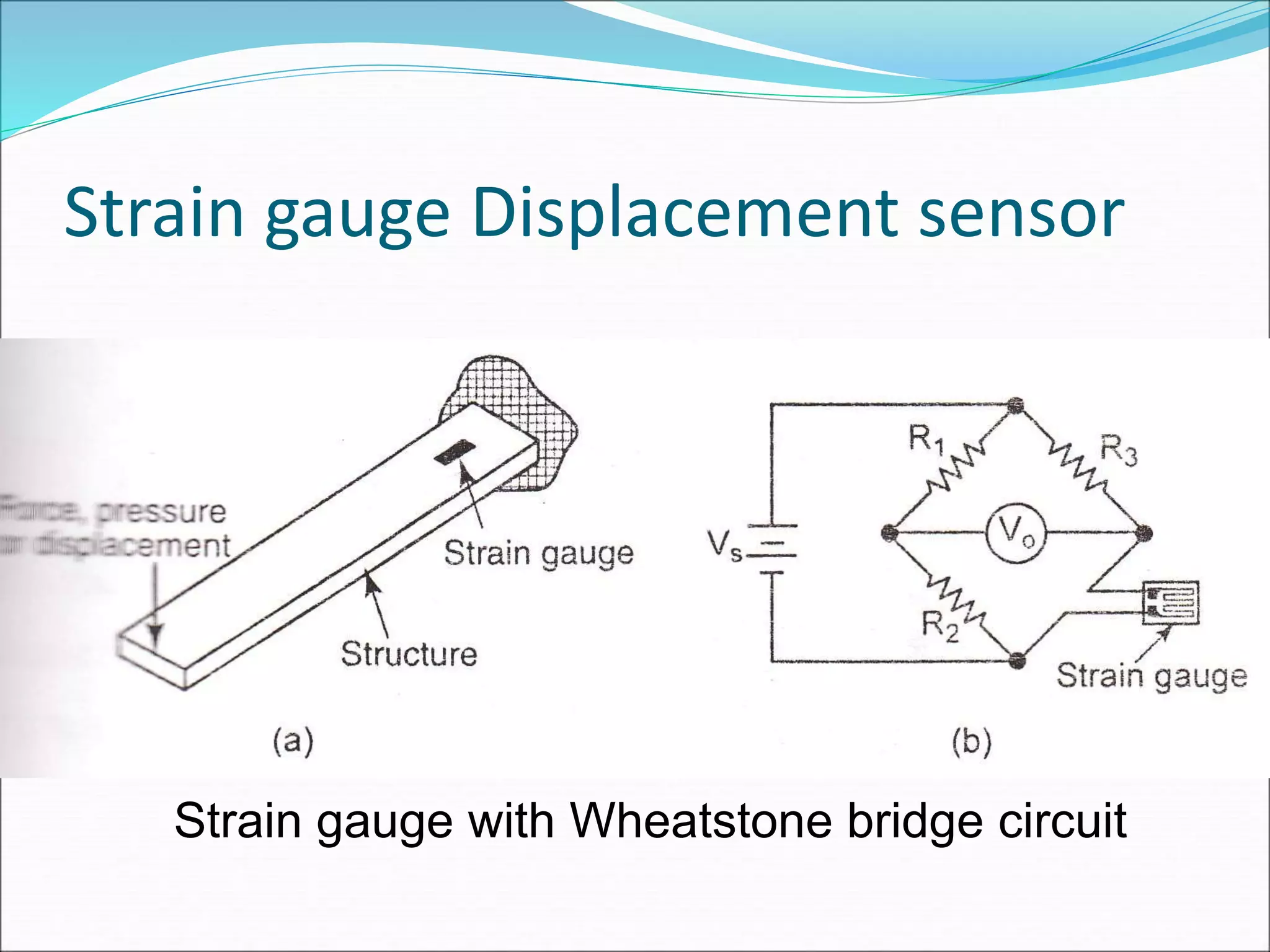

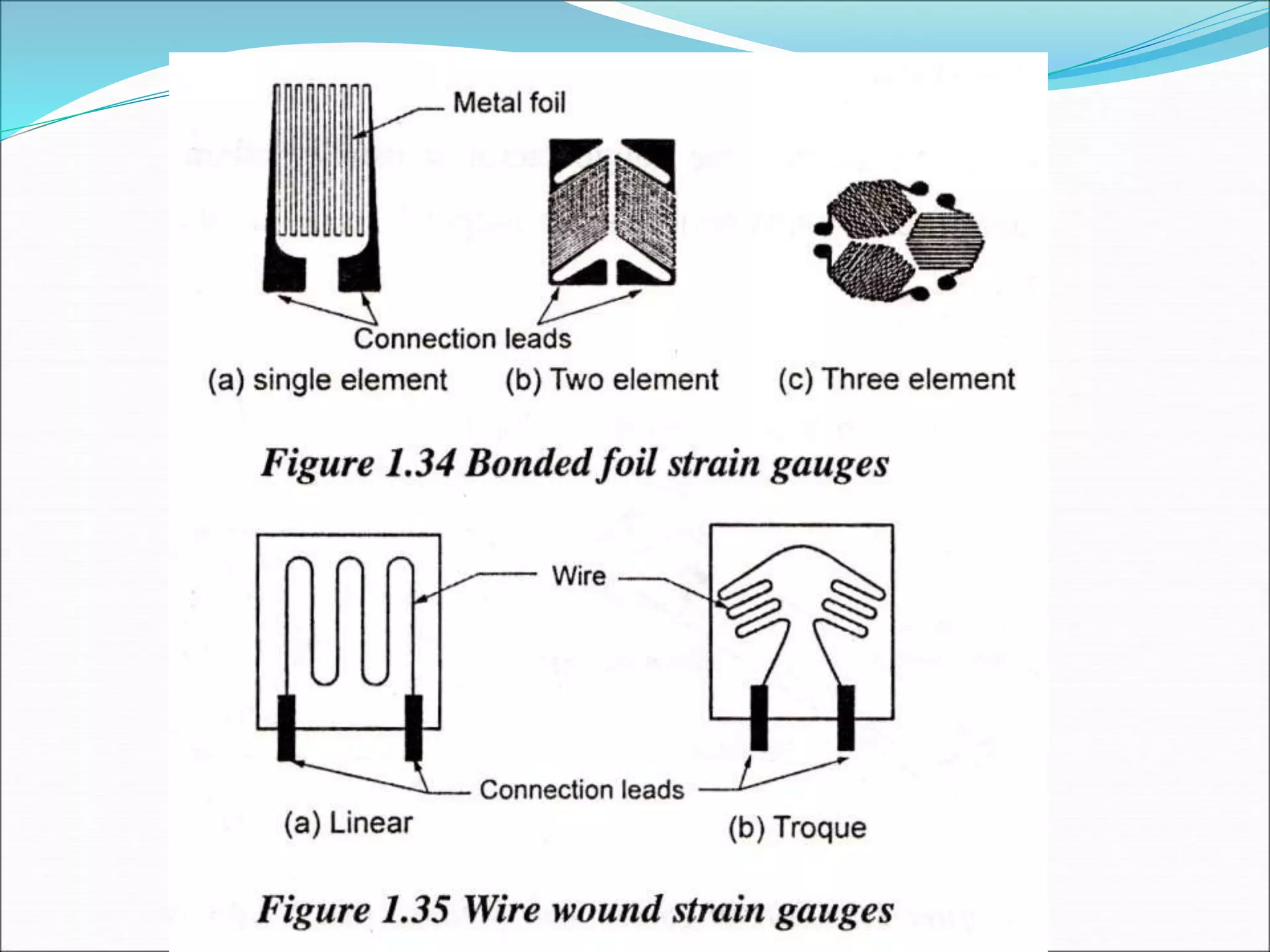

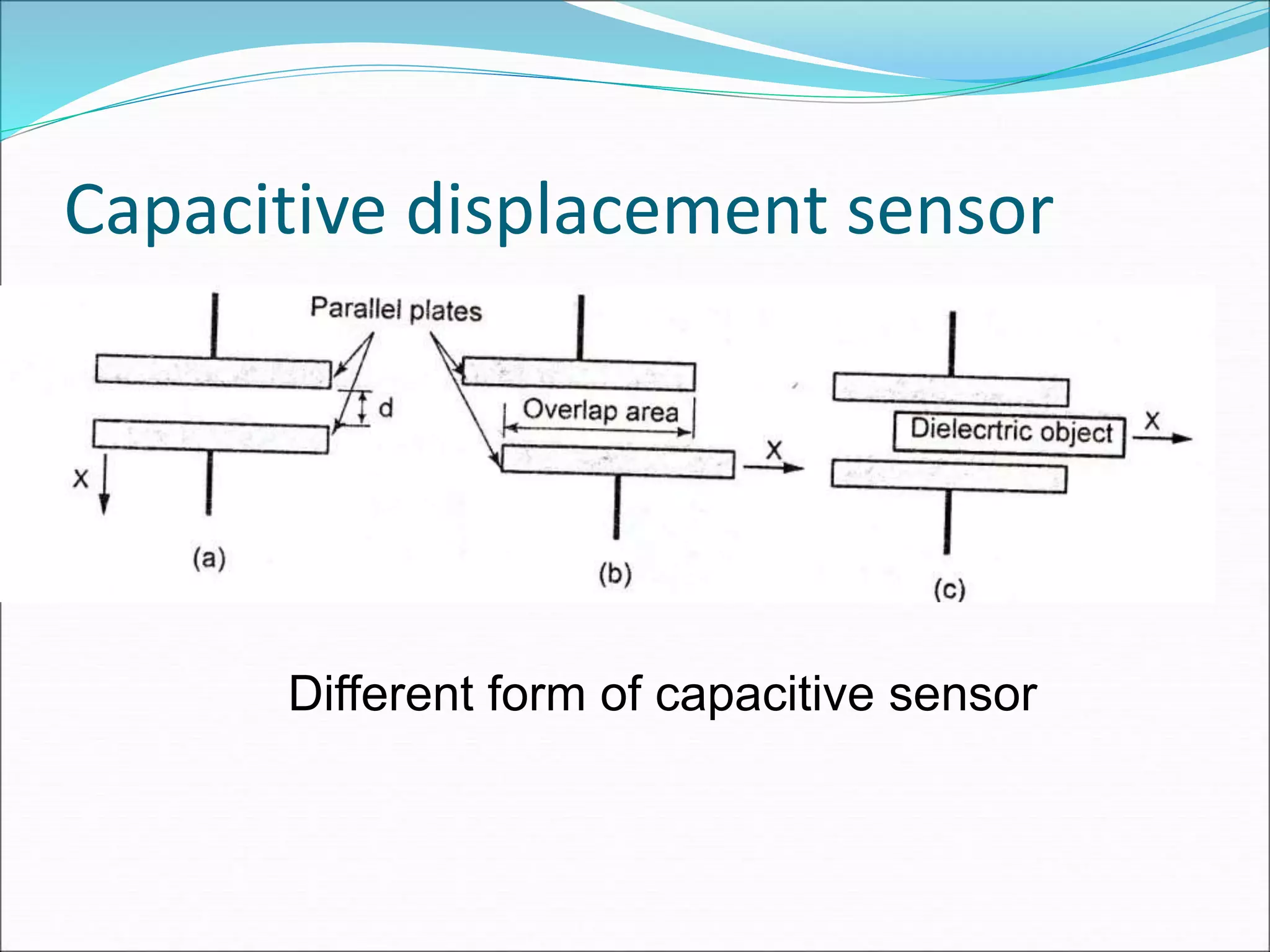

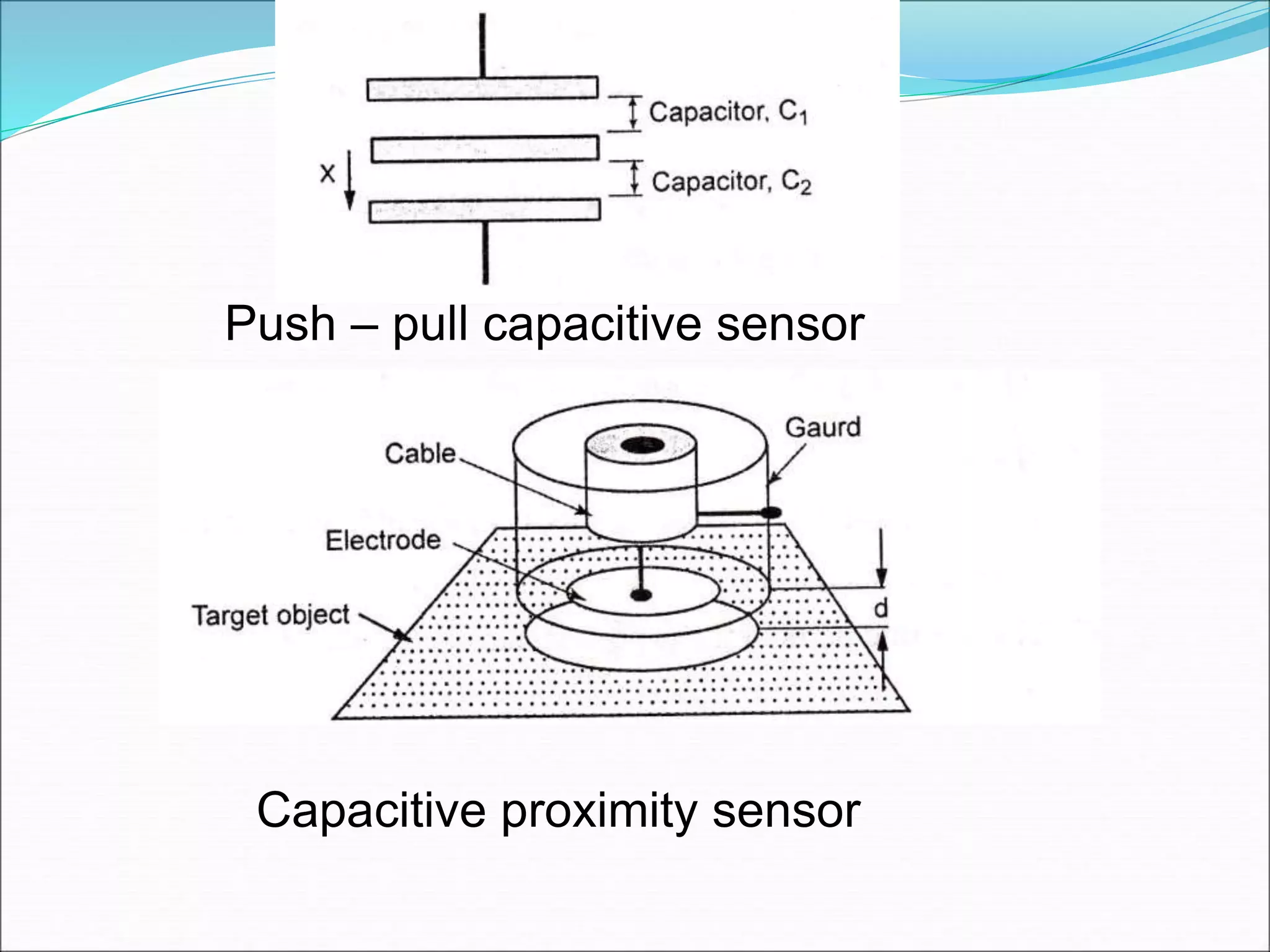

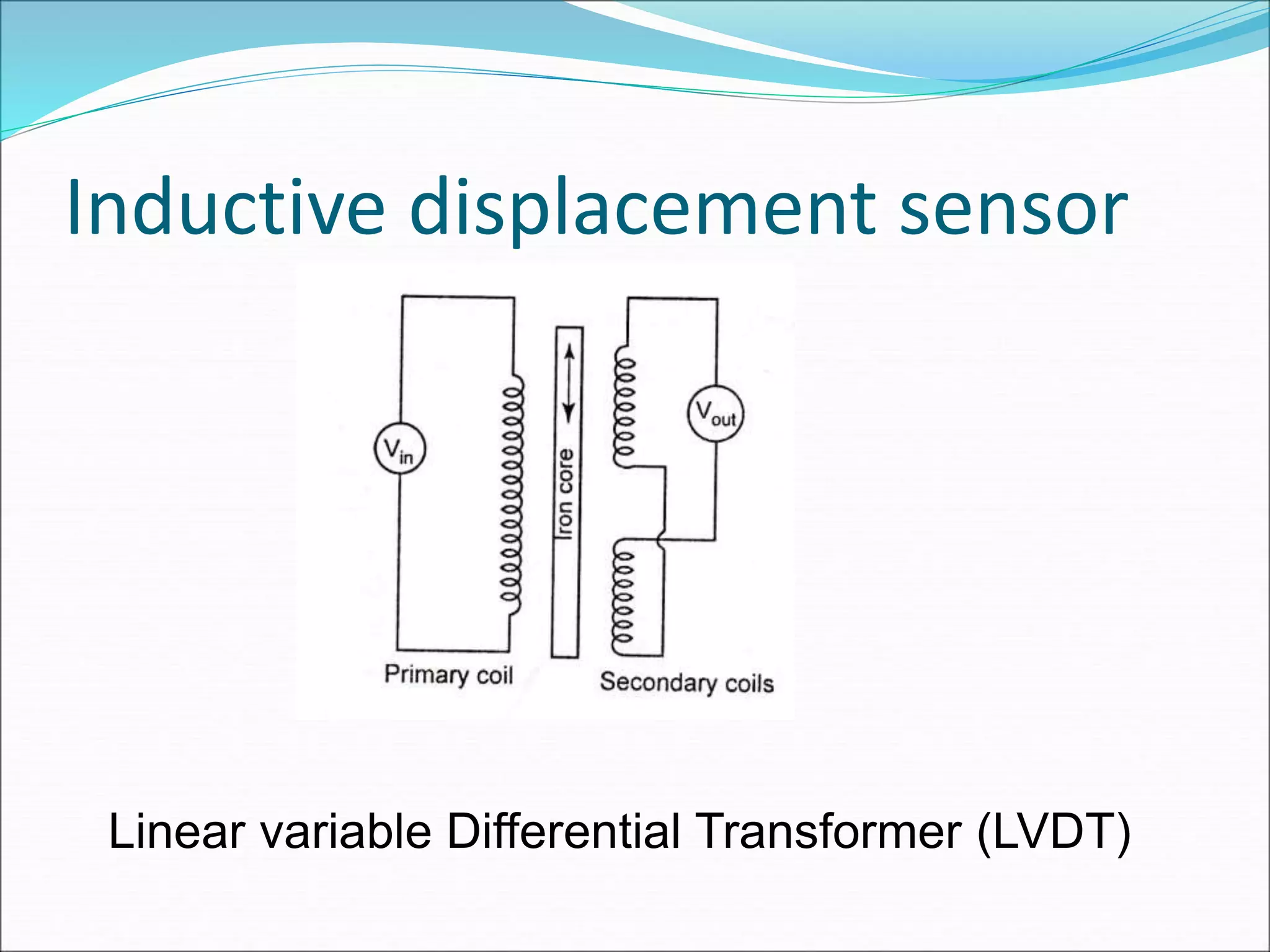

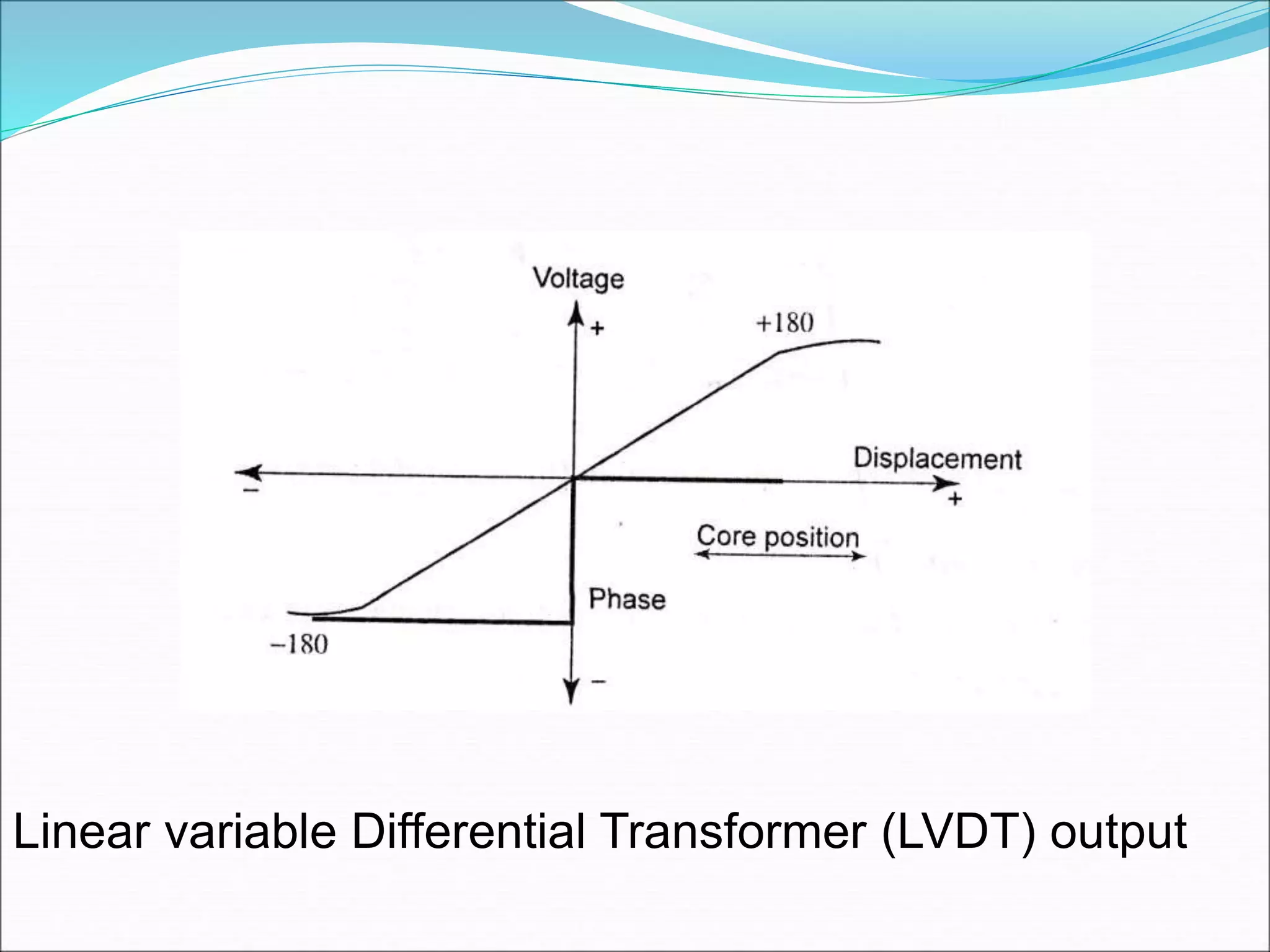

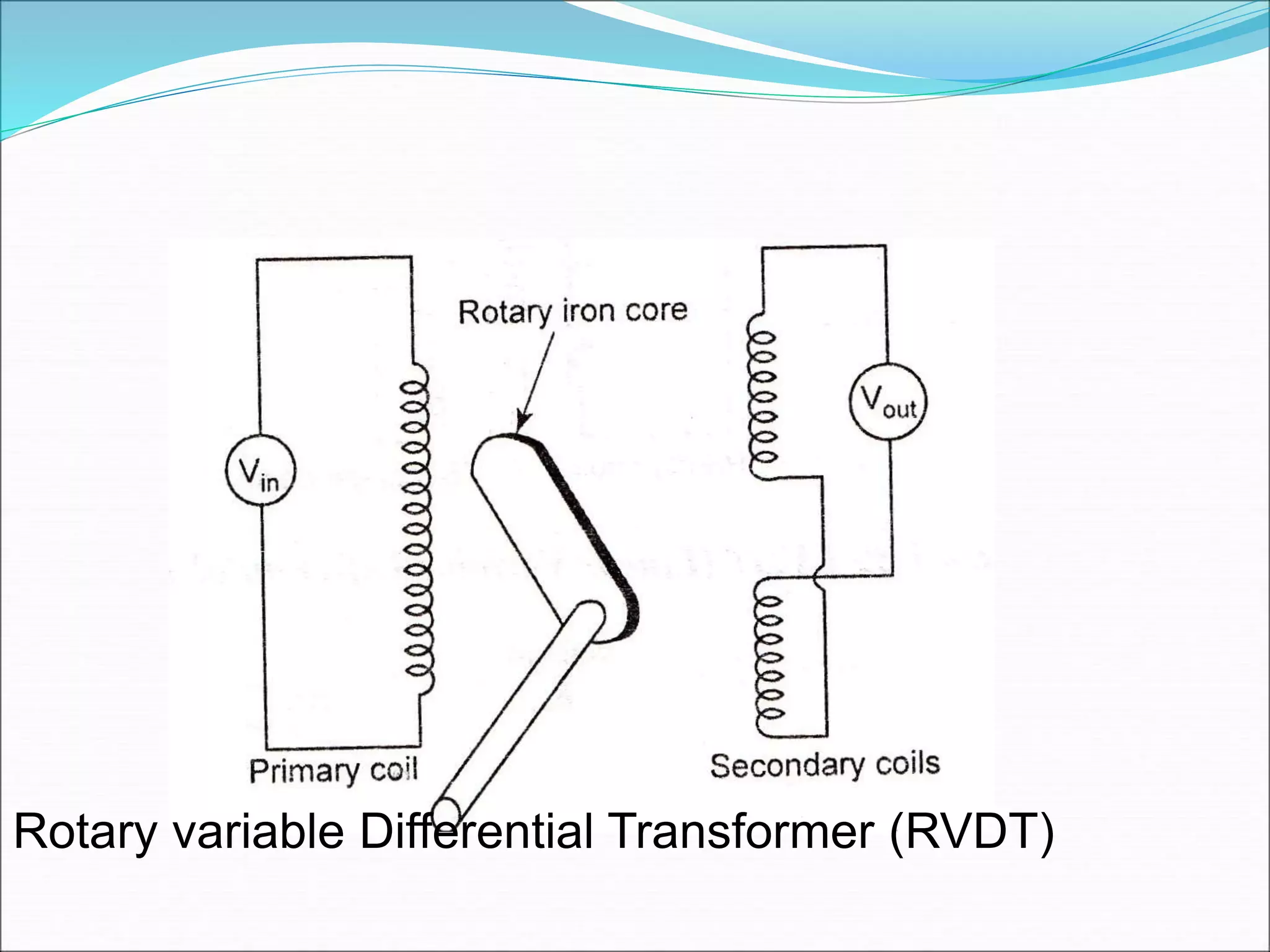

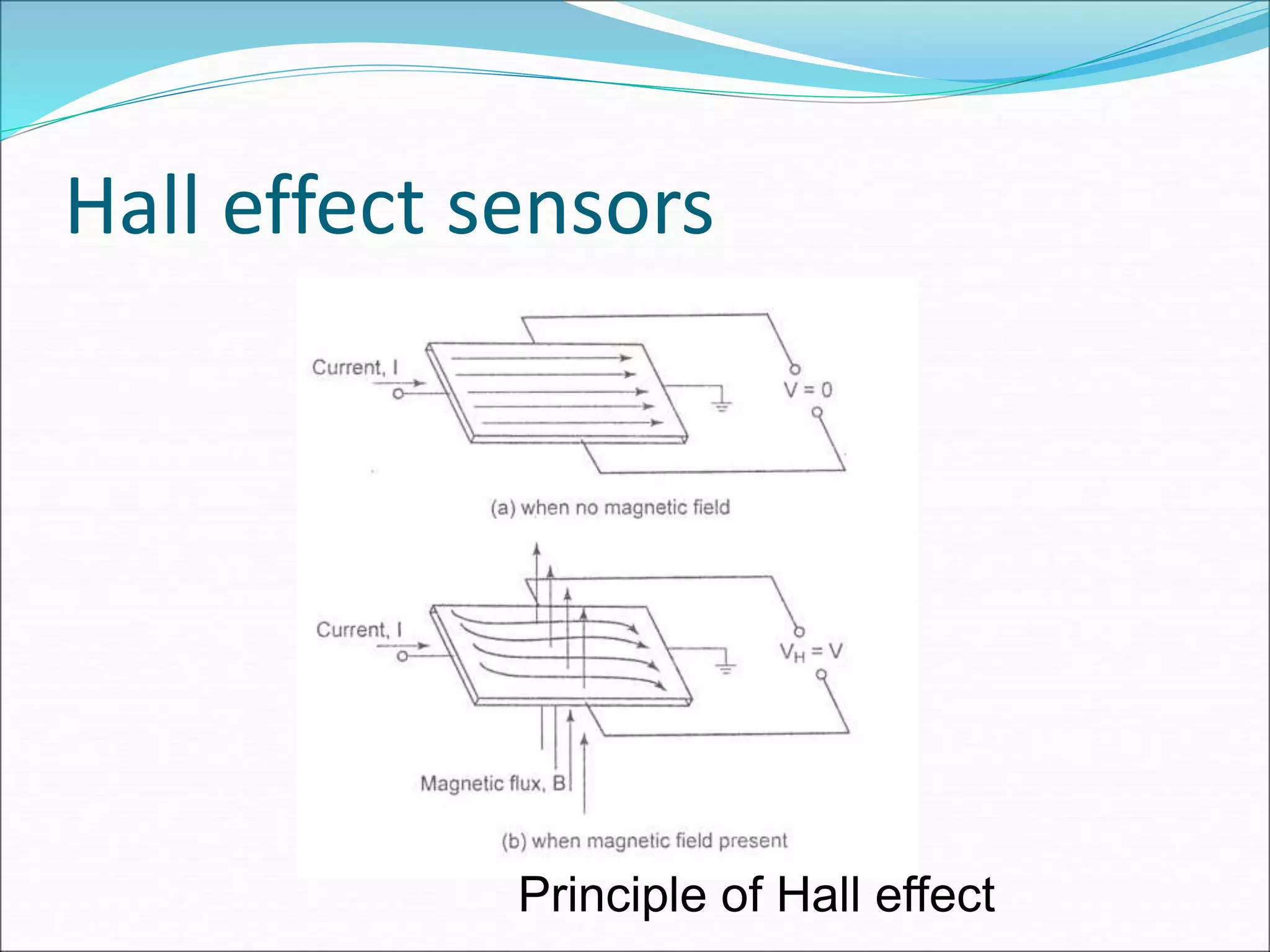

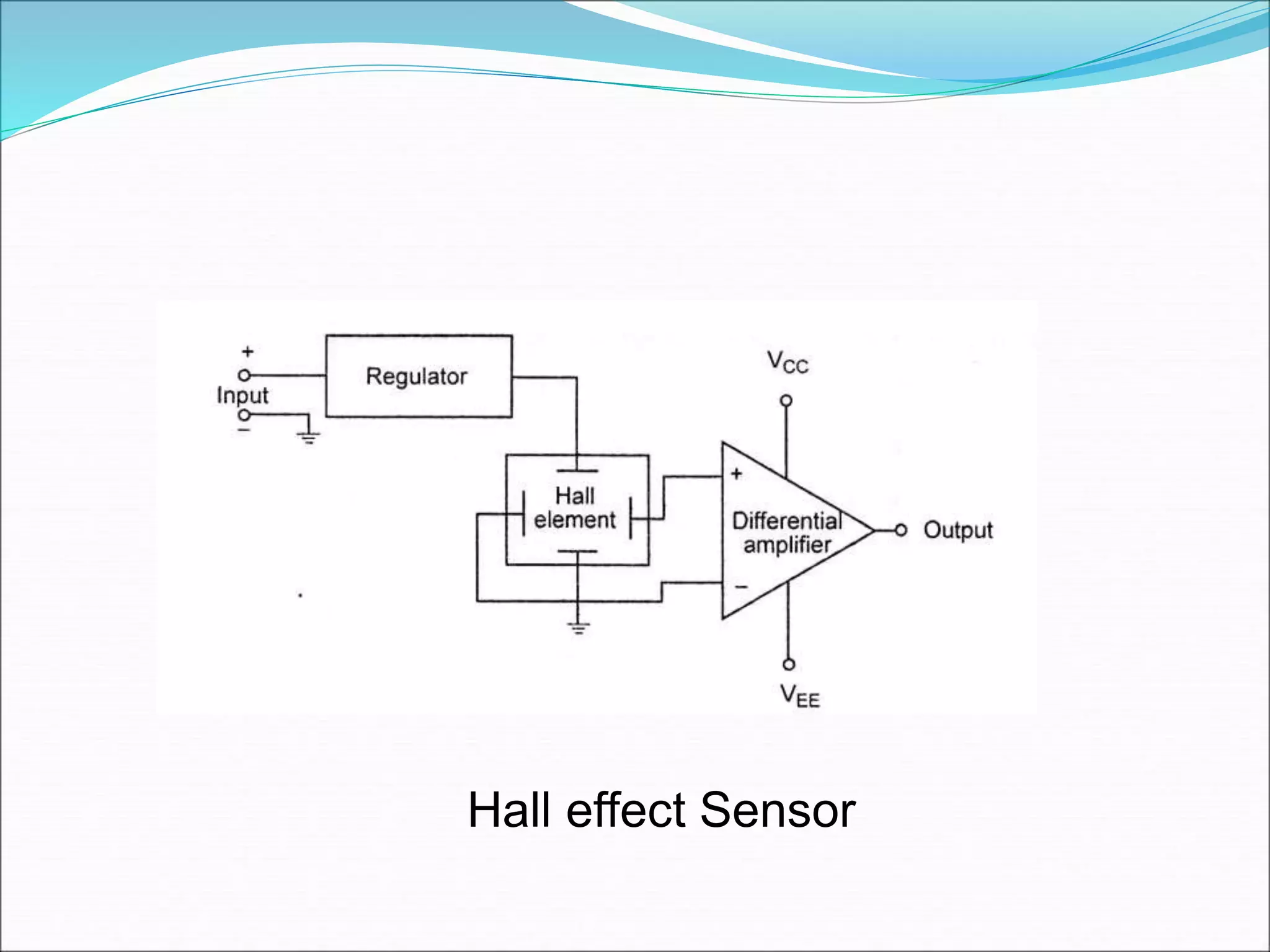

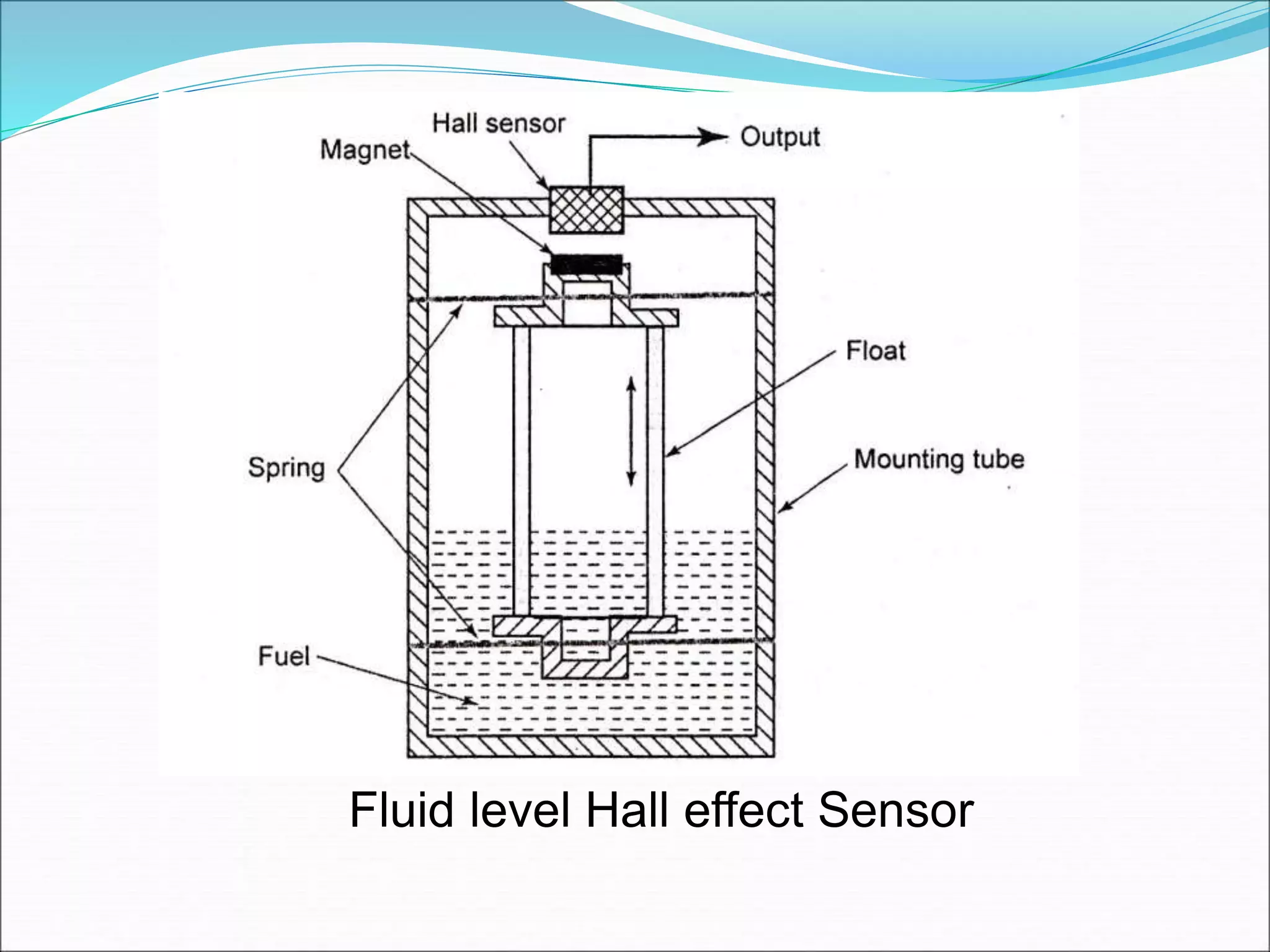

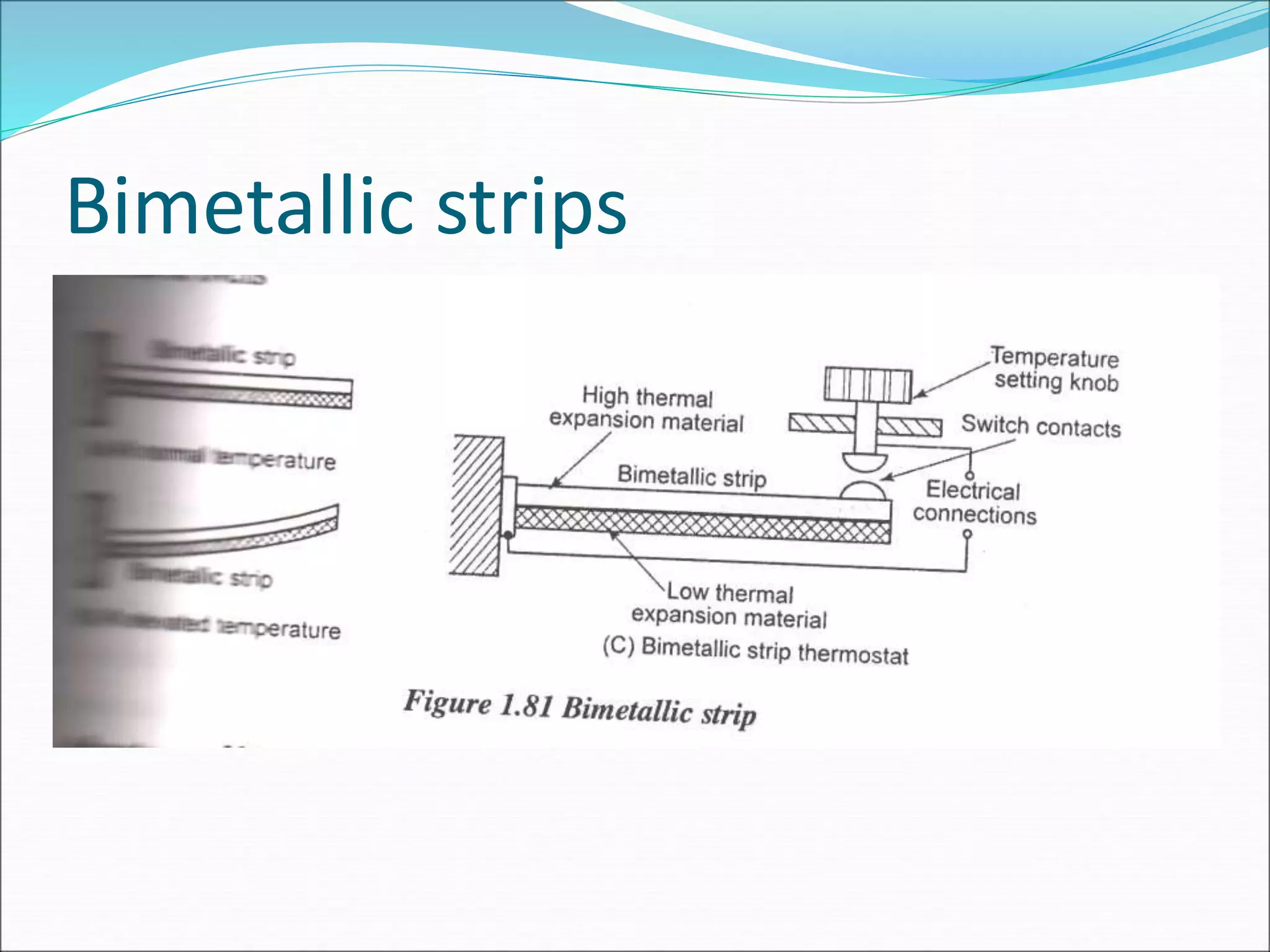

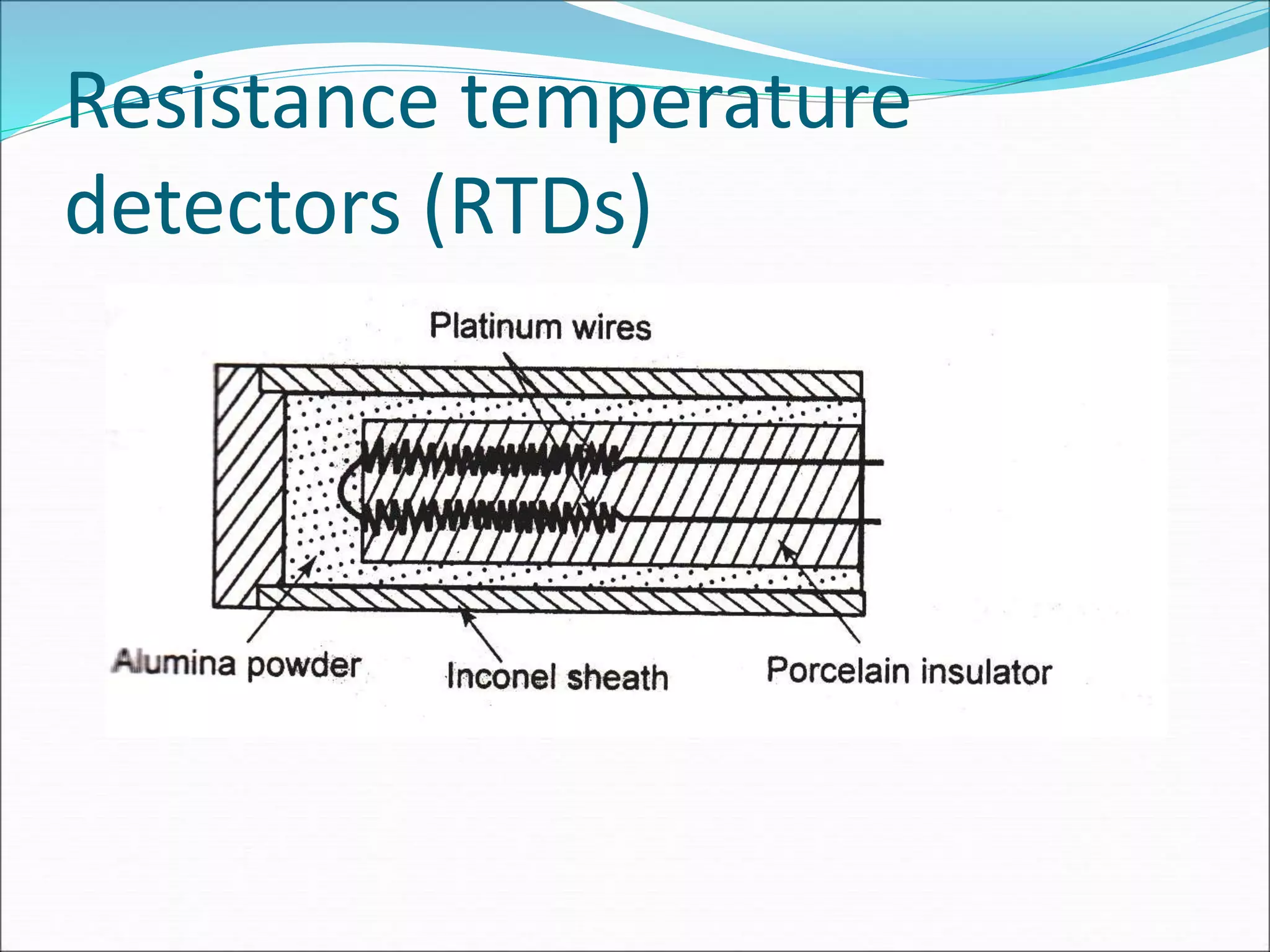

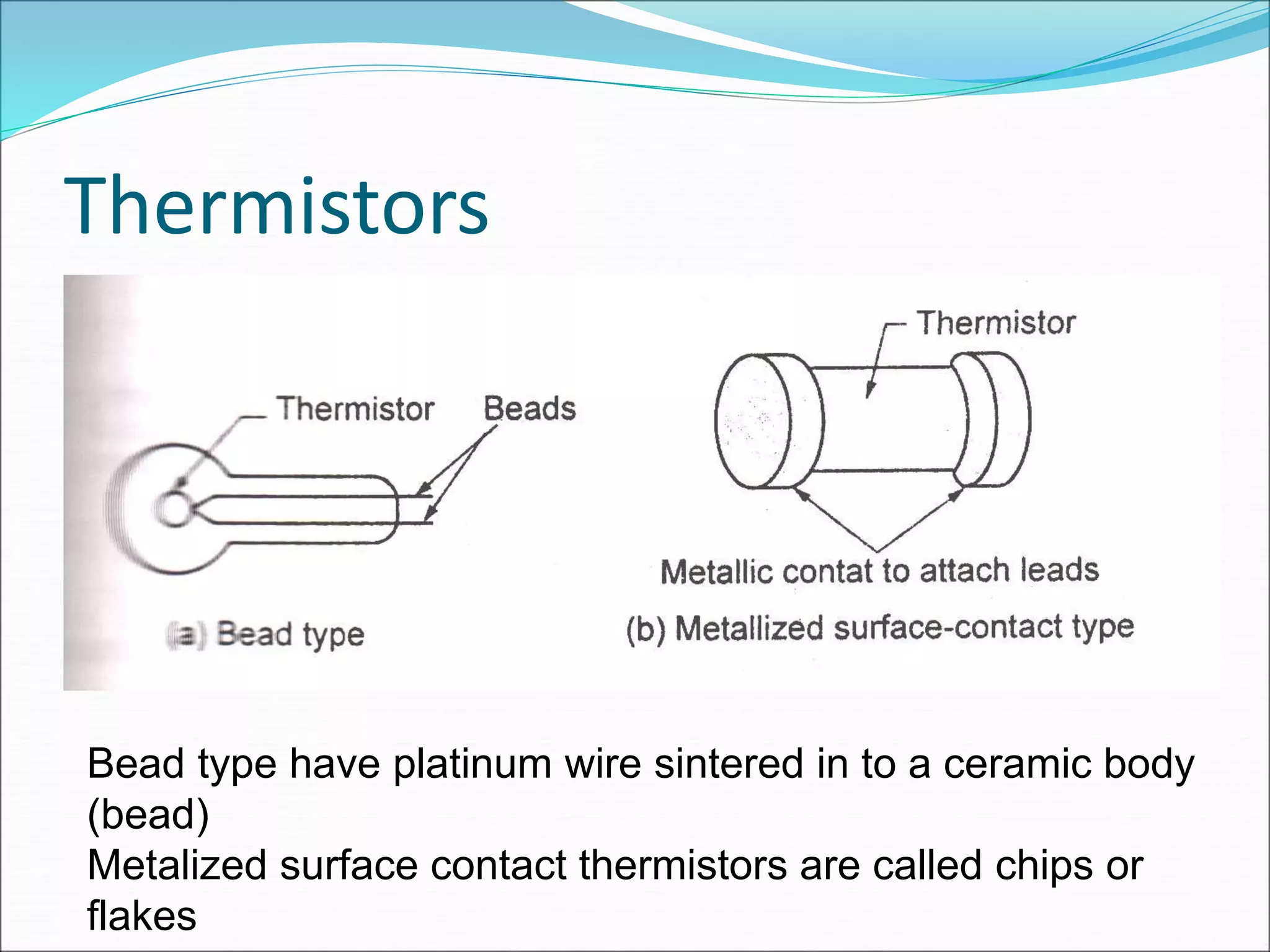

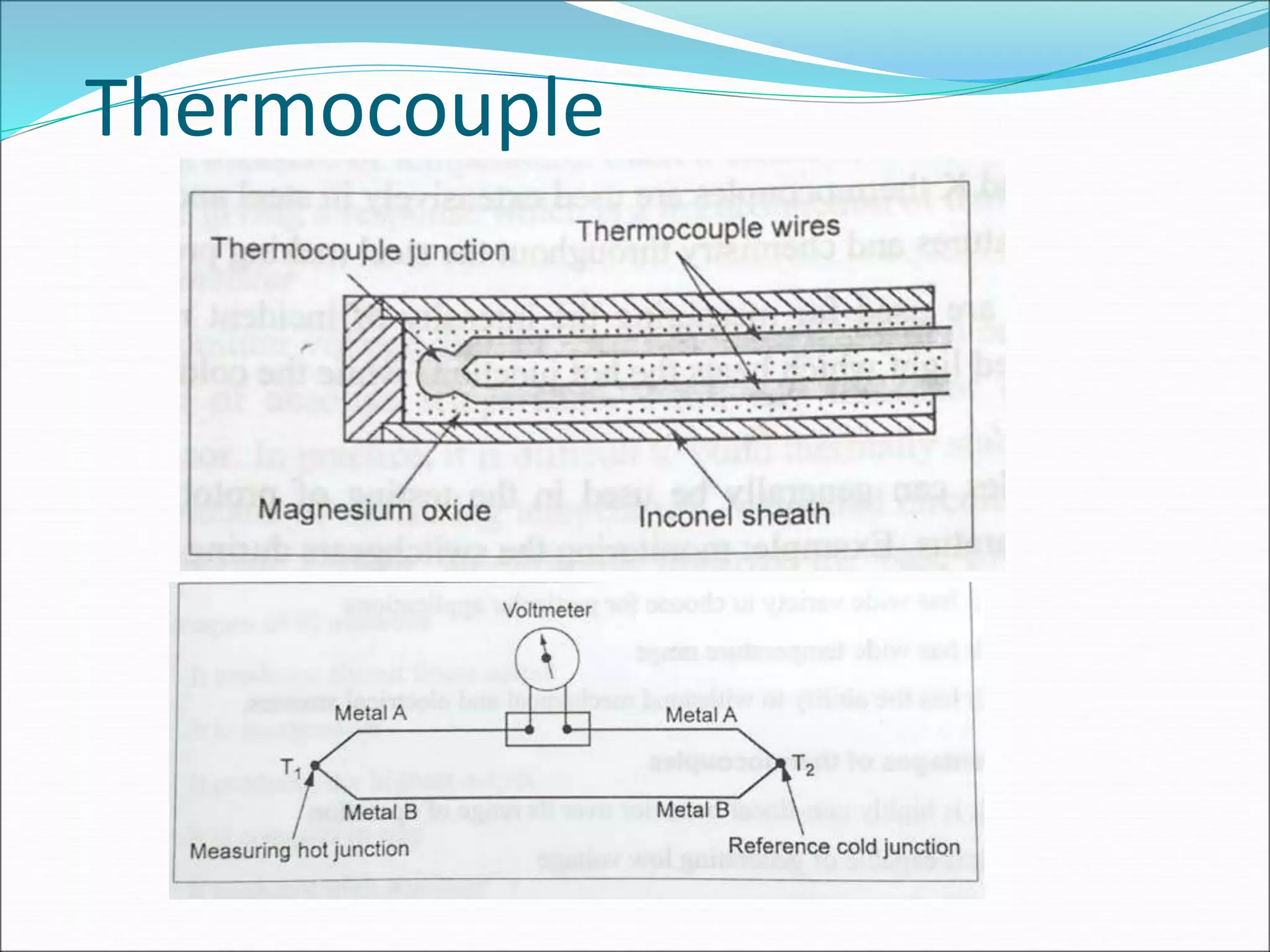

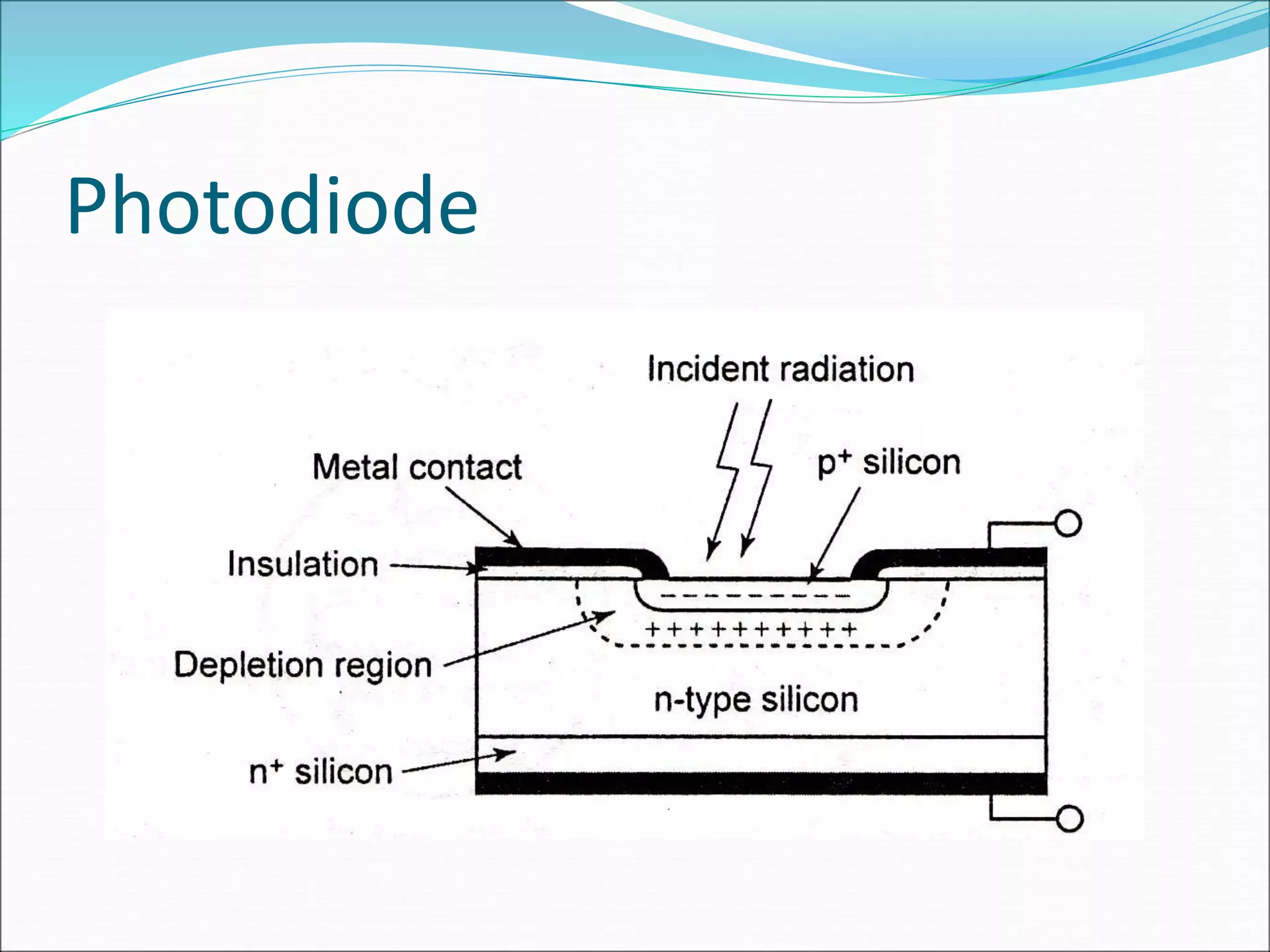

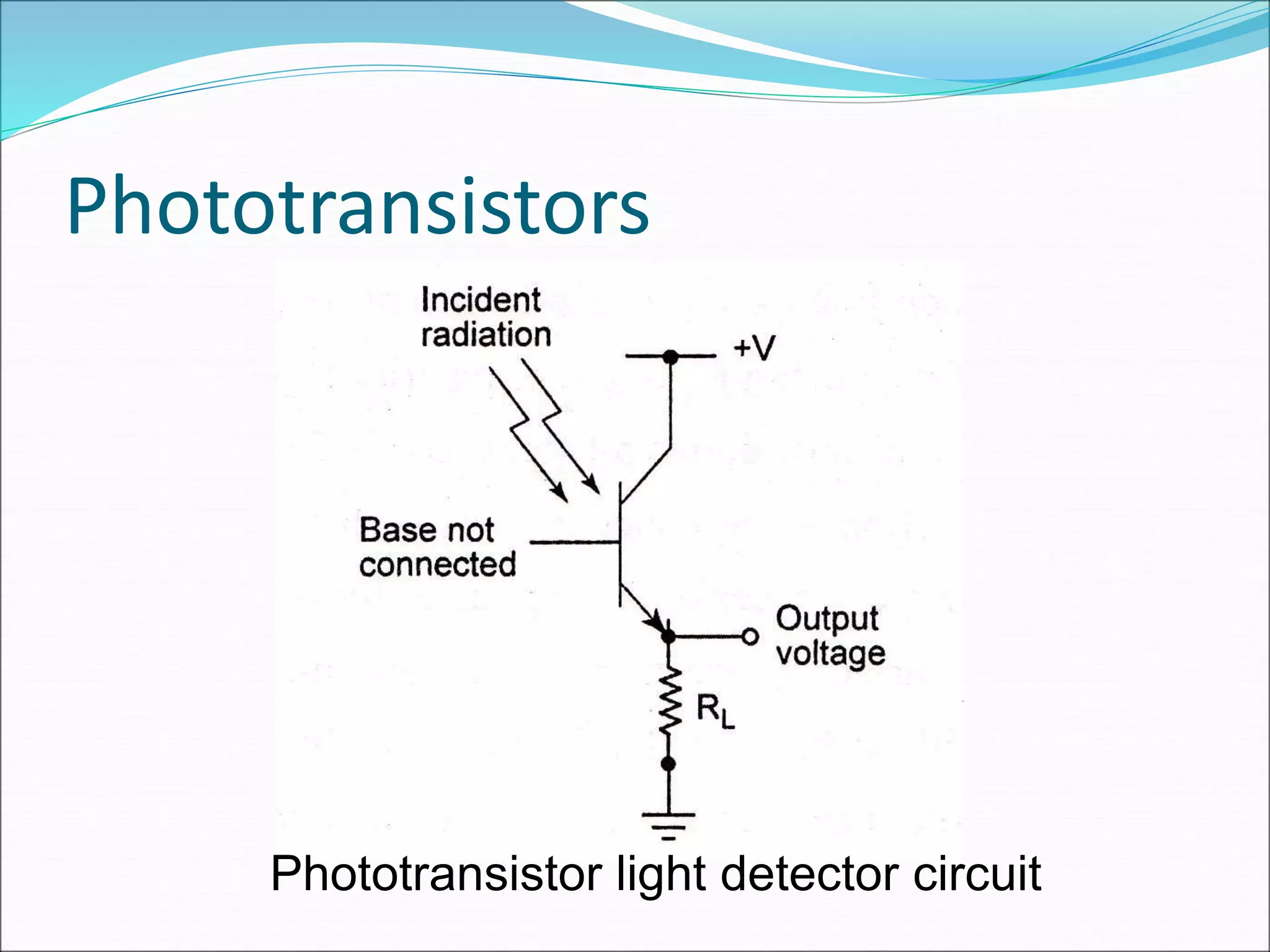

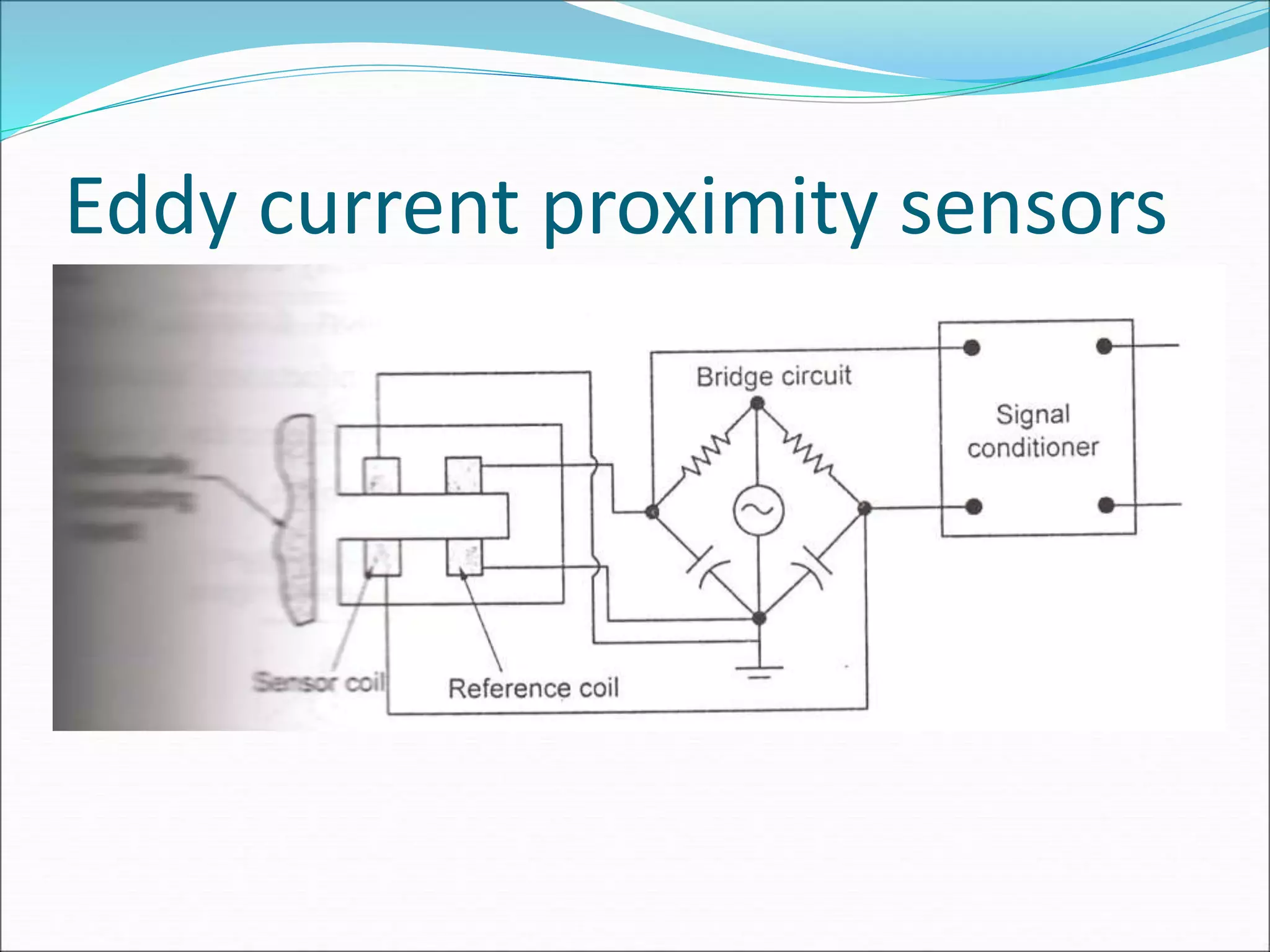

Sensors are devices that produce an output signal in response to a physical input like pressure, temperature, or displacement. Transducers convert one form of energy into another. Sensor performance is characterized by static and dynamic characteristics. Static characteristics include range, accuracy, sensitivity, hysteresis, linearity, repeatability, reproducibility, stability, and resolution. Dynamic characteristics include response time, time constant, rise time, and setting time. Common sensors include displacement, temperature, light, position, fluid level, and proximity sensors that use effects like piezoelectricity, resistance temperature, photoelectricity, and capacitance.