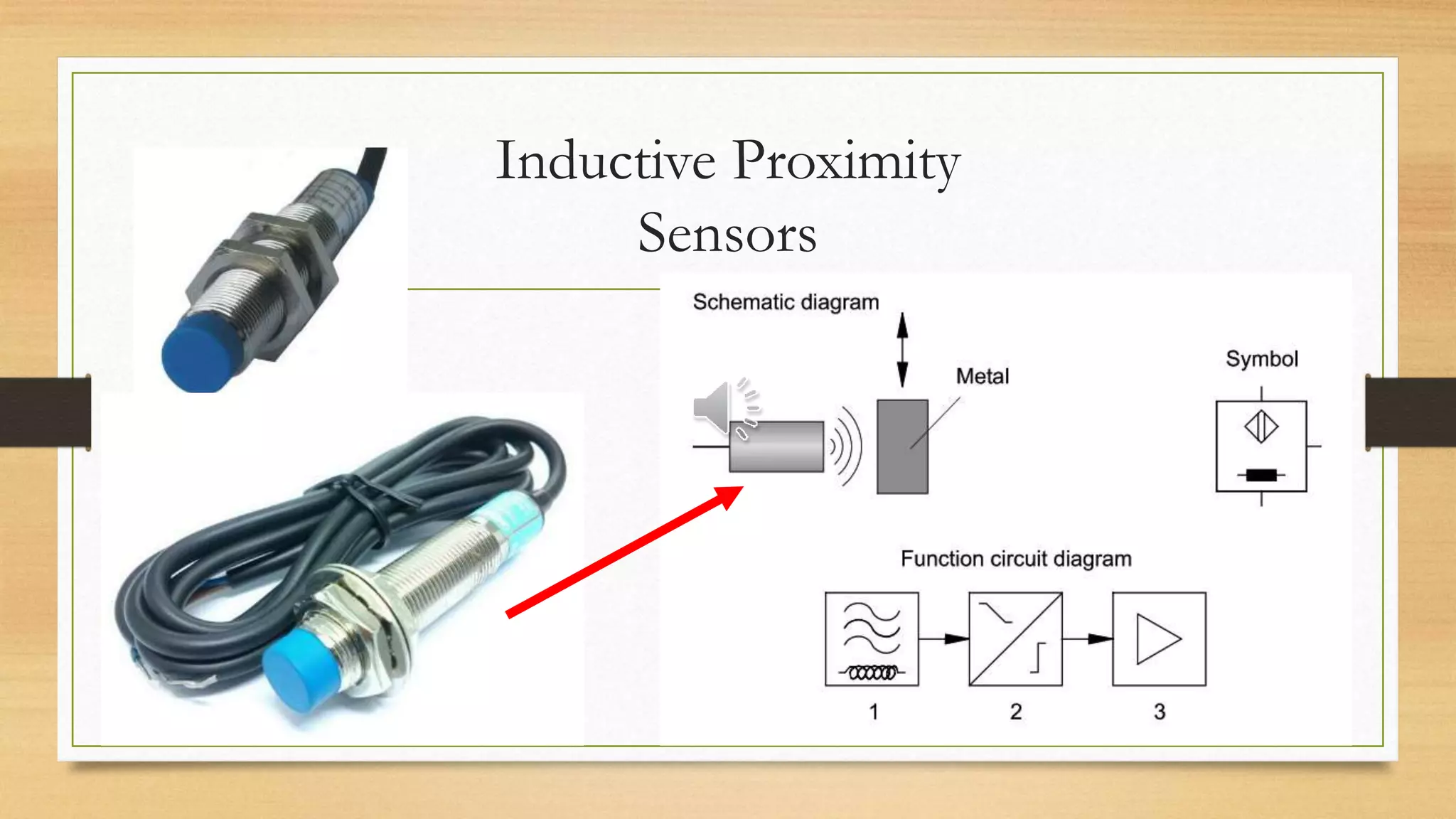

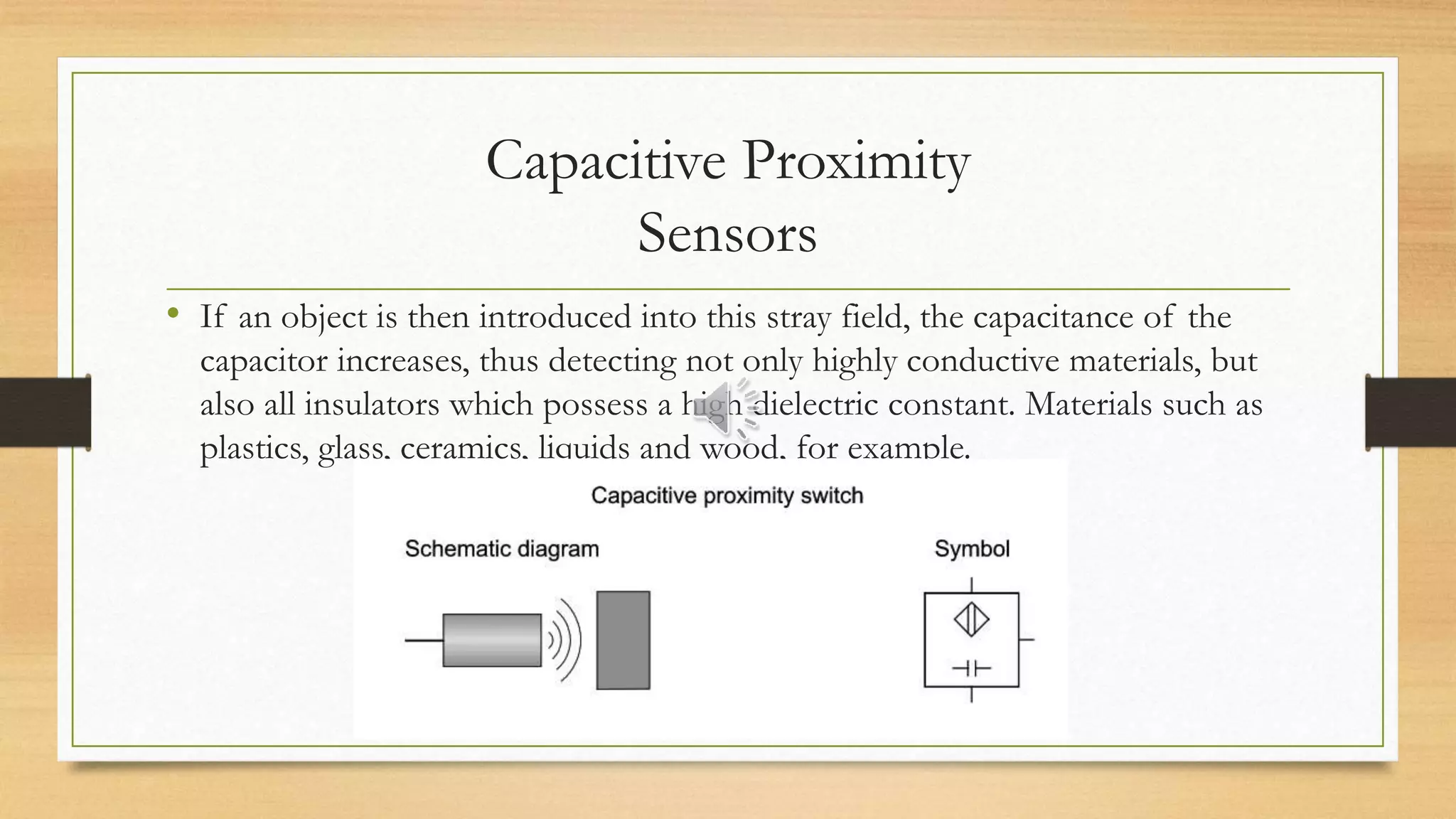

This document discusses different types of proximity sensors, including reed switches, inductive, capacitive, and optical sensors. It provides details on the working principles and characteristics of each. Reed switches use changes in magnetic fields to detect proximity, while inductive sensors detect changes in oscillating circuits from nearby conductive materials. Capacitive sensors measure changes in capacitance from nearby objects, and can detect non-conductive materials. Optical sensors include through-beam, retro-reflective, and diffuse sensors that detect interruptions or reflections of light beams.